Method for reducing emission of PM2.5 in iron ore sintering flue gas

A technology for sintering flue gas and emissions, applied in the field of iron and steel metallurgy, can solve the problems of huge environmental protection pressure, difficult to capture by electrostatic precipitators, etc., and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

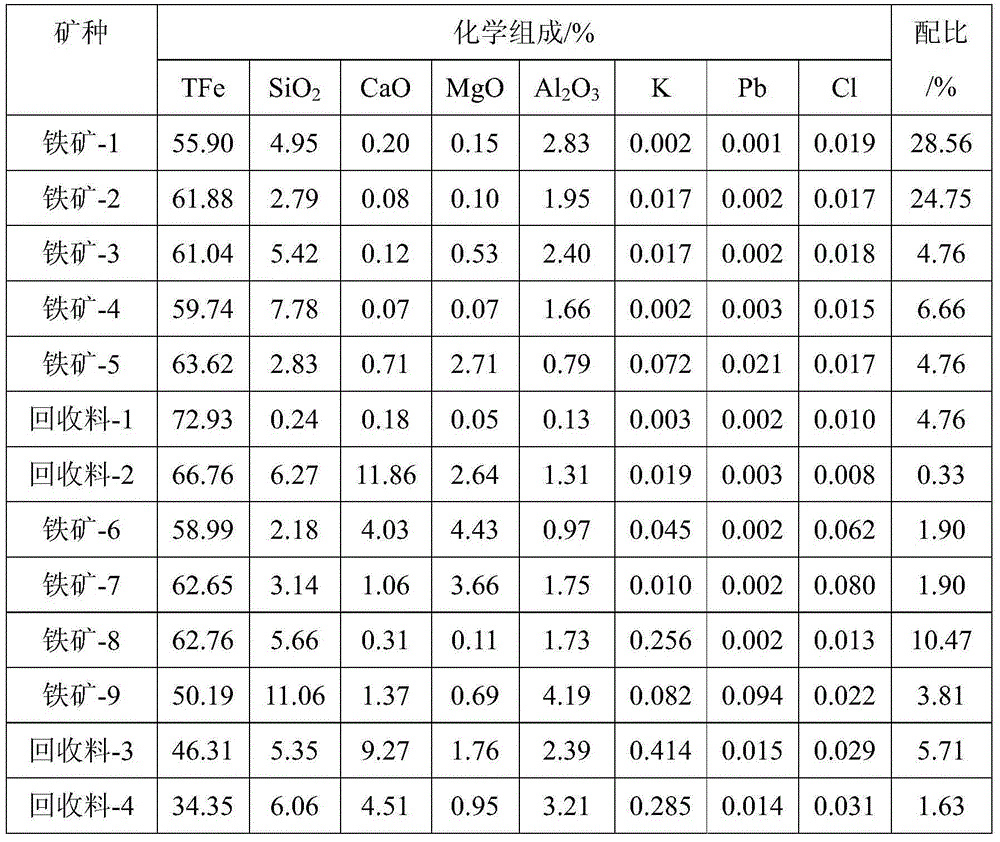

[0030] According to the characteristics of K, Pb, and Cl components in iron-containing raw materials, in Table 1, iron ore-1, iron ore-2, iron ore-3, iron ore-4, iron ore 5, recycled materials-1, recycled materials- 2 is iron-containing raw material with low content of harmful elements, iron ore-6 and iron ore-7 are high-chlorine iron-containing raw materials, iron ore-8, recycled material-3, and recycled material-4 are high-alkali iron-containing raw materials, Mine-9 is a high-lead iron-containing raw material. Iron ore-8, iron ore-9, recycled materials-3, recycled materials-4, quicklime (controlling alkalinity to 2.0) and fuel with a mass fraction of 4% were pre-granulated in a drum mixer for 3 minutes, and then The obtained granulated pellets are mixed with iron ore-6, iron ore-7, iron ore-1, iron ore-2, iron ore-3, iron ore-4, iron ore 5 and recycled material-1, recycled material-2 , return ore, remaining flux and fuel, and kaolin accounting for 2% of the total mass of iro...

Embodiment 2

[0032] According to the characteristics of K, Pb, and Cl components in iron-containing raw materials, in Table 1, iron ore-1, iron ore-2, iron ore-3, iron ore-4, iron ore 5, recycled materials-1, recycled materials- 2 is iron-containing raw material with low content of harmful elements, iron ore-6 and iron ore-7 are high-chlorine iron-containing raw materials, iron ore-8, recycled material-3, and recycled material-4 are high-alkali iron-containing raw materials, Mine-9 is a high-lead iron-containing raw material. Iron ore-8, iron ore-9, recycled materials-3, recycled materials-4, quicklime (controlling alkalinity to 2.2) and fuel with a mass fraction of 3% were pre-granulated in a drum mixer for 4 minutes, and then The obtained granulated pellets are mixed with iron ore-6, iron ore-7, iron ore-1, iron ore-2, iron ore-3, iron ore-4, iron ore 5 and recycled material-1, recycled material-2 , returned ore, remaining flux and fuel, and kaolin that accounted for 3% of the total mas...

Embodiment 3

[0034] According to the characteristics of K, Pb, and Cl components in iron-containing raw materials, in Table 1, iron ore-1, iron ore-2, iron ore-3, iron ore-4, iron ore 5, recycled materials-1, recycled materials- 2 is iron-containing raw material with low content of harmful elements, iron ore-6 and iron ore-7 are high-chlorine iron-containing raw materials, iron ore-8, recycled material-3, and recycled material-4 are high-alkali iron-containing raw materials, Mine-9 is a high-lead iron-containing raw material. Iron ore-8, iron ore-9, reclaimed material-3, reclaimed material-4, quicklime (controlling alkalinity to 2.4) and fuel with a mass fraction of 2% were pre-granulated once in a drum mixer for 5 minutes, and then The obtained granulated pellets are mixed with iron ore-6, iron ore-7, iron ore-1, iron ore-2, iron ore-3, iron ore-4, iron ore 5 and recycled material-1, recycled material-2 , returned ore, remaining flux and fuel, and kaolin that accounted for 4% of the tota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com