Flat plate inclination measurement device based on multi-point off-focus detection

A technology of tilt measurement and flat panel, which is applied in the direction of measuring device, measuring tilt, surveying and navigation, etc., can solve the problems of limited detection range, limitation, adjustment lag, etc., and achieve the improvement of practicality, fast and timely adjustment process, and simplified structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

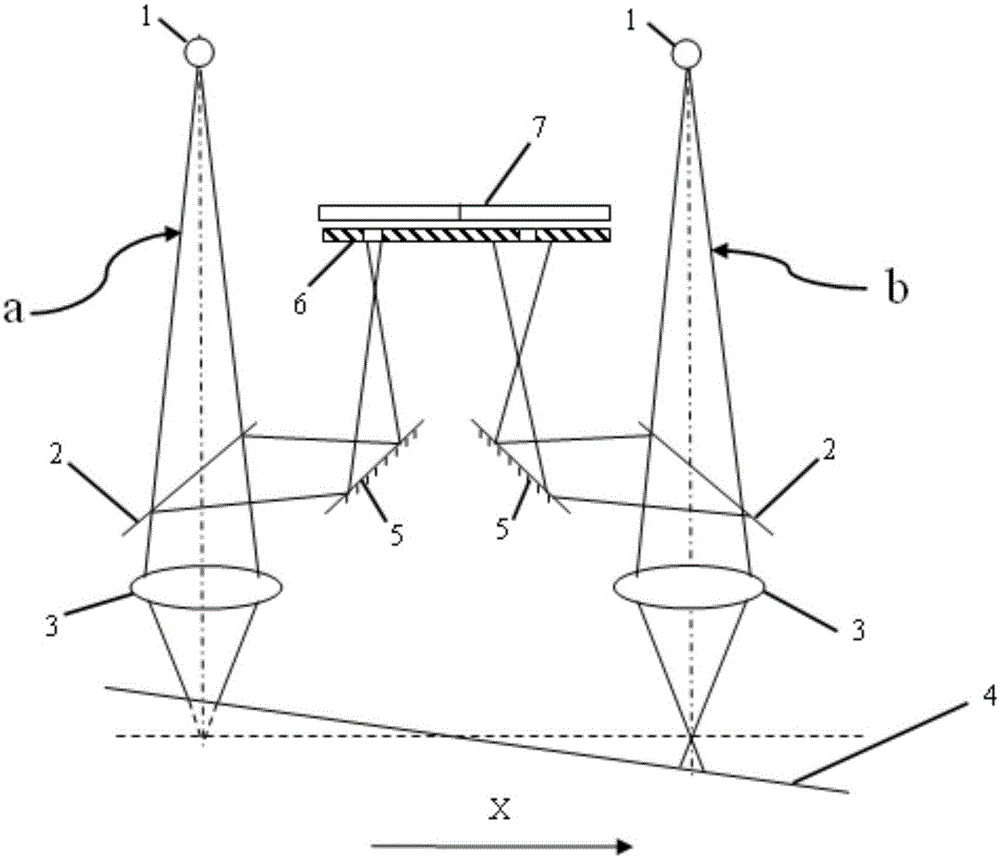

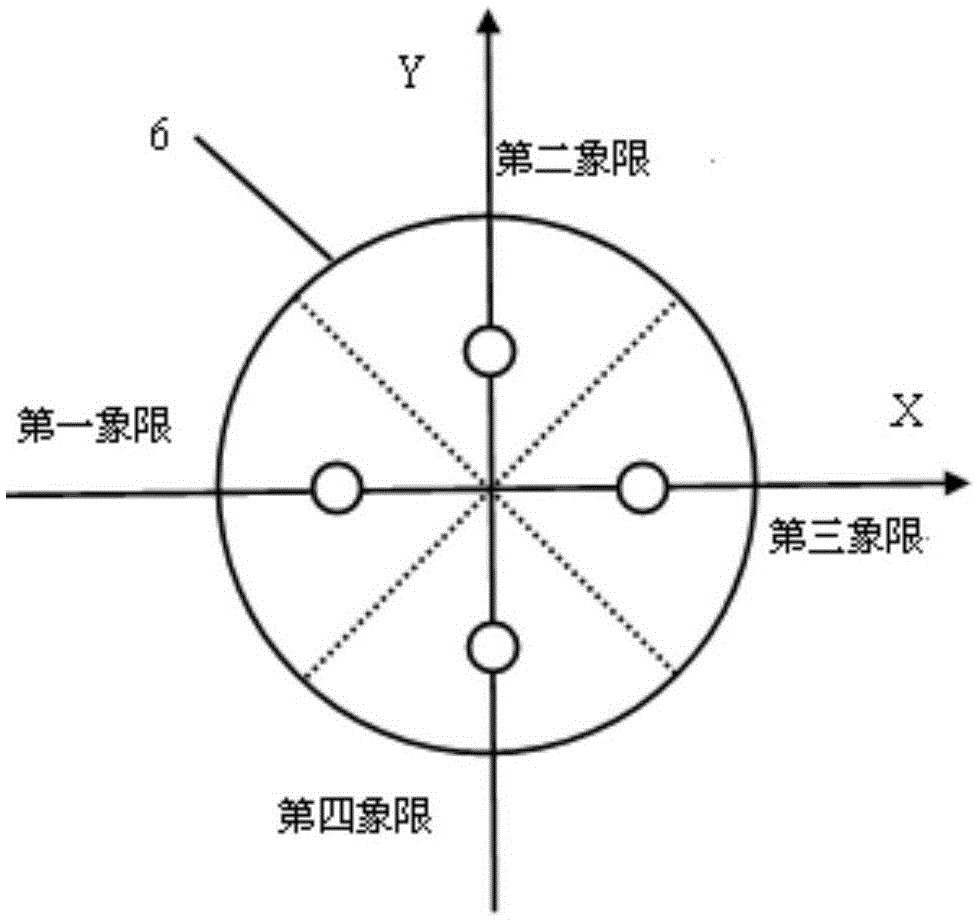

[0026] see figure 1 In the present embodiment, the detection optical path is set as follows: a point light source 1 is used as an illumination light source, and the point light source 1 is irradiated on the point to be measured of the flat plate 4 through the half mirror 2 and the objective lens 3, and the The surface of the point to be measured on the measuring plate 4 forms reflected light; the reflected light is reflected to the half-mirror 2 through the objective lens 3, and in the half-mirror 2, beams are split at 5:5 to form an optical axis A first light beam and a second light beam that are 90° to each other; the second light beam passes through the mirror 5 and passes through the pinhole in the pinhole plate 6 to project on the central position of a certain quadrant of the four-quadrant detector 7;

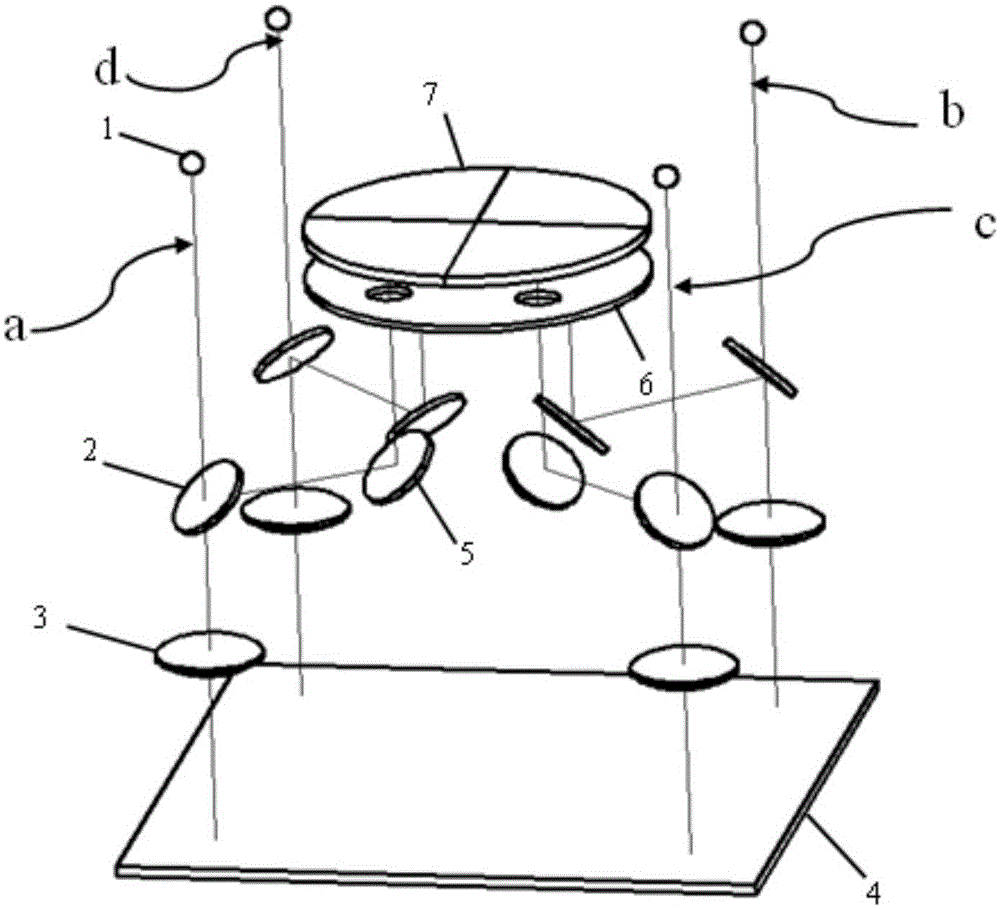

[0027] see figure 2 , image 3 and Figure 4 In this embodiment, the flat plate tilt measurement device based on multi-point defocus detection is provided with four de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com