Simple detachable dry filter

A filter and drying technology, which is applied in the direction of refrigeration components, refrigerators, lighting and heating equipment, etc., can solve the problem of poor sealing of the joints of dry filters, increase the cost of maintenance of refrigeration equipment, and liquid supply to evaporators Insufficient and other problems, achieve stable adsorption effect, simple structure, and improve drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

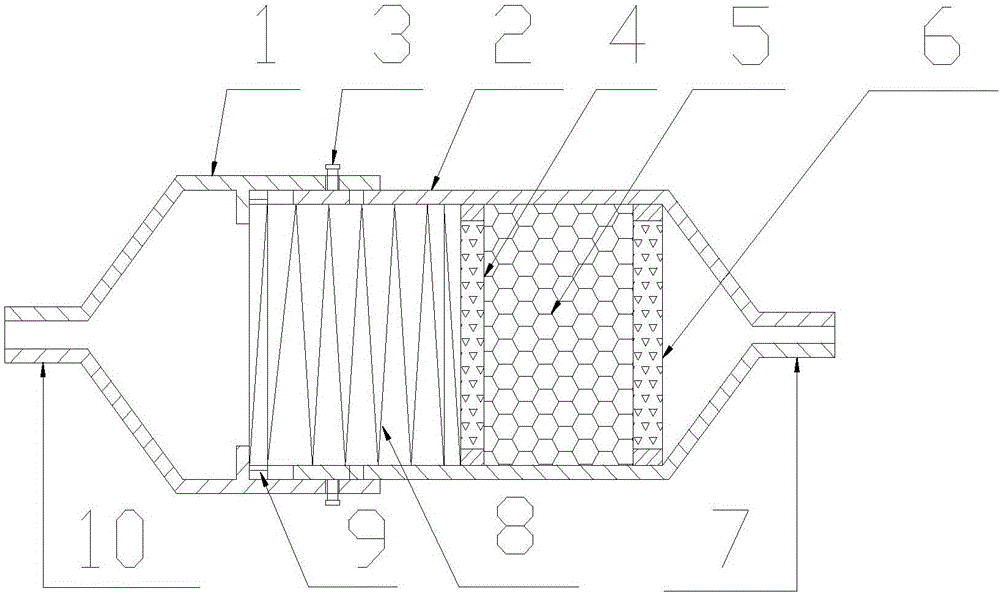

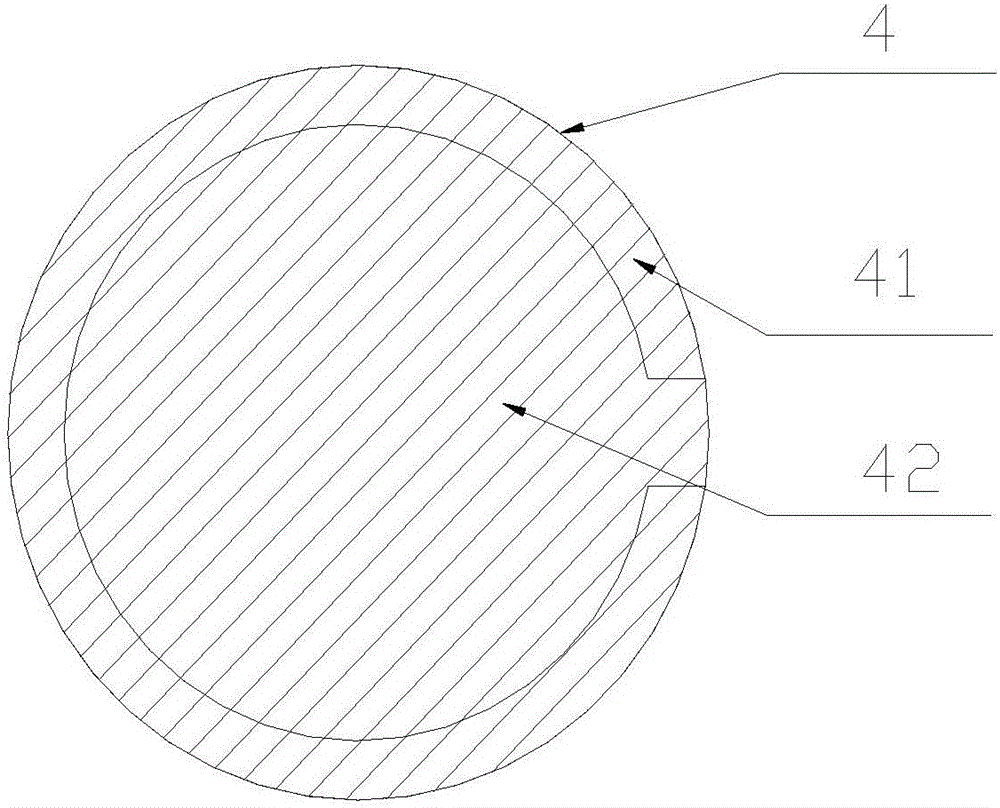

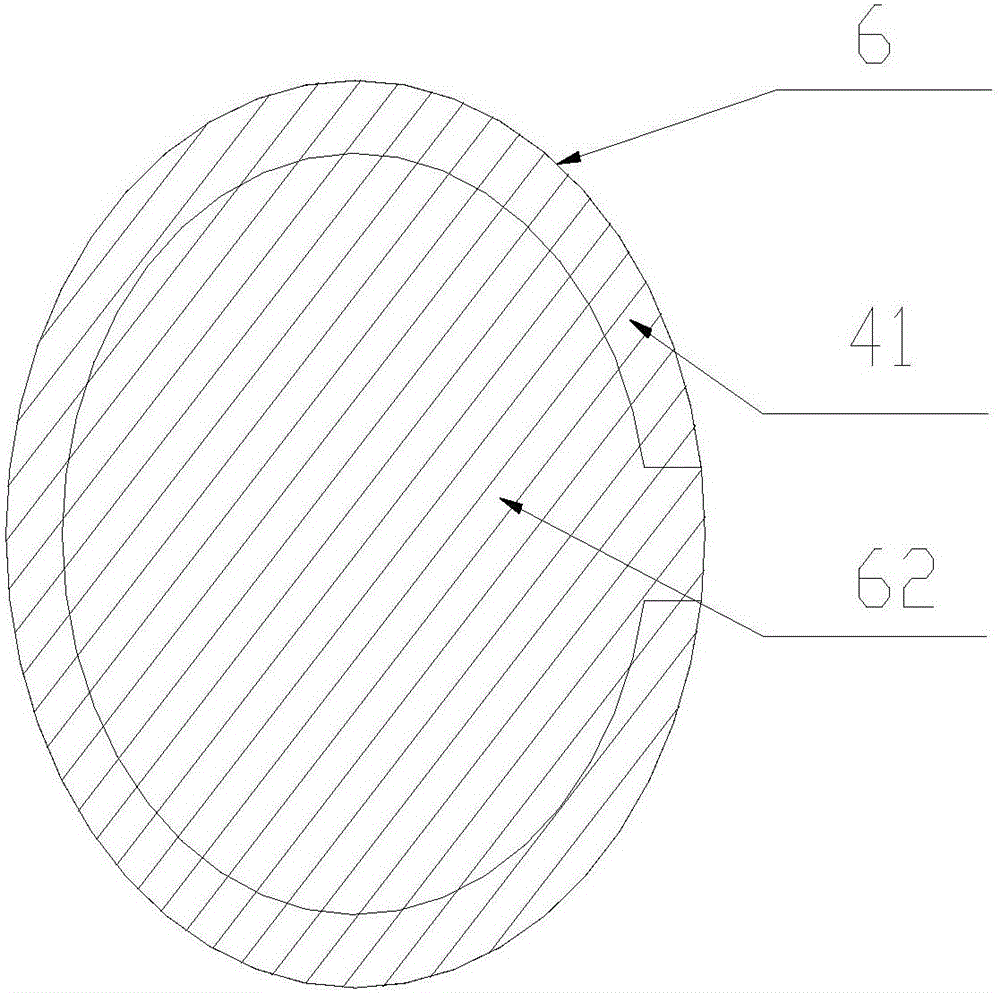

[0016] refer to figure 1 , figure 2 with image 3 , a simple detachable filter drier of the present invention, comprising filter drier cylinder a1, filter drier cylinder b2, fixing screw 3, fine metal mesh 4, molecular sieve 5, coarse metal mesh 6, refrigerant inlet 7, Spring 8, sealing ring 9 and refrigerant outlet 10, the dry filter cylinder a1 and the dry filter cylinder b2 are connected by fixing screws 3, the fine metal mesh 4, molecular sieve 5 and coarse metal mesh 6 are directly Fixed in the dry filter cylinder b2, the spring 8 is installed between the fine metal mesh 4 and the dry filter cylinder a1, and the sealing ring 9 is fixed between the dry filter cylinder a1 and the dry filter cylinder b2 In between, the dry filter cylinder a1 and the dry filter cylinder b2 are respectively provided with a refrigerant outlet 10 and a refrigerant inlet 7, and the inner diameter of the dry filter cylinder a1 is larger than that of the dry filter cylinder b2 The outer diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com