Floatation method of sulfur-oxygen mixed lead antimony ore

A mixed ore, sulfur and oxygen technology, applied in flotation, solid separation, etc., can solve the problems of long production process, unstable production, difficult production control, etc., and achieve high recovery rate, simple process structure and high-grade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] An example of the flotation method of sulfur-oxygen mixed lead-antimony ore of the present invention comprises the steps:

[0016] 1. Mineral raw materials:

[0017] The mineral raw material used is lead-antimony-zinc-oxygen mixed ore, and the content of lead in the ore is 0.28%, antimony 0.24%, zinc 1.26%, and sulfur 5.63%. The phase analysis shows that the lead-antimony minerals are mainly brittle-stibnite, with a small amount of galena and stibnite; Mainly iron ore and pyrrhotite, with a small amount of arsenopyrite. The oxidation rate of lead in the ore reaches 24.27%, the oxidation rate of antimony reaches 28.10%, and the oxidation rate of zinc reaches 19.65%.

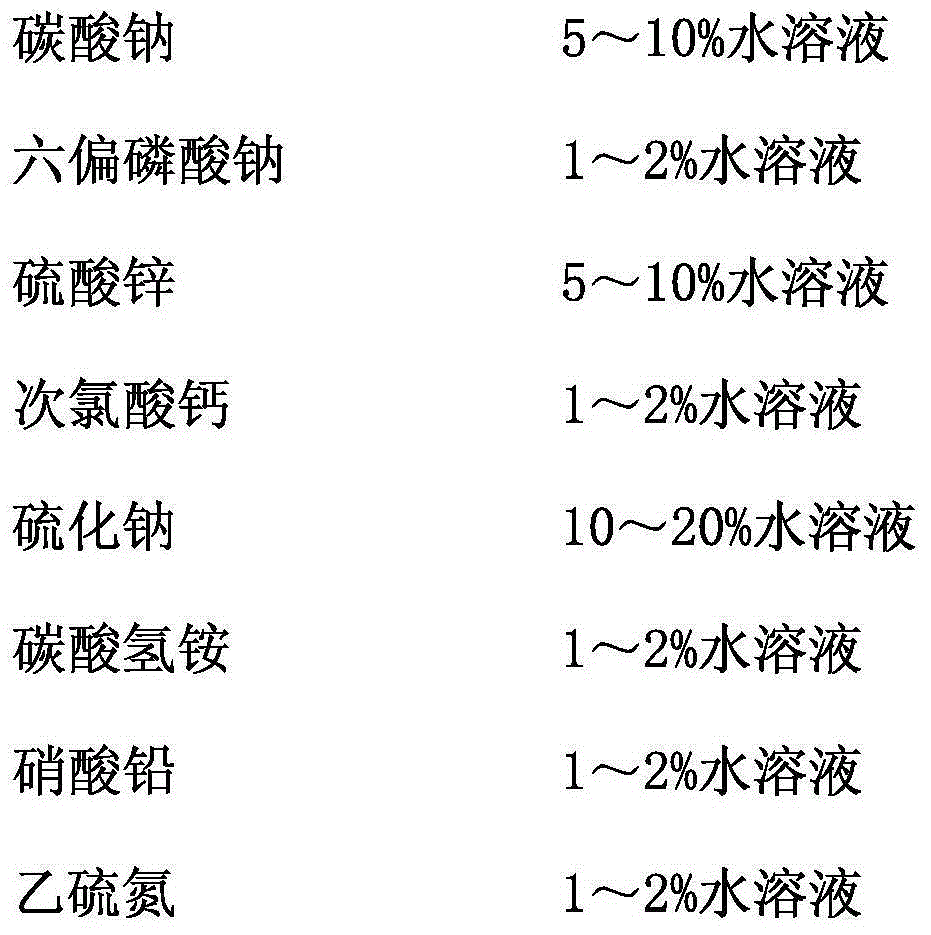

[0018] 2. Flotation agents and operating conditions:

[0019]

[0020]

[0021] During the flotation process, the ore is ground until the mineral monomers are dissociated, then sodium carbonate is added to adjust the pH to 7.5-8, sodium hexametaphosphate is used as a fine mud mineral dispersant, zi...

Embodiment 2

[0023] Another example of the flotation method of sulfur-oxygen mixed lead-antimony ore of the present invention comprises the steps:

[0024] 1. Mineral raw materials:

[0025] The mineral raw material used is lead-antimony-zinc-oxygen mixed ore, and the content of lead in the ore is 1.07%, antimony 0.83%, zinc 3.20%, and sulfur 7.36%. The phase analysis shows that the lead minerals are mainly galena and a small amount of white lead minerals, the antimony is mainly stibnite, the zinc minerals are mainly sphalerite and a small amount of sphalerite, and the sulfur minerals are mainly Mainly pyrite and arsenopyrite, with a small amount of pyrrhotite. The oxidation rate of lead in the ore reaches 30.50%, the oxidation rate of antimony reaches 33.52%, and the oxidation rate of zinc reaches 21.70%.

[0026] 2. Flotation agents and operating conditions:

[0027]

[0028] During the flotation process, the ore is ground until the mineral monomers are dissociated, then sodium car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com