Functional steel slag powder

A steel slag powder and functional technology, which is applied in the field of comprehensive utilization of solid waste, can solve the problems of low early activity and restrict the popularization and application of steel slag powder, and achieve the effects of improving performance, reducing production costs and saving land resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

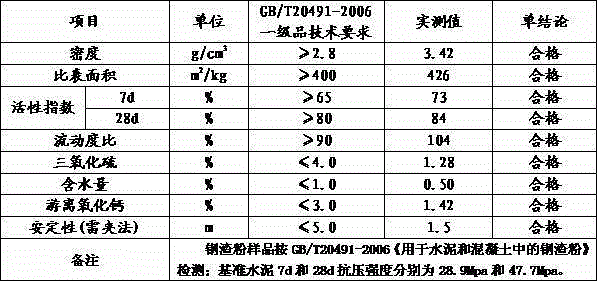

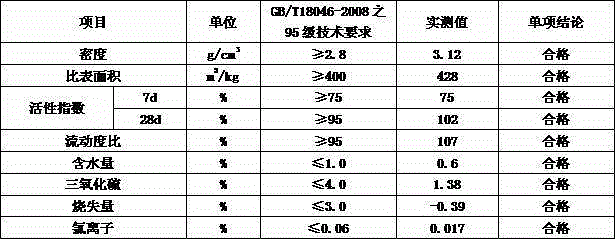

Embodiment 1

[0022] Compound 35% functional steel slag powder and 65% granulated blast furnace slag powder, and test according to GB / T18046-2008 "Granulated Blast Furnace Slag Powder Used in Cement and Concrete". The performance indicators are shown in Table 2 As shown (compressive strength of benchmark cement 7d and 28d are 36.7Mpa and 48.0Mpa respectively; specific surface area of granulated blast furnace slag powder used is 373m 2 / kg, 7d and 28d strength indices are 77% and 111% respectively, fluidity ratio is 106%);

[0023] Table 2 Comparison of the actual measurement index of functional steel slag powder and granulated blast furnace slag powder with GB / T18046-2008

[0024]

Embodiment 2

[0026] Compound 34% functional steel slag powder, 33% granulated blast furnace slag powder and 33% fly ash, and test according to GB / T18046-2008 "Granulated Blast Furnace Slag Powder Used in Cement and Concrete" , and its performance indicators are shown in Table 3 (compressive strengths of benchmark cement 7d and 28d are 36.7Mpa and 48.0Mpa respectively; the specific surface area of granulated blast furnace slag powder used is 373m 2 / kg, 7d and 28d strength indices are 77% and 111% respectively, fluidity ratio is 106%);

[0027] Table 3 Comparison of the measured indicators of functional steel slag powder, slag powder and fly ash composite powder with GB / T18046-2008

[0028]

[0029] In the present invention, steel slag powder with a weight ratio of about 35% and granulated blast furnace slag powder or fly ash with a weight ratio of about 65% can be added into the concrete to form a composite system for double-mixing or triple-mixing, and the steel slag powder can be un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com