Komagataeibacter nataicola and application thereof

A single colony technology of Gluconacetobacter, which is applied in the field of microbiology, can solve the problems of few reported strains, and achieve significant economic benefits, simple and easy separation and screening methods, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

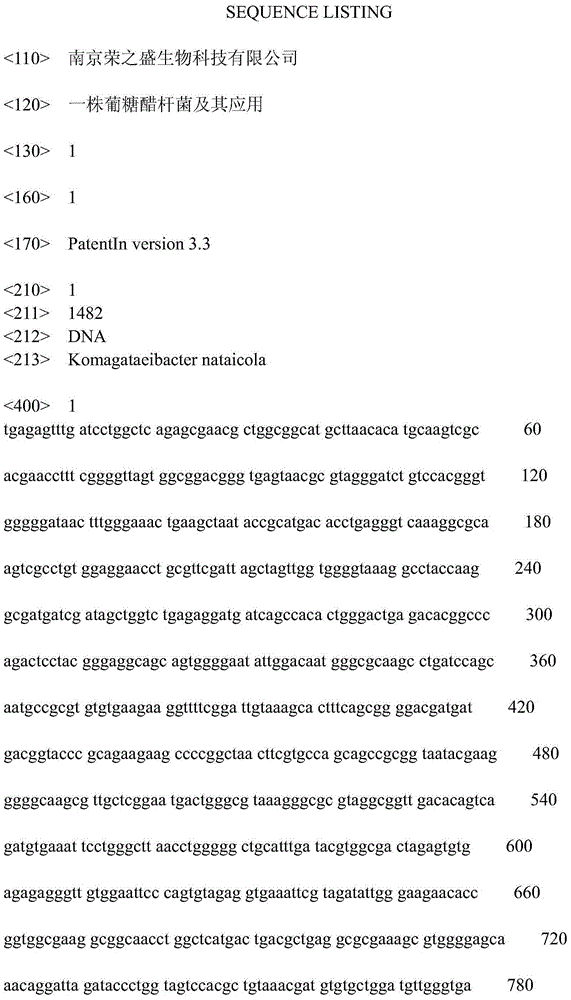

Image

Examples

Embodiment 1

[0026] This embodiment relates to the isolation and screening of bacterial cellulose production strain - Gluconacetobacter RZS01, the strain is isolated from defective fruit, the specific steps are as follows:

[0027] After the defective fruit is crushed, immerse and shake it with sterile water for 20 minutes to make a 10-fold dilution, then draw the dilution, and transfer it into the enrichment culture medium at a volume ratio of 1:10 between the dilution solution and the enrichment medium. In a base test tube, it was cultured statically at 30°C for 7 days, and the liquid surface in the tube was selected to have a milky white bacterial cellulose film, and 1 g of the bacterial cellulose film was taken out by an aseptic method, ground in a sterile mortar, and then added to 9 mL of sterile normal saline to prepare into 10 -1 Bacterial suspension, then diluted step by step, spread on the separation plate medium, cultured at 30°C for 5 days, picked a single colony with good growt...

Embodiment 2

[0032] Production of bacterial cellulose by static culture:

[0033] Inoculate the strains into the seed medium first, shake and culture at 25°C for 12 hours, rotate at 100rpm, insert 2% of the inoculum into the fermentation medium, and culture at a constant temperature of 30°C for 2 days, then take out the bacterial cellulose membrane. After purification and weighing after drying, the yield of bacterial cellulose obtained was 3.56g / L.

[0034] Fermentation medium: glucose 22g / L, sucrose 12g / L, peptone 16g / L, disodium hydrogen phosphate 3.5g / L, potassium dihydrogen phosphate 1g / L, magnesium sulfate 0.25g / L, acetic acid 2.4g / L, pH4 .2.

Embodiment 3

[0036] Production of bacterial cellulose by static culture:

[0037] First inoculate the strains into the seed medium, shake and culture at 35°C for 48 hours, with a rotation speed of 250rpm, insert 20% of the inoculum into the fermentation medium, culture at a constant temperature of 30°C for 10 days, and take out the bacterial cellulose membrane. After purification and weighing after drying, the yield of bacterial cellulose obtained was 3.42g / L.

[0038] Fermentation medium: fructose 25g / L, yeast extract powder 16g / L, sodium dihydrogen phosphate 2.9g / L, potassium dihydrogen phosphate 1g / L, magnesium sulfate 0.25g / L, citric acid 0.4g / L, pH6.5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com