Catalyst system and method for simultaneous desulfurization and denitrification by ammonia process

A technology of desulfurization, denitrification, and catalyst, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of exhaust gas treatment that is difficult to meet emission standards, slow absorption speed, secondary pollution, etc., and achieve catalyst consumption. Effects of recycling, mild absorption conditions, and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment relates to a group of catalyst systems of metal phthalocyanine compounds and water-insoluble organosilicon, and the components of each catalyst system are shown in the following table:

[0033]

[0034] Mix the metal phthalocyanine compound and water-insoluble organic silicon according to the ratio mentioned in the above table, and the metal phthalocyanine compound is suspended and dispersed in the water-insoluble organic silicon, which is used as a catalyst system for simultaneous desulfurization and denitrification in the ammonia method.

Embodiment 2

[0036] This embodiment relates to a method for simultaneous desulfurization and denitration by ammonia method.

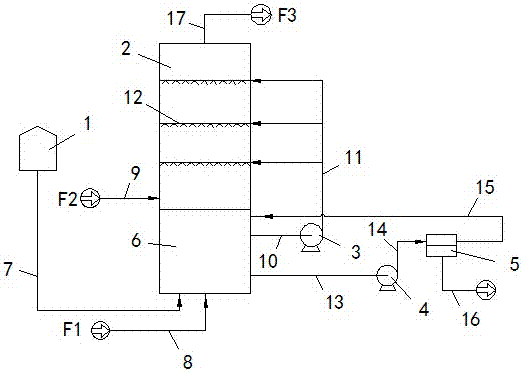

[0037] The ammonia method of the present embodiment simultaneously desulfurizes and denitrates the method, adopts the equipment such as figure 1As shown, the lower part of the desulfurization and denitrification tower 2 is the reaction chamber 6, the bottom of the reaction chamber 6 is provided with an ammonia water supply pipe 7 and an oxygen supply pipe 8, and the ammonia water supply pipe 7 is connected with the ammonia water storage tank 1 for feeding the reaction chamber Ammonia water is supplied in 6; oxygen supply pipe 8 is used to supply oxygen F1 into the reaction chamber 6; a flue gas input pipe 9 is provided in the middle of the desulfurization and denitrification tower 2, and is used to feed flue gas F2 into the reaction chamber 6 The upper part of the reaction chamber 6 is provided with an output pipe 10, which is connected with the circulation pump 3, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com