Vibration enhanced heat transfer device for automobile radiator

An automotive radiator and heat transfer enhancement technology, which is applied in the power plant, the arrangement of the cooling combination of the power plant, vehicle components, etc. problem, to achieve the effect of enhancing heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

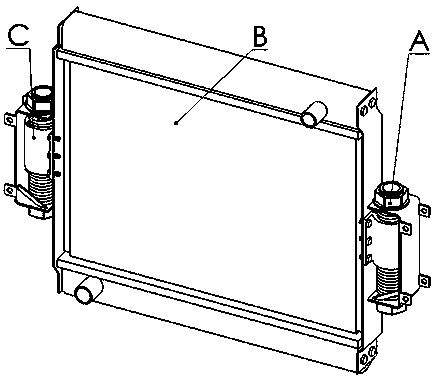

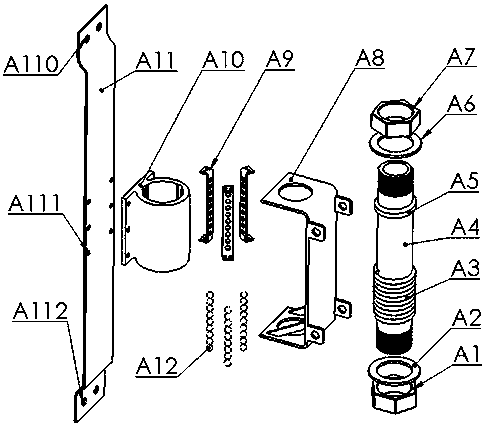

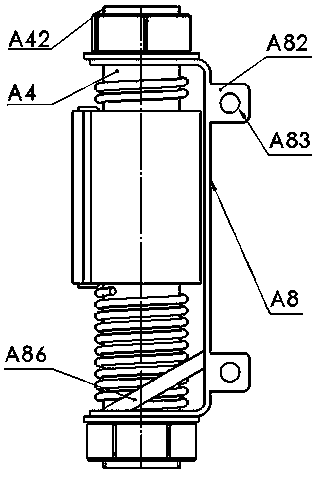

[0036] refer to Figure 1 to Figure 7 As shown, a kind of automobile radiator vibration strengthening heat transfer device provided by the present invention comprises a radiator B, a left elastic vibrator C and a right elastic vibrator A are respectively installed at two ends of the radiator B, and a left elastic vibrator C and a right elastic vibrator are installed respectively. The elastic vibrator A has the same structure, and both include a side plate A11 connected to the radiator B. A bearing seat A10 is installed on the side plate A11, and a guide shaft A4 is pierced in the bearing seat A10, and the guide shaft A4 at the upper end of the bearing seat A10 is also After passing through the upper wing edge A81 of the bracket A8, it is connected with the upper limit device. The guide shaft A4 at the lower end of the bearing seat A10 also passes through the lower wing edge A84 of the bracket A8 and is connected with the lower limit device. The bearing seat A10 is connected wit...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is that, refer to Figure 13 As shown, the depth of the arc raceway A100 is greater than the radius of the ball A12, and the diameter of the isolation hole A91 is smaller than the diameter of the ball A12, thereby confining the ball A12 in the arc raceway A100. The isolation hole A91 is a round hole, which is less difficult to process than the tapered hole in Embodiment 1. At the same time, the contact surface between the ball A12 and the arc raceway A100 is large, and the bearing capacity is improved, which is suitable for the case where the diameter of the ball A12 is large.

[0045] refer to Figure 14 As shown, the bearing seat A10 is connected with the side plate A11 through the connecting plate, and the side plates A11 on the left and right sides of the bearing seat A10 are provided with a plurality of first installation holes A102, and the side plates A11 at the upper and lower ends of the bearing seat A10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com