Method for compounding microcrystalline glass materials by means of ferrochrome slags

A technology of ferrochromium alloy and glass-ceramic, applied in the field of synthesizing glass-ceramic materials, can solve the problems of inability to completely separate slag and iron, high melting point, high viscosity of ferrochromium alloy slag, etc., and achieve good performance, uniform microscopic appearance, The effect of solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Ferrochrome alloy slag, waste glass, limestone, soda ash and fluorite are used as raw materials, and the proportions are shown in Table 1. Melting at 1500°C-1550°C under normal pressure for 1-4 hours, and then heat-treating the prepared basic glass to synthesize a slag-like glass-ceramic material. X-ray diffraction analysis and SEM analysis were performed on the synthesized samples.

[0020] Table 1 Raw material ratio and synthesis conditions of synthetic ferrochrome alloy slag glass-ceramic materials

[0021]

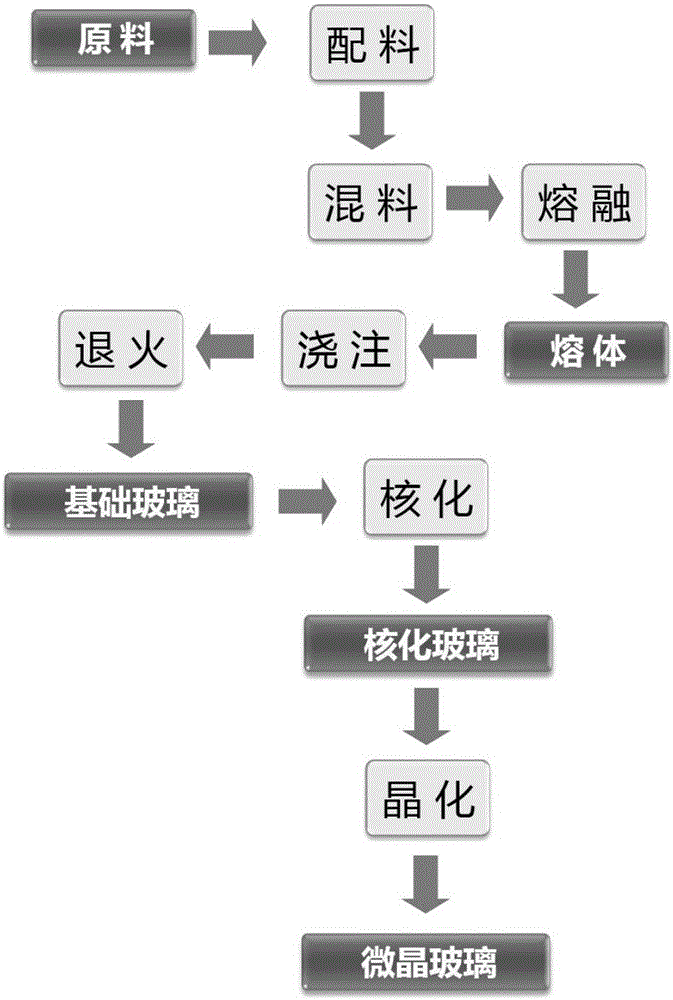

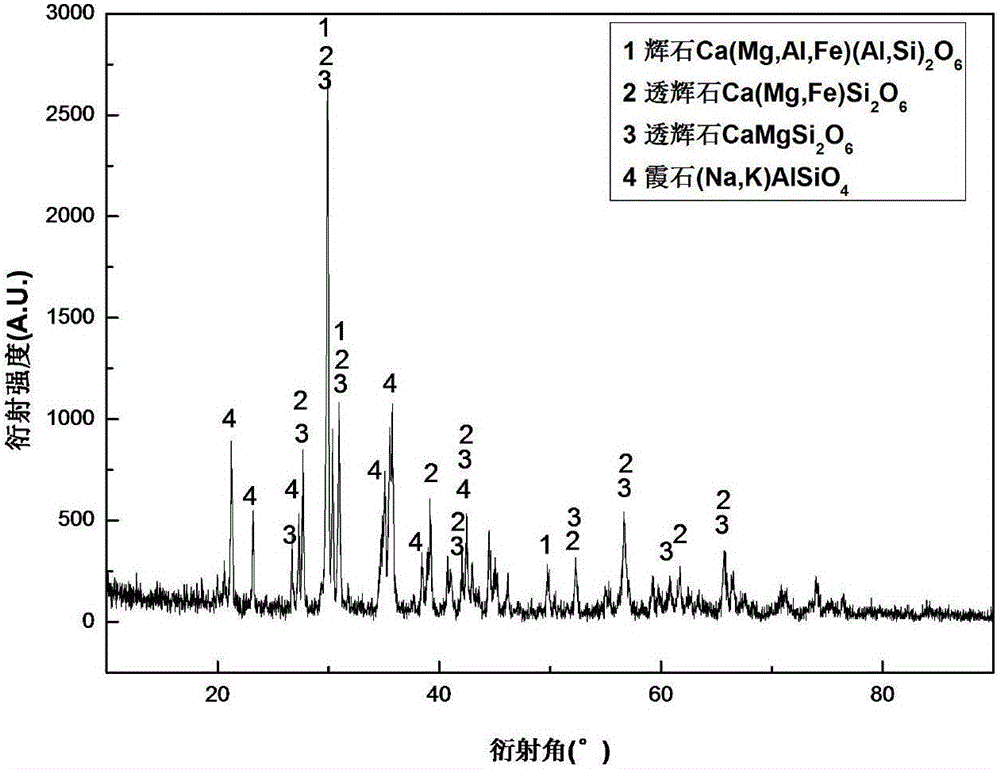

[0022] Design flow charts by preparing, such as figure 1 As shown, ferrochrome alloy slag glass-ceramic materials with different composition ratios have been obtained, and the X-ray diffraction and scanning electron microscope results of the synthesized materials according to the experimental design are shown in Fig. figure 2 , image 3 As shown, it can be seen from the figure that the main crystal phases of the synthetic materials are diopside and nephel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com