Cyclonic anaerobic reaction apparatus, AMBR sewage treatment system and sewage treatment method

A technology of anaerobic reaction device and sewage treatment system, applied in anaerobic digestion treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Problems such as uneven distribution of oxygen sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

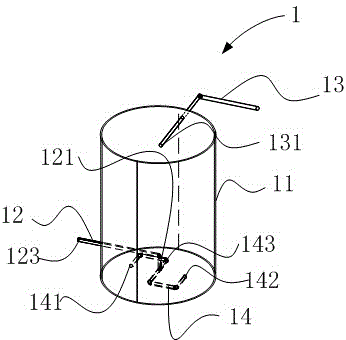

[0025] Please also refer to figure 1 , The cyclone anaerobic reaction device 1 provided by the embodiment of the present invention is characterized in that it includes a sealed reactor shell 11, an inlet pipe 12, an outlet pipe 13, and is located in the reactor shell 11 and arranged parallel to the reactor shell. The distribution pipeline 14 at the bottom of the body 11, the distribution pipeline 14 at least includes a pair of first water outlet 141 and the second water outlet 142 arranged in opposite directions, the distribution pipeline 14 is also provided with an outlet pipe connection port 143, and the water inlet pipe 12 passes through the reaction The side wall of the reactor housing 11 and the water outlet 121 of the water inlet pipe 12 are connected with the water outlet connection port 143 of the shunt pipe 14, the water outlet pipe 13 passes through the side wall of the reactor housing 11 and the water inlet 131 of the water outlet pipe 13 is located in the reactor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com