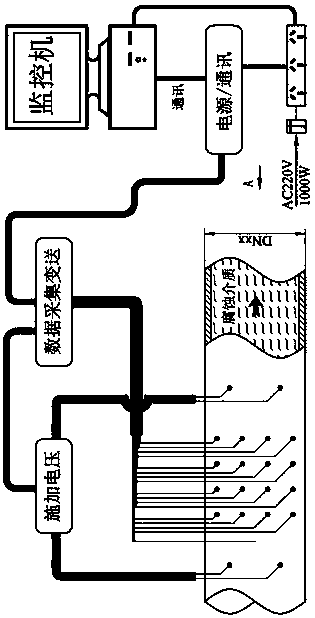

A crimping measuring electrode device in an electric field matrix thickness measuring system

A measuring electrode, crimping technology, used in electromagnetic measuring devices, electrical/magnetic thickness measurement, etc., can solve the problems of no installation conditions, installation is not allowed, the integrity of the tested pipeline is damaged, etc., to save resources, install Convenience, the effect of increasing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

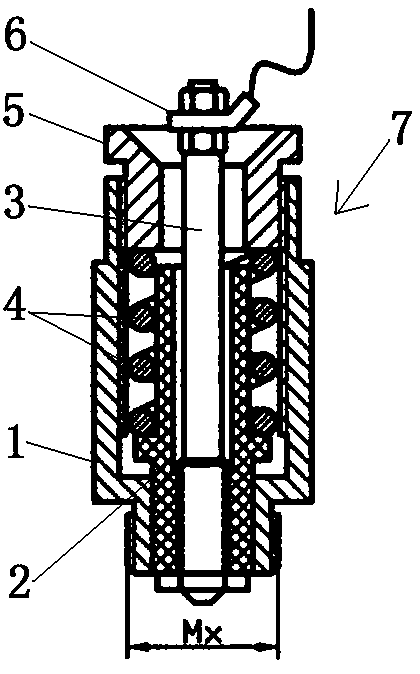

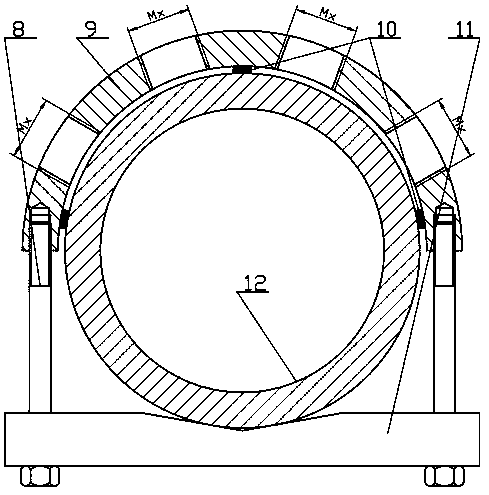

[0022] The present invention is further described in detail according to the accompanying drawings.

[0023] A crimping measuring electrode device in an electric field matrix thickness measuring system, comprising a plurality of insulating isolation terminals 7 and a mounting bracket, the plurality of insulating isolation terminals 7 have the same structure, and each insulating isolation terminal 7 is covered by a sliding sleeve 1 , a measurement terminal pen, a compression spring 4, and a spring compression cap 5. The measurement terminal pen includes a metal measurement electrode 3 and a sliding shaft 2. The sliding shaft 2 is provided with a through hole in the axial direction, and the metal measurement electrode 3 is assembled on the In the through hole of the sliding shaft 2, the outer surface of the metal measuring electrode 3 and the inner wall of the through hole of the sliding shaft 2 are fixedly connected into one body through an insulating layer to form a measuring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com