Production method of water delivery pipes

A technology for water delivery pipes and rubber seeds, which is applied in the field of water delivery pipe preparation, can solve the problems that the tensile strength is difficult to meet the requirements, the UV resistance performance is not good, and the water transportation cannot be satisfied, and the adhesion and tearing of the pipe body can be guaranteed. Strong, small deformation, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

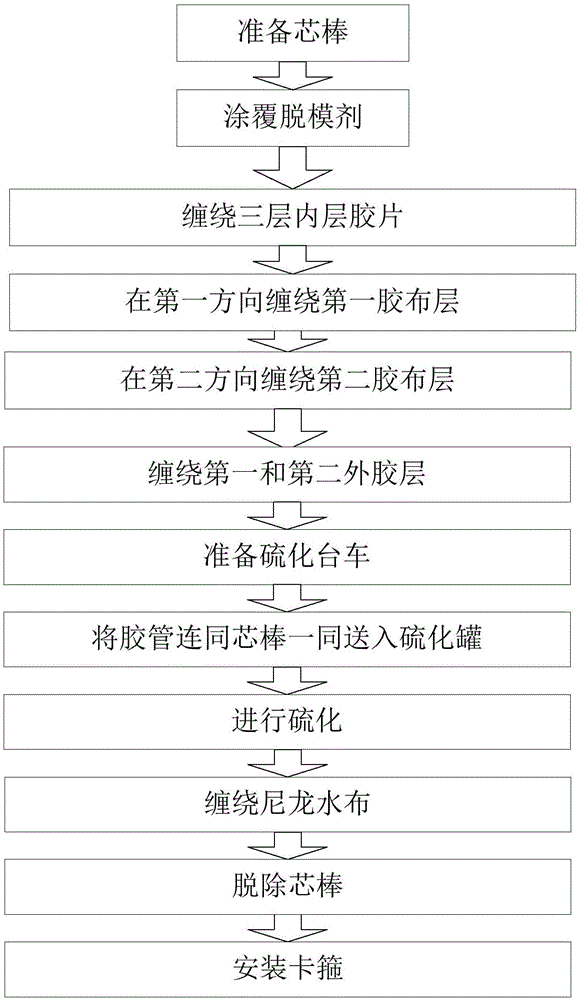

[0041] Combine below figure 1 The preparation method of the present invention is specifically described.

[0042] In this method, when preparing the water delivery pipe, at first the mandrel is prepared, and the mandrel is used for winding the rubber hose thereon. Before preparing the hose, the mandrel should be cleaned.

[0043] Then prepare the Le Ruigu 1524 release agent, stir the release agent evenly until it becomes a milky white liquid, and coat the prepared Le Ruigu 1524 release agent on the mandrel. The function of the release agent is to wait until the subsequent rubber hose is prepared and shaped, and the mandrel can be taken out of the rubber hose smoothly. Due to the multiple high-temperature processes involved in the preparation of the rubber hose, if no release agent is applied, the subsequent rubber hose will adhere to the mandrel after molding and cannot be taken out. In another implementation manner, peanut oil is used as the release agent.

[0044] Next, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com