Preparation method of potassium titanate and application of potassium titanate in friction material

A friction material, potassium titanate technology, applied in the direction of titanate, friction lining, alkali metal titanate, etc., can solve the problems of low thermal fading resistance, unstable braking at high temperature, and loud braking noise , to achieve good wear resistance, good brake imaging ability, and reduce the effect of brake imaging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

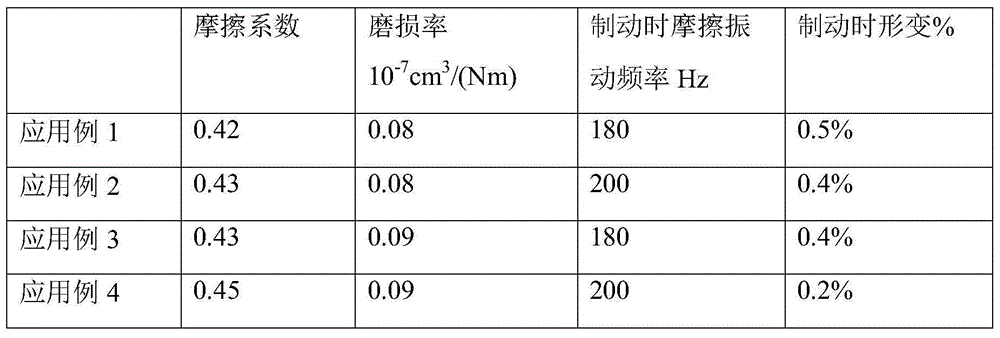

Examples

Embodiment 1

[0012] Mix 80g of titanium dioxide and 1.5g of potassium carbonate for 15-20 minutes, stir evenly and transfer to the pusher pit;

[0013] First, heat the furnace temperature from room temperature, raise it to 300-320°C in 2 hours, then raise the temperature again, raise it to 700-720°C in 6 hours, keep it warm for 8 hours, then heat it up to 900-920°C for 4 hours, and keep it warm for 4 hours;

[0014] Then start to cool down, first naturally cool down to 800°C, keep for 2 hours; then naturally cool down to 200°C, keep for 2 hours, and finally cool down to room temperature naturally.

[0015] Then take out and pulverize, first coarse powder, control the particle diameter to be less than 1 cm; ball mill the material after coarse powder for 10-20 hours, after ball milling, heat treatment at 700°C-800°C for 1 hour to obtain potassium titanate.

Embodiment 2

[0017] Mix 80g of titanium dioxide and 1g of potassium carbonate for 15 to 20 minutes, stir evenly and transfer to the pusher pit;

[0018] First, heat the furnace temperature from room temperature, raise it to 300-320°C in 2 hours, then raise the temperature again, raise it to 700-720°C in 6 hours, keep it warm for 8 hours, then heat it up to 900-920°C for 4 hours, and keep it warm for 4 hours;

[0019] Then start to cool down, first naturally cool down to 800°C, keep for 2 hours; then naturally cool down to 200°C, keep for 2 hours, and finally cool down to room temperature naturally.

[0020] Then take out and pulverize, first coarse powder, control the particle diameter to be less than 1 cm; ball mill the material after coarse powder for 10-20 hours, after ball milling, heat treatment at 700°C-800°C for 1 hour to obtain potassium titanate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com