A portable high-efficiency steel pipe rust removal and grinding machine

A grinding machine and convenient technology, which is applied to the parts of grinding machine tools, machine tools designed for grinding the rotating surface of workpieces, grinding machines, etc. and other problems, to achieve the effect of stable movement, convenient and simple recycling, and speeding up the maintenance rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

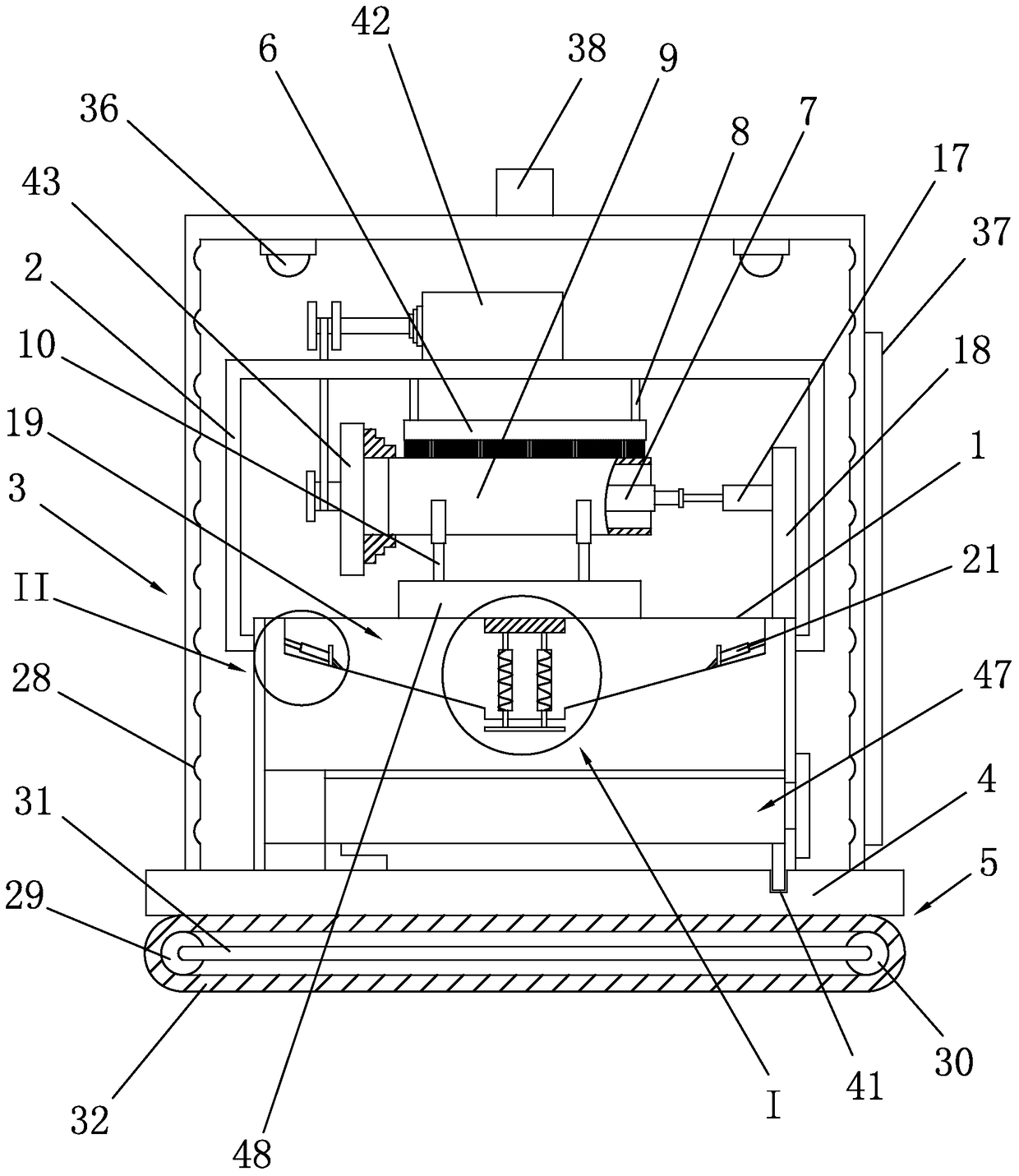

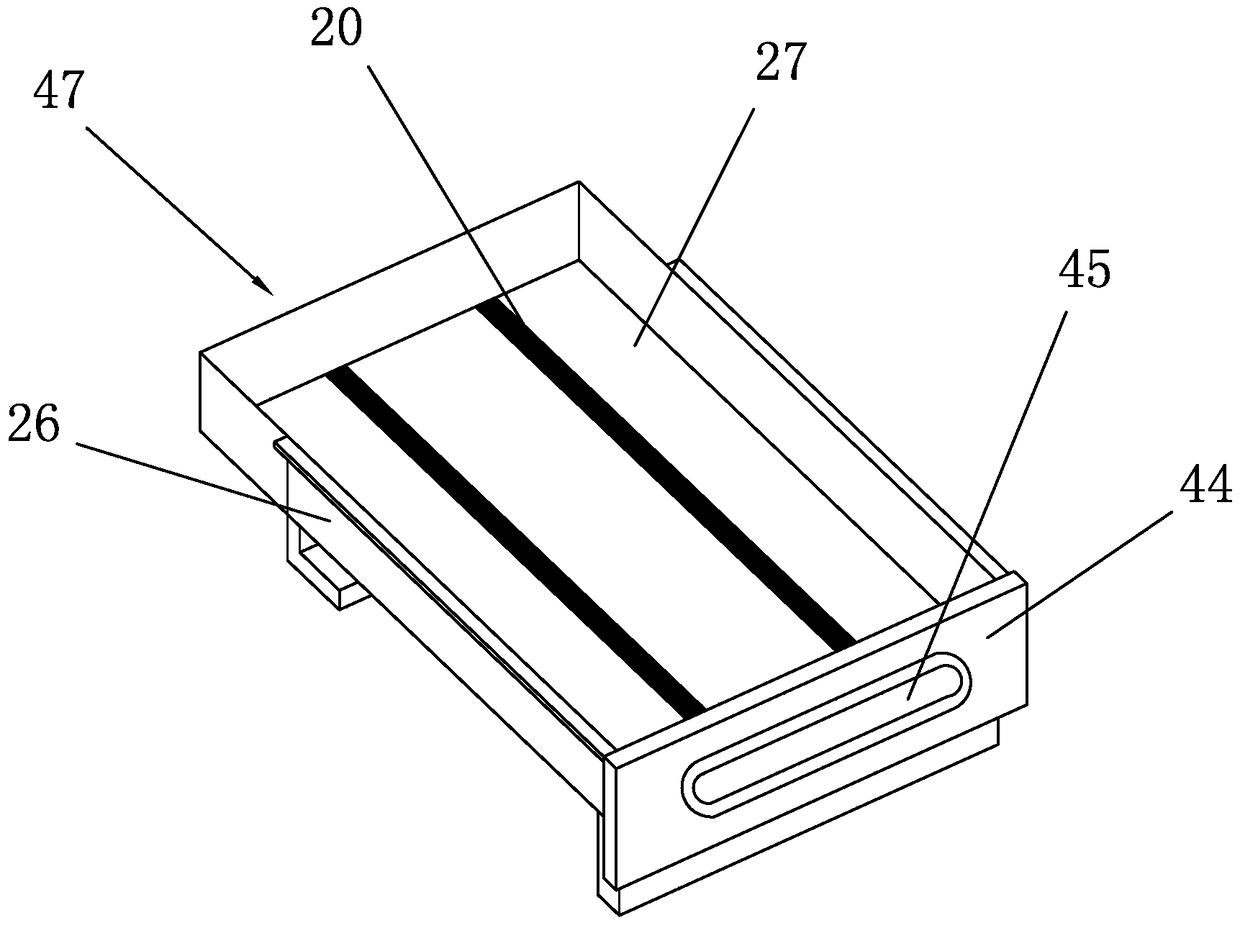

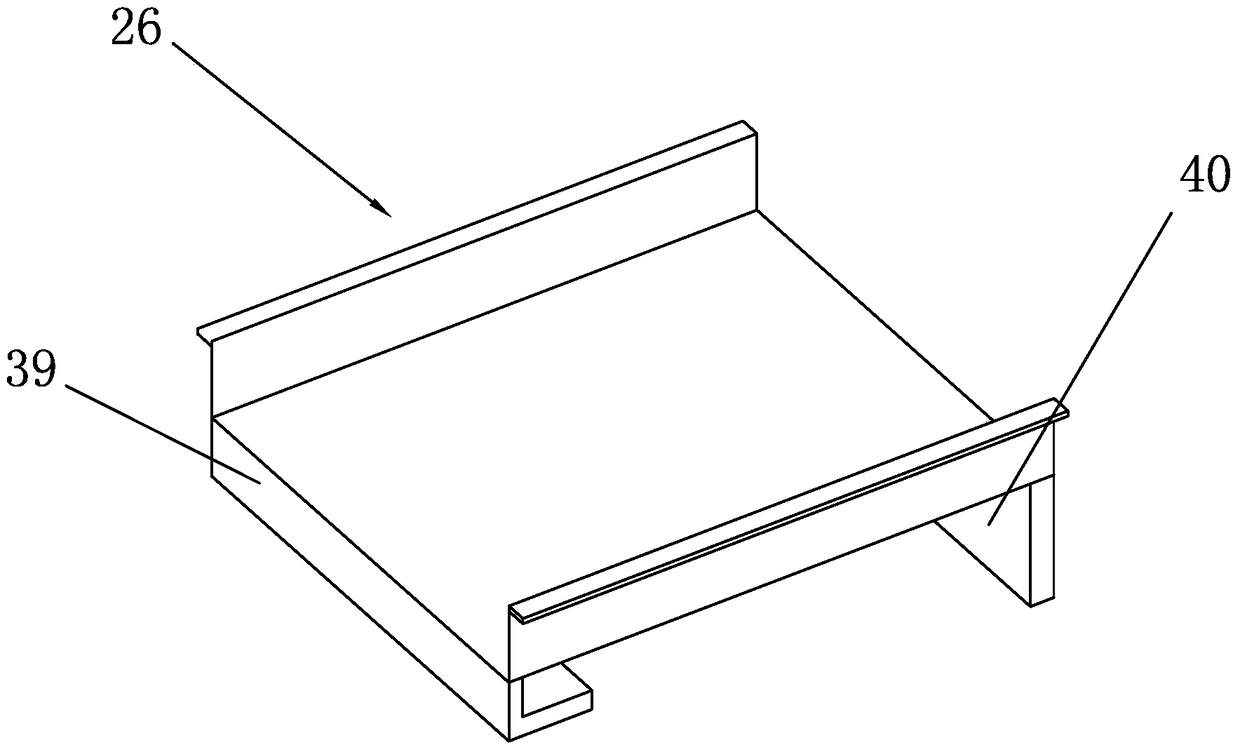

[0033] Such as Figure 1 to Figure 7 As shown, it is a portable high-efficiency steel pipe rust removal and grinding machine of the present invention, including a workbench 1, a motor fixing table 2, a rust removal device, an iron filings cleaning device and a protective cover 3, and a support platform 4 is provided under the workbench 1 , the below of support platform 4 is provided with moving device 5, and moving device 5 comprises driving wheel 29 and driven wheel 30, and driving wheel 29 is connected with driven wheel 30 by connecting shaft 31, and driving wheel 29 drives driven wheel 30 to rotate by rubber belt 32 , the driving wheel 29 drives the moving mode of the driven wheel 30, making the movement of the steel pipe derusting and grinding machine more stable, increasing the safety performance, and the design of the moving device 5 makes the movement of the steel pipe derusting and grinding machine more convenient and simple, further It expands the scope of use of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com