Vacuum defoaming device

A technology of vacuum defoaming and vacuum pump, applied in the direction of foam dispersion/prevention, etc., can solve the problems of difficult discharge of air bubbles, high resin viscosity, high surface tension, etc., to improve product surface quality, ensure vacuum sealing effect, and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] With reference to the accompanying drawings, the specific implementation of the present invention will be further described in detail through the description of the best embodiment.

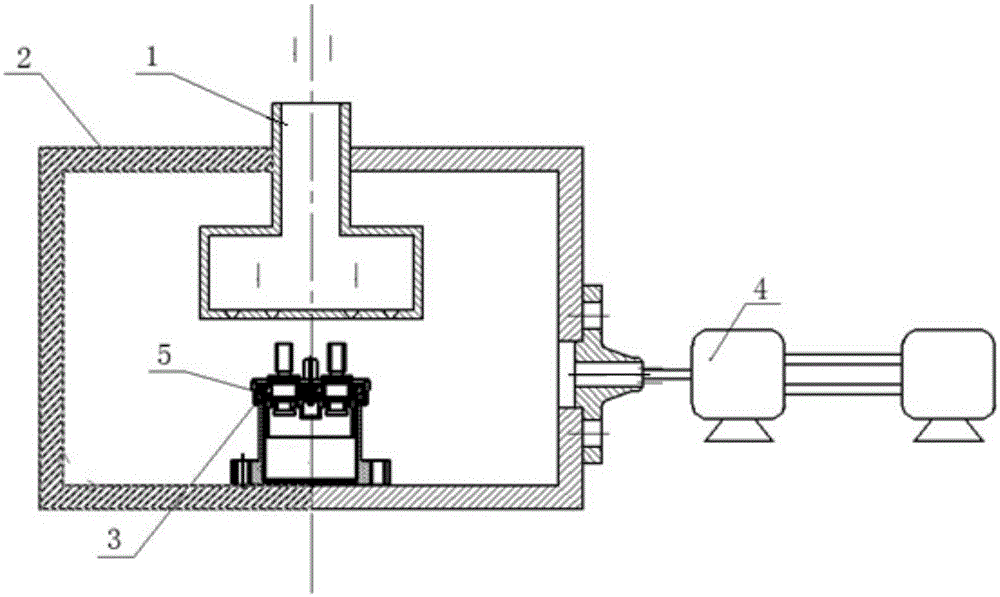

[0018] Such as figure 1 As shown, the vacuum degassing device includes a vacuum chamber 2 for placing a workpiece 3, and the vacuum chamber 2 is connected with a vacuum pump 4 and a high-pressure air injection nozzle 1. Turn on the vacuum pump 4 to vacuum. After the vacuum in the vacuum chamber 2 reaches the closed set value or the vacuum pump 4 reaches the set time, turn off the vacuum pump 4; open the high-pressure air injection nozzle 1, and the high-pressure air quickly enters the vacuum chamber 2. The bubble on the surface of the workpiece 3 bursts due to the rapid change of the internal and external pressure difference. At the same time, the pressure of the rapidly injected high-pressure gas acts on the surface of the bubble so that the bubble is blown; this way repeated two to four cyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com