Multi-point positioning locking cylinder body tool structure and technological method thereof

A multi-point positioning and cylinder technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of poor safety factors, high manufacturing costs, and inability to ensure the balance of workpiece hoisting, etc., to achieve firm clamping and low manufacturing costs , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

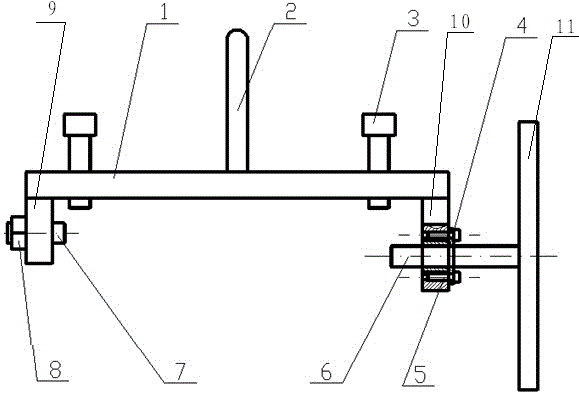

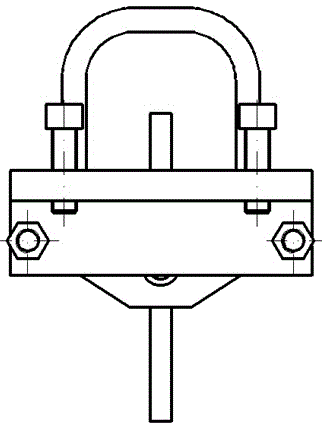

[0029] Embodiment 1, a multi-point positioning and locking cylinder block tooling structure and its process method, including a suspension head, a beam, a bolt, a screw, a screw sleeve, a right clamping arm, a left clamping arm, a nut, a left boom, and a right boom , Rotate the handle. The beam (2) is fixedly connected with the hanger (1), and the hanger (1) is welded by three iron plates; the right side of the hanger (1) is installed with a replaceable screw sleeve (5 ); the screw sleeve (5) is fixed on the right side of the suspension head (1) by four screws; the clamp arm includes a left clamp arm (7) and a right clamp arm (6); the left clamp arm (7) ) is fixed on the left side of the suspension head (1), and the right clamping arm (6) is threaded and locked from the side through the screw hole fixed on the right side of the suspension head (1) at 90°; the right clamping arm (6) is connected with The screw sleeve (5) installed on the right side of the hanger (1) cooperates...

Embodiment 2

[0030] Example 2, such as Figure 1 to Figure 9 As shown, a multi-point positioning and locking cylinder block tooling device of the present invention

[0031] The structure and its process method include suspension head, beam, left and right clamping arms. The hanger (1) is connected with the beam (2) by welding. The hanging head (1) is welded and connected by three iron plates, the right side of the hanging head (1) is equipped with a replaceable screw sleeve (5), and the screw sleeve (5) is fixed on the right side of the hanging head (1) by four screws; The clamping arm includes a left clamping arm (7) and a right clamping arm (6). The left and right clamping arms (7, 6) are symmetrically installed on both sides of the suspension head (1) through screw holes. The left clamping arm (7) is used for The nut (8) is fixed on the left side of the hanger head (1), and the right jig arm (6) is locked by the screw sleeve (5) installed on the right side of the hanger head (1) by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com