Energy-saving hydrogen decrepitation method

A technology of hydrogen crushing and rotary heating, which is applied in the field of rare earth magnetic material powdering, can solve the problems of high energy costs, low pulverization efficiency, waste of heat, etc., to improve pulverization efficiency and save warm-up time , The effect of reducing energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

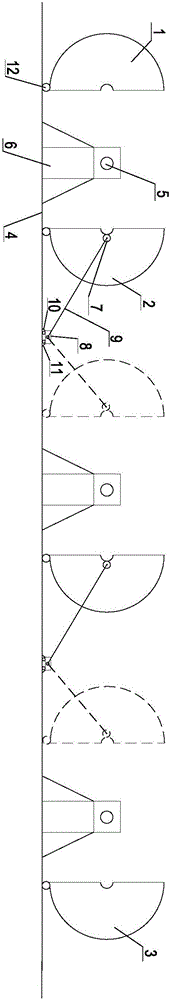

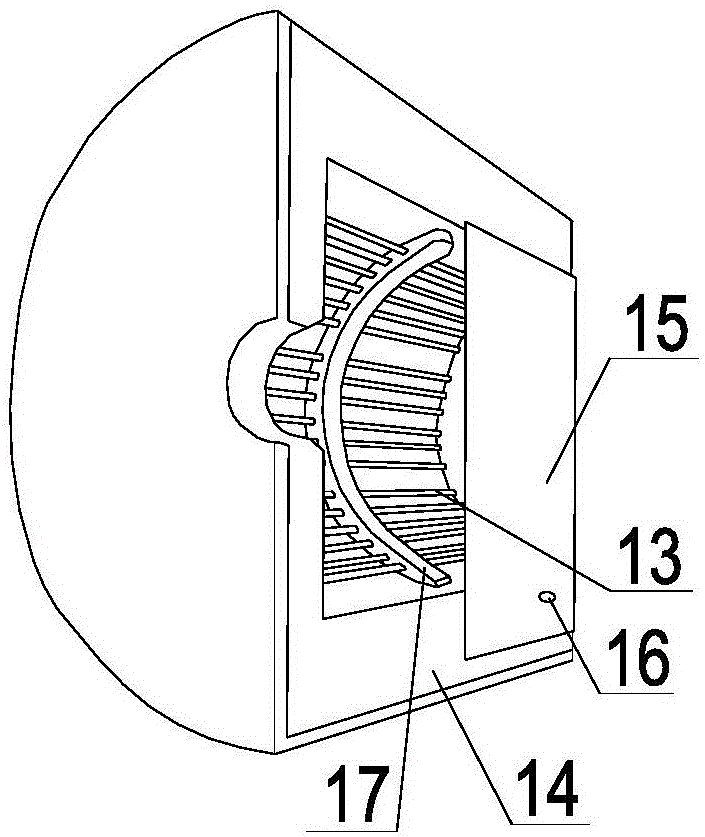

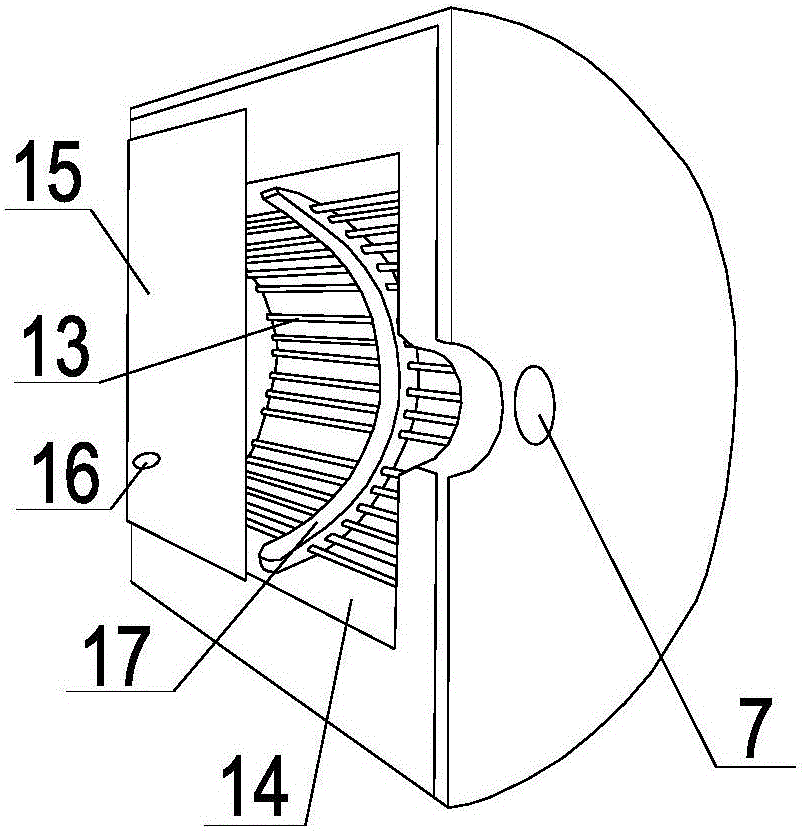

[0019] see Figure 1 ~ Figure 3 An energy-saving hydrogen crushing device, including a front heating chamber 1, a rotating heating chamber 2, a rear heating chamber 3, a guide rail 4, a reaction furnace 5, a reaction furnace installation frame 6, a fixed pin 7, a sliding frame 8, a connecting rod 9, Stop pin 10 before sliding, stop pin 11 after sliding, pulley 12, heating pipe 13, insulation layer 14, baffle plate 15, travel switch 16 and limit frame 17.

[0020] In this embodiment, the front group hydrogen crushing mechanism, the middle group hydrogen crushing mechanism and the rear group hydrogen crushing mechanism are installed on the guide rail 4, wherein the front group hydrogen crushing mechanism includes a front heating chamber 1, a react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com