Connecting structure for tire pressure monitoring sensor and inflating valve

A technology of tire pressure monitoring and connection structure, which is applied in tire measurement, tire inflation valve, tire parts, etc. It can solve the problems of falling off, poor connection reliability, loosening of electronic signal box and valve, and achieves convenient operation and simple structure , The effect of stabilizing the connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

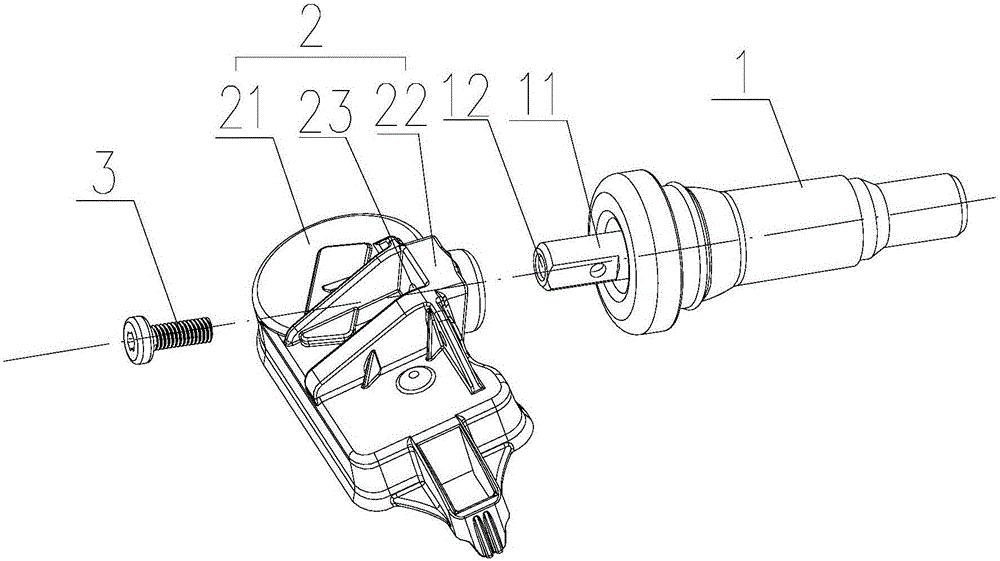

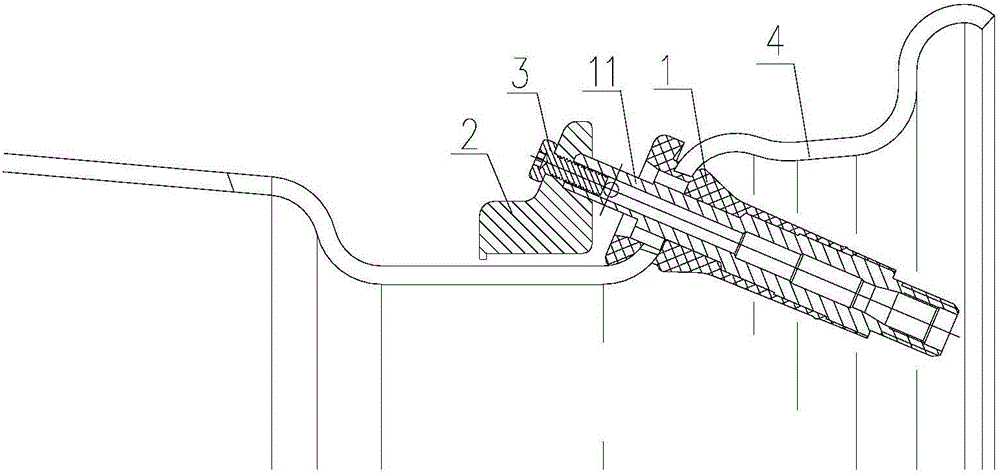

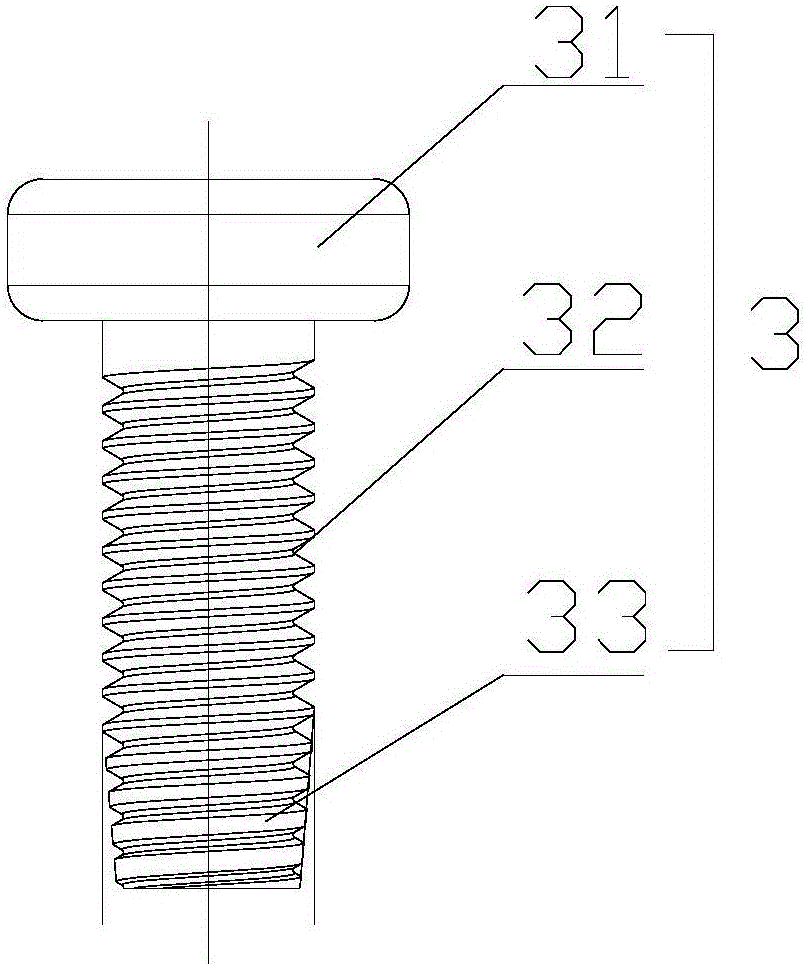

[0018] like Figures 1 to 3 shown, figure 1 It is a schematic structural diagram of the connection structure of a tire pressure monitoring sensor and a valve proposed by the present invention, figure 2 for figure 1 The schematic diagram of the connection structure of the middle tire pressure monitoring sensor and the valve mounted on the rim, image 3 for figure 1 Schematic diagram of the structure of the self-tapping screw.

[0019] refer to figure 1 , a connection structure between a tire pressure monitoring sensor and a valve proposed by an embodiment of the present invention includes: a valve 1, a tire pressure monitoring sensor 2 and a self-tapping screw 3, wherein:

[0020] A mounting hole 12 is coaxially provided on the nozzle rod 11 of the valve 1, and the mounting hole 12 has a smooth inner wall; a mounting table 22 is provided on the electronic signal box 21 of the tire pressure monitoring sensor 2, and a through hole 12 is provided on the mounting table 22. h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com