A multi-group double-drop double-molding rotary matrix machine

A technology of rotary and row machines, applied in glass forming, glass blowing, glass manufacturing equipment, etc., can solve the problems of single application range, inconvenient use, difficult maintenance, etc., and achieve compact structure of the whole machine and a blanking position The effect of accuracy and low equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

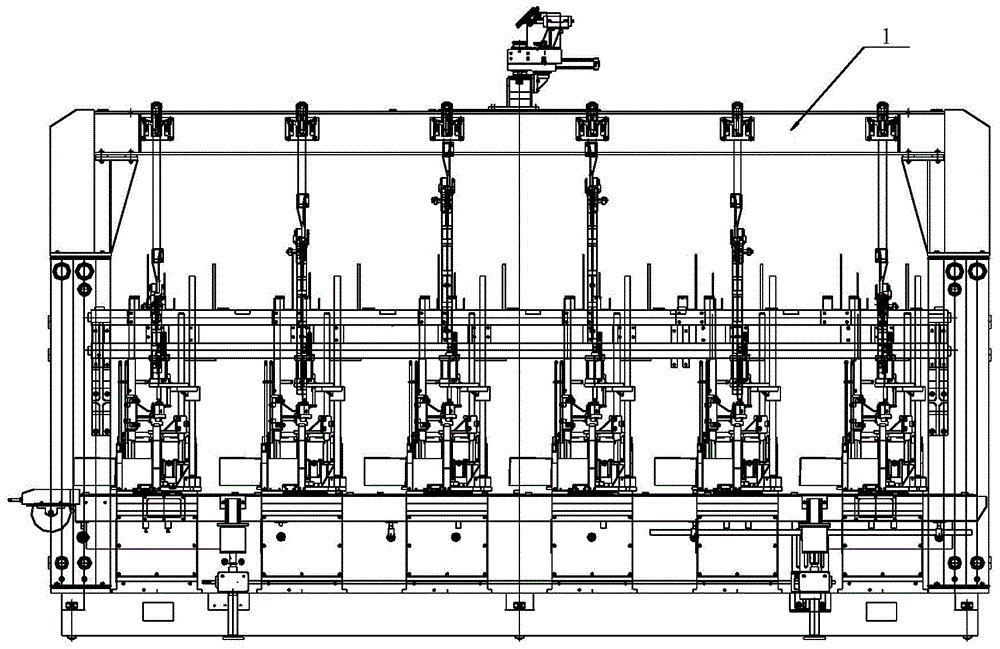

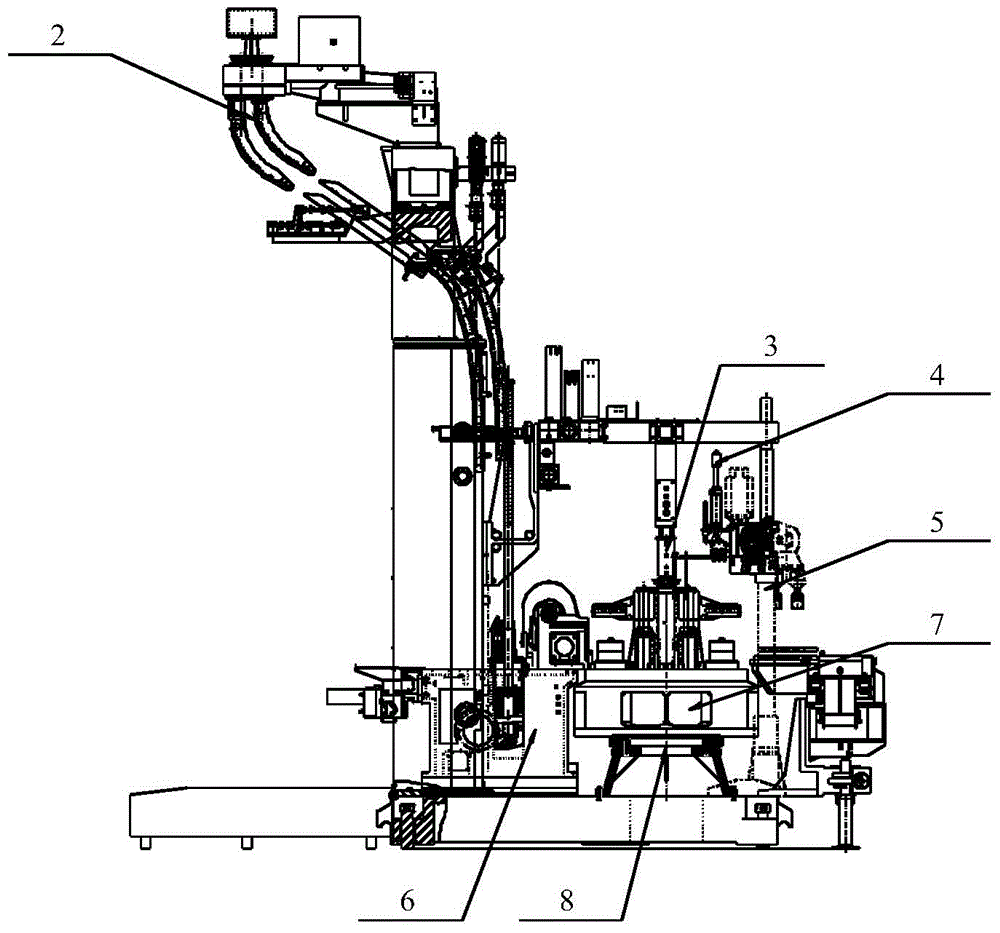

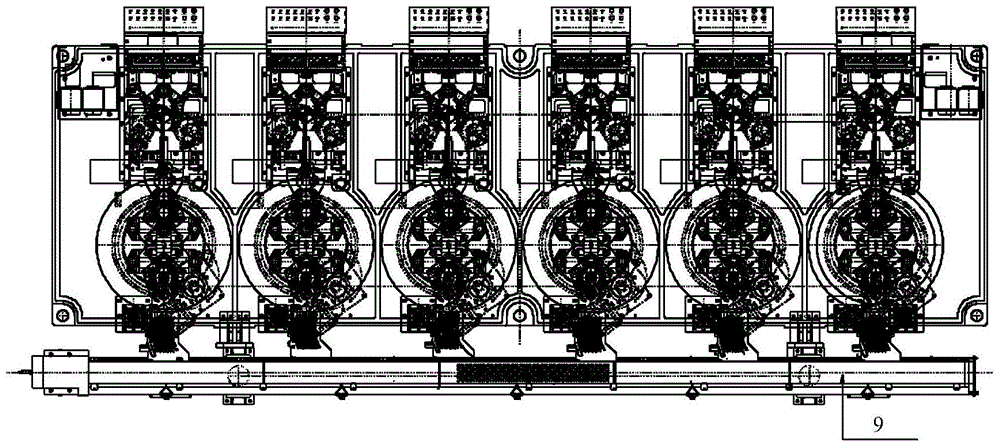

[0060] see figure 1 As shown, multiple groups of double-drop double-molding rotary row machines in the embodiment of the present invention include a main frame 1; see figure 2 As shown, the main frame 1 is provided with 2 to 10 sets of servo turntable mechanisms 8, and the top of the servo turntable mechanisms 8 is provided with a composition-type side upper turntable mechanism 7, and the top of each composition-type side upper turntable mechanism 7 is provided with an oil-air slip ring Component 3. see figure 2 and image 3 As shown, the main frame 1 is also equipped with a double drip system 2, an electronic bottle shifting conveyor belt 9, 2 to 10 sets of rotating bottle holding mechanisms 4, 2 to 10 sets of servo bottle clamp mechanisms 5 and 2 to 10 sets of prototypes Side box assembly 6.

[0061] The servo turntable mechanism 8, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com