Preparation method for corrosion resistance water-based paint with activated carbon as raw material

A water-based coating and activated carbon technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of single application method and limit the application of activated carbon, and achieve the effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

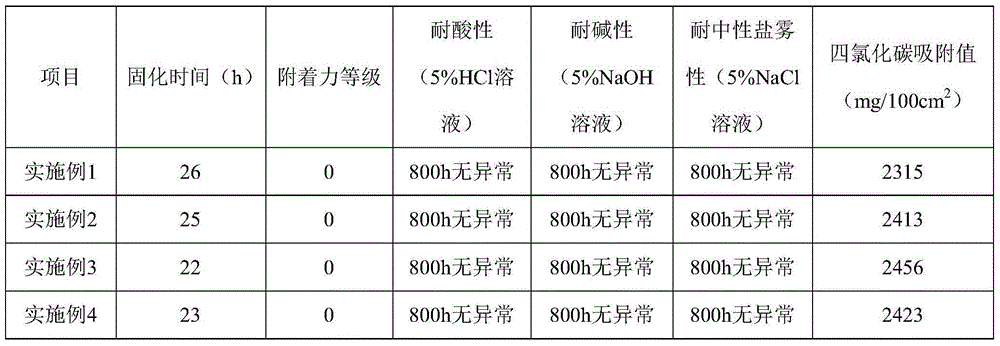

Examples

Embodiment 1

[0016] A kind of preparation method of the anticorrosion water-based paint that takes active carbon as base material, the steps are as follows:

[0017] Step 1, immersing 60 parts of activated carbon in parts by weight in a hydrochloric acid solution with a mass concentration of 5%, keeping it for 100 minutes, filtering and drying at a drying temperature of 180°C to obtain material 1;

[0018] Step 2: Add material 1 into the reaction kettle, add 20 parts of ammonium carbonate solution with a mass concentration of 20% in parts by weight, heat to 60°C, stir for 40 minutes, filter, and dry the filtered solid , the drying temperature is 100°C, and the material 2 is obtained;

[0019] Step 3: Add 50 parts of materials in parts by weight, 5 parts of n-butyl titanate, 0.8 parts of di-n-butyltin dilaurate, 3 parts of polyester fiber, and 2 parts of tetraethyl orthosilicate into the reaction kettle , heated up to 60°C under a vacuum condition of 0.01MPa, stirred for 30 minutes, then a...

Embodiment 2

[0021] A kind of preparation method of the anticorrosion water-based paint that takes active carbon as base material, the steps are as follows:

[0022] Step 1, immersing 65 parts of activated carbon in parts by weight in a hydrochloric acid solution with a mass concentration of 7%, keeping it for 105 minutes, filtering and drying at a drying temperature of 186°C to obtain material 1;

[0023] Step 2: Add material 1 to the reaction kettle, add 25 parts of ammonium carbonate solution with a mass concentration of 23% in parts by weight, heat to 64°C, stir for 48 minutes, filter, and dry the filtered solid , the drying temperature is 105°C, and the material 2 is obtained;

[0024] Step 3: Add 55 parts of material 2 in parts by weight, 7 parts of n-butyl titanate, 1 part of di-n-butyltin dilaurate, 4 parts of polyester fiber, and 4 parts of tetraethyl orthosilicate into the reaction kettle , heated up to 63°C under a vacuum condition of 0.02MPa, stirred for 35 minutes, then added...

Embodiment 3

[0026] A kind of preparation method of the anticorrosion water-based paint that takes active carbon as base material, the steps are as follows:

[0027] Step 1, immersing 70 parts by weight of activated carbon in a hydrochloric acid solution with a mass concentration of 8%, keeping it for 110 minutes, filtering and drying at a drying temperature of 190°C, to obtain material 1;

[0028] Step 2: Add material 1 into the reaction kettle, add 26 parts of ammonium carbonate solution with a mass concentration of 28% in parts by weight, heat to 67°C, stir for 55 minutes, filter, and dry the filtered solid , the drying temperature is 115°C, and the material 2 is obtained;

[0029] Step 3: Add 57 parts by weight of material 2, 8 parts of n-butyl titanate, 1.5 parts of di-n-butyltin dilaurate, 5 parts of polyester fiber, and 5 parts of tetraethyl orthosilicate into the reaction kettle , heated up to 66°C under a vacuum condition of 0.03MPa, stirred for 40 minutes, then added 5 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com