Heating device capable of simultaneously heating from bottom part and lateral parts and heating method

A heating device and side technology, applied in the direction of electric heating devices, ohmic resistance heating, heating element materials, etc., can solve the problems of sticky pot, high cost, complicated operation, etc., achieve enhanced stability and durability, and increase infrared emissivity , The effect of increasing the heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

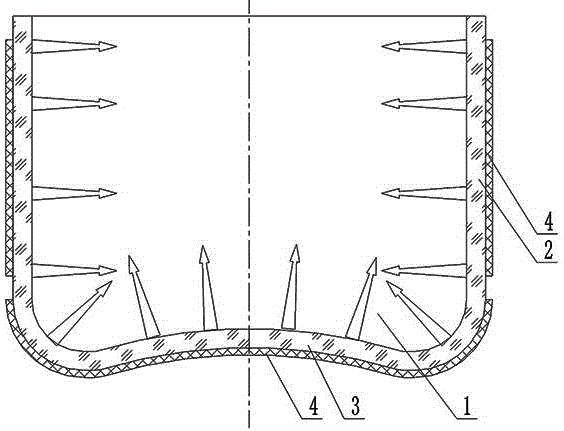

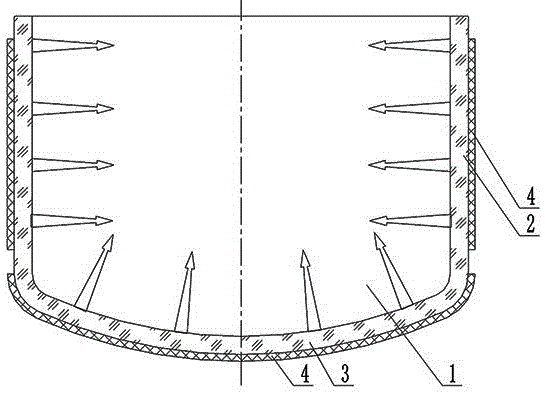

[0081] like figure 1 As shown, a heating device for simultaneously heating the bottom and the side, comprising a cylindrical base 1 with an upper opening, the base 1 includes a cylindrical side wall 2 and a bottom plate arranged at the bottom of the cylindrical side wall 2 3. The outer surface of the side wall 2 and the lower surface of the bottom plate 3 are provided with an electrothermal film 4, and the electrothermal film 4 is made of the following components by weight:

[0082] Tin tetrachloride 30~50,

[0083] Titanium trichloride 0.8~1.2,

[0084] Antimony trichloride 12~18,

[0085] Calcium dichloride 1.5~2.5,

[0086] Chromium trioxide 0.8~1.2,

[0087] Manganese dioxide 0.8~1.2,

[0088] Nickel trioxide 0.8~1.2,

[0089] Isopropanol 8~12,

[0090] Ethanol 3~5,

[0091] Water 20~30;

[0092] The stability of the electric heating film 4 is improved by adding antimony, the temperature resistance of the electric heating film 4 is improved by adding titanium, the...

example 1

[0103] The electrothermal film 4 is made of the following components by weight:

[0104] Tin tetrachloride 40, titanium trichloride 1, antimony trichloride 15, calcium dichloride 2, chromium trioxide 1, manganese dioxide 1, nickel trioxide 1, isopropanol 10, ethanol 4, water 25;

[0105] Its preparation method is:

[0106] S1. Weigh each component according to the above weight ratio, mix the weighed components, and continue to stir until all the solids are dissolved and the components are mixed evenly to obtain the electrothermal film treatment solution;

[0107] S2. Transport the substrate 1 into the heating chamber, the temperature in the heating chamber is controlled at 600°C, after the substrate 1 is heated to 600°C, atomize the electrothermal film treatment liquid through the spray gun and spray it on the outside of the side wall 2 of the substrate 1 respectively The surface and the lower surface of the bottom plate 3 form an electrothermal film semi-finished product, a...

example 2

[0111] The electrothermal film 4 is made of the following components by weight:

[0112] Tin tetrachloride 30, titanium trichloride 1.2, antimony trichloride 12, calcium dichloride 1.5, chromium trioxide 1.2, manganese dioxide 0.8, nickel trioxide 1.2, isopropanol 8, ethanol 5, water 20;

[0113] Its preparation method is:

[0114] S1. Weigh each component according to the above weight ratio, mix the weighed components, and continue to stir until all the solids are dissolved and the components are mixed evenly to obtain the electrothermal film treatment solution;

[0115] S2. Transport the substrate 1 to the heating chamber, the temperature in the heating chamber is controlled at 400°C, after heating the substrate 1 to 400°C, atomize the electrothermal film treatment liquid through the spray gun and spray it on the outside of the side wall 2 of the substrate 1 respectively The surface and the lower surface of the bottom plate 3 form an electrothermal film semi-finished produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com