Preparation method of vanilla extracts for cigarettes

A vanilla extract technology, applied in the field of preparation of tobacco vanilla extract, can solve the problems of high cost, low utilization rate, low vanillin content, etc., to improve efficiency, increase cigarette aroma, improve The effect of smoke smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

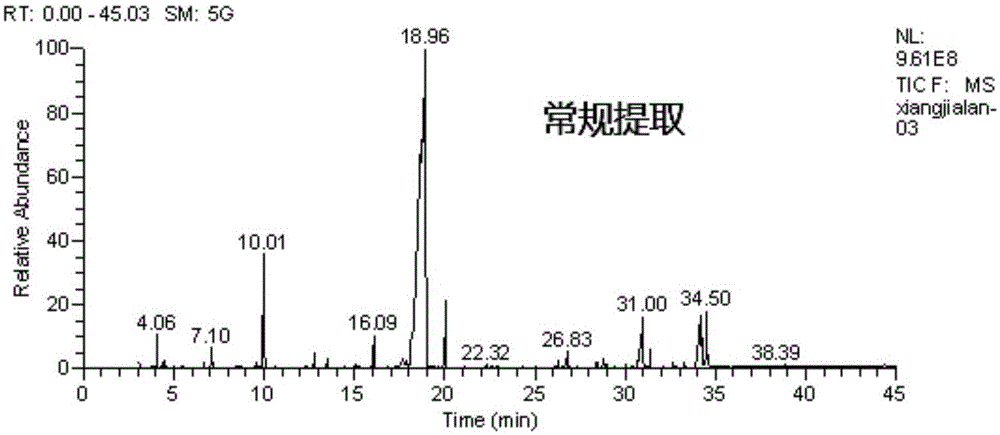

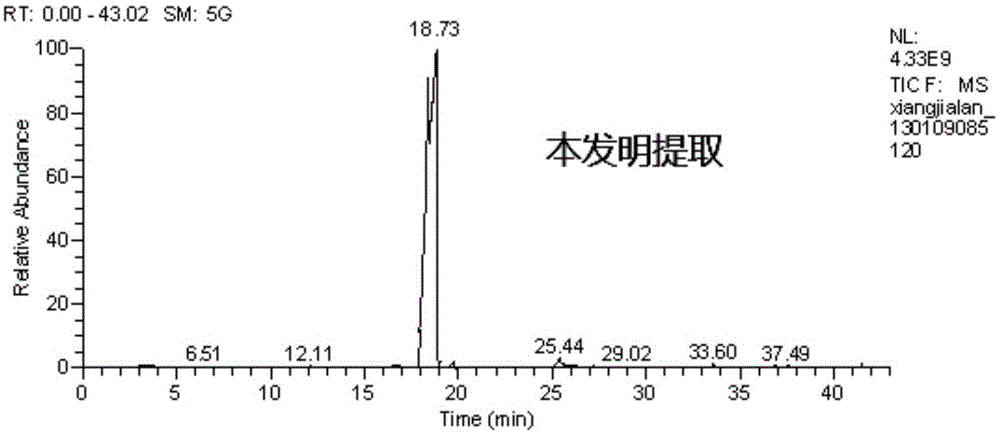

Image

Examples

Embodiment 1

[0021] The preparation method of tobacco vanilla extract comprises the following steps:

[0022] 1) Chop the vanilla pods into 1cm particles, weigh 350g of the vanilla pods, put the vanilla pods into a pressure vessel, raise the pressure to 3MPa at room temperature, and keep it for 5 minutes After that, the pressure is released to normal pressure instantaneously, so that the vanilla pod particles are fluffy;

[0023] 2) adding ethanol with a mass percentage concentration of 75% into the fluffy vanilla bean pod particles to obtain a mixed solution, the quality of ethanol is 2 times the weight of the vanilla bean pod particles, and then the mixed solution is ultrasonically treated, ultrasonically The processing time is 10min, the ultrasonic power is 150W / L, and the ultrasonic frequency is 20kHz;

[0024] 3) Centrifuge the ultrasonically treated mixed solution, take the supernatant, and centrifuge for 10 minutes at a speed of 500 rpm;

[0025] 4) refrigerating the supernatant a...

Embodiment 2

[0028] The preparation method of tobacco vanilla extract comprises the following steps:

[0029] 1) Chop the vanilla pods into 2cm particles, weigh 350g of the vanilla pods, put the vanilla pods into a pressure vessel, raise the pressure to 5MPa at room temperature, and keep it for 10 minutes After that, the pressure is released to normal pressure instantaneously, so that the vanilla pod particles are fluffy;

[0030] 2) adding ethanol with a mass percentage concentration of 90% into the fluffy vanilla pod particles to obtain a mixed solution, the quality of ethanol is 3 times the weight of the vanilla pod particles, and then the mixed solution is ultrasonically treated, ultrasonically The processing time is 20min, the ultrasonic power is 200W / L, and the ultrasonic frequency is 20kHz;

[0031] 3) Centrifuge the ultrasonically treated mixed solution, take the supernatant, and centrifuge for 20 minutes at a speed of 1000 rpm;

[0032] 4) refrigerating the supernatant at -2°C f...

Embodiment 3

[0035] The preparation method of tobacco vanilla extract comprises the following steps:

[0036] 1) Chop the vanilla pods into 4cm particles, weigh 350g of the vanilla pods, put the vanilla pods into a pressure vessel, and raise the pressure to 8MPa at room temperature for 20 minutes After that, the pressure is released to normal pressure instantaneously, so that the vanilla pod particles are fluffy;

[0037] 2) Adding ethanol with a mass percentage concentration of 95% into the fluffy vanilla pod particles to obtain a mixed solution, the quality of ethanol is 5 times the weight of the vanilla pod particles, and then the mixed solution is ultrasonically treated, ultrasonically The treatment time is 30min, the ultrasonic power is 250W / L, and the ultrasonic frequency is 25kHz;

[0038] 3) Centrifuge the ultrasonically treated mixed solution, take the supernatant, and centrifuge for 30 minutes at a speed of 2000 rpm;

[0039] 4) The supernatant was refrigerated at 4°C for 24 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com