Microchannel reactor

A technology of microchannel reactor and circulation channel, which is applied in the field of microreaction, can solve the problems of difficult application of industrial production, small reaction material flow rate, difficult application, etc., to improve the degree of reaction adequacy, increase the reaction flow path, and facilitate disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

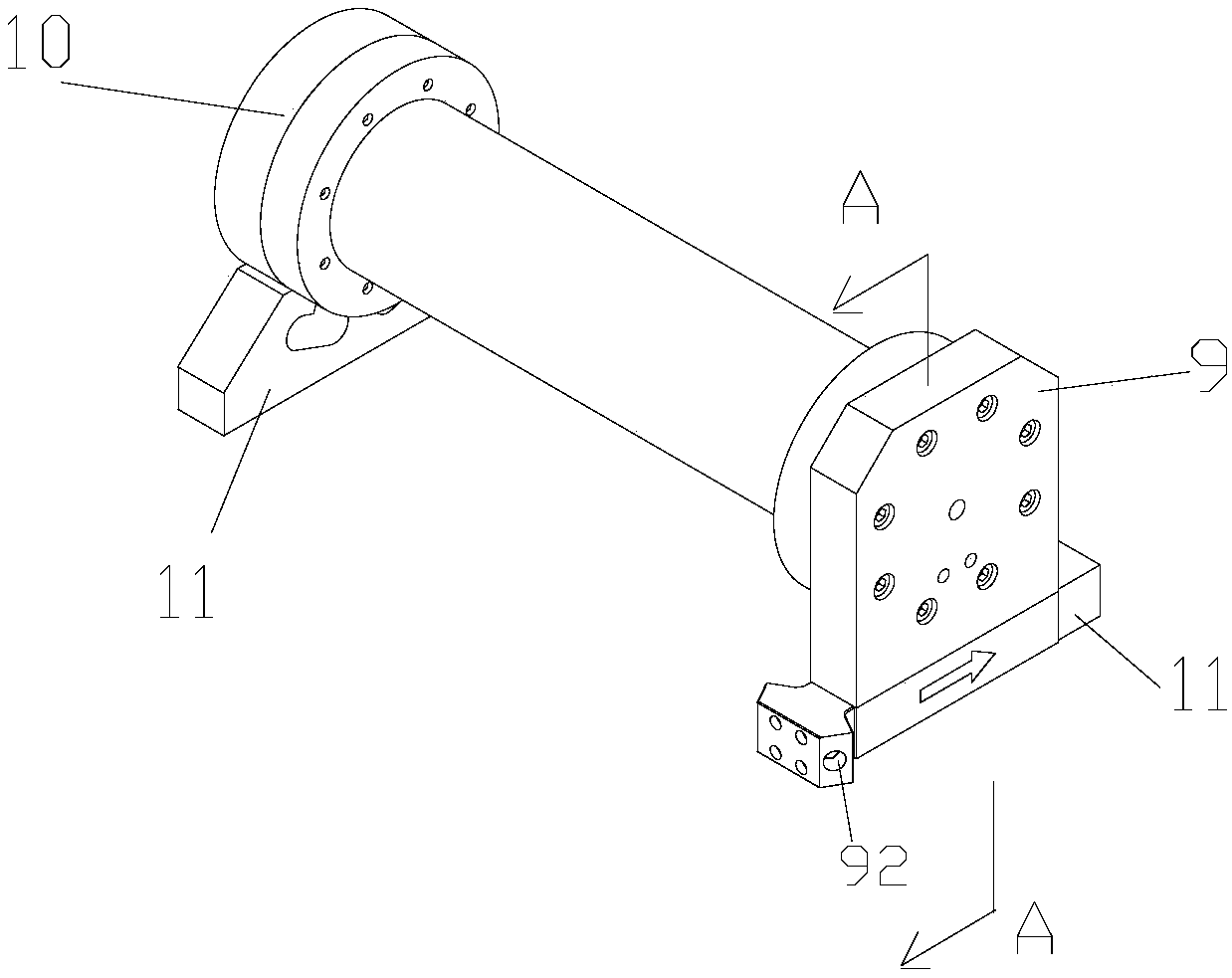

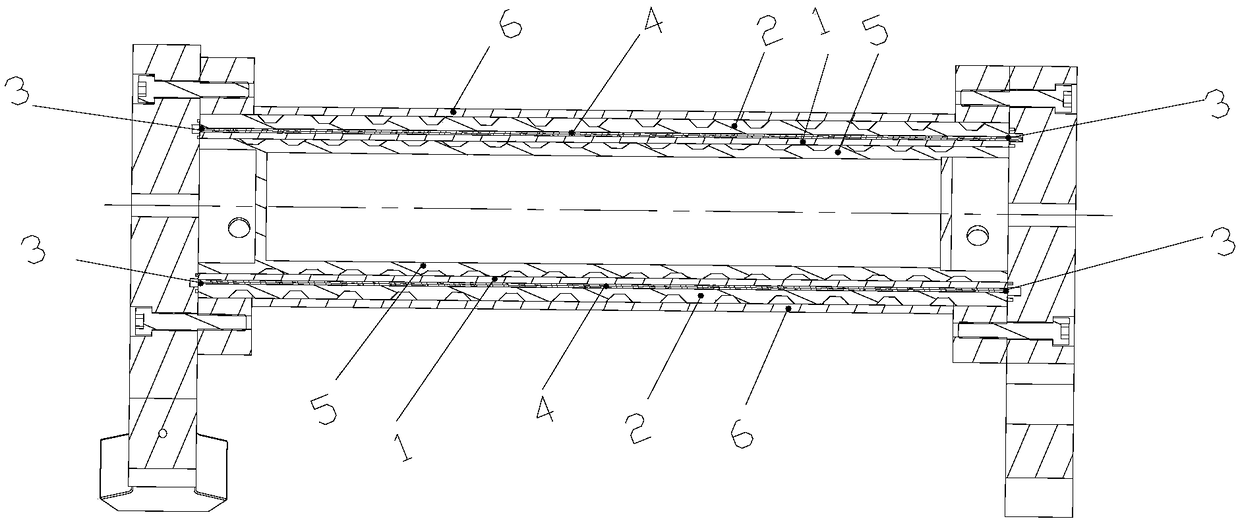

[0062] like Figure 1-15b Shown, the invention provides a kind of microchannel reactor, it comprises:

[0063] The inner sleeve 1 and the outer sleeve 2, the outer sleeve 2 is sleeved on the outer periphery of the inner sleeve 1, and a receiving groove is arranged on the outer wall of the inner sleeve 1 and / or the inner wall of the outer sleeve 2 3;

[0064] The microchannel reactor also includes an insert structure 4 that can be inserted in the accommodation groove 3, and the inner sleeve 1 and the outer sleeve 2, the accommodation groove 3 and the insert structure 4 are in common defining a flow channel for the reaction fluid to flow;

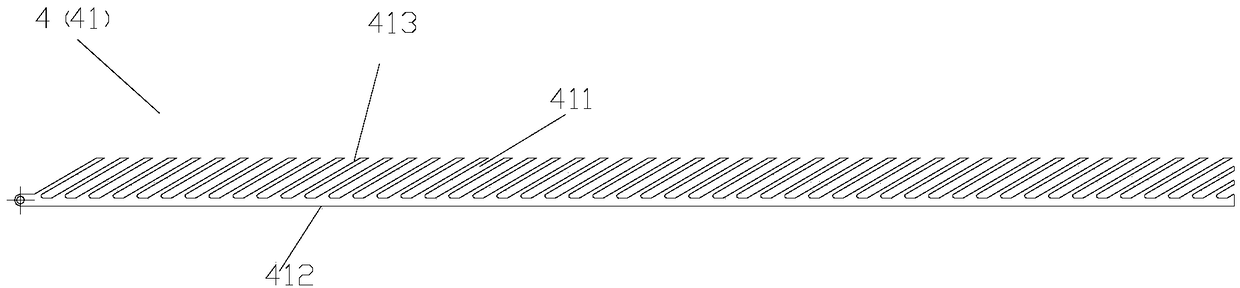

[0065] The insert structure 4 includes a first insert 41 and a second insert 42 that are stacked (the insert can be two or more than two sheets stacked, and the insert can be a flat sheet or an arc sheet) , and the first insert 41 includes a first flow groove 411 opened along the first extending direction, and the second insert 42 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com