Ozone water electrolysis device directly connected to coated electrode

An ozone water, direct technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problem that corrosion resistance affects the energy consumption efficiency, working stability and service life of the electrolysis cell, and achieves that it is not easy to peel off the membrane and reduce energy consumption. Lowering, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

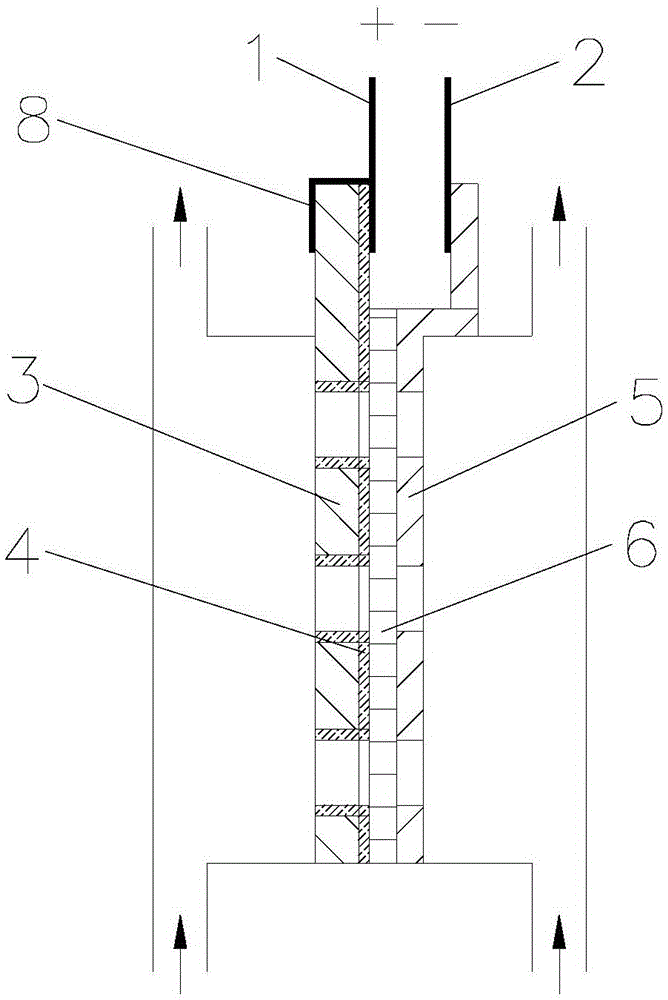

[0025] like figure 1 As shown, the present invention discloses a device for electrolyzing ozone water directly connected to a coating electrode, comprising an electrolytic tank, the electrolytic tank is provided with a cathode and an anode, and the cathode and anode respectively include a cathode base 5 and an anode base 3 , the anode is plated with a layer of conductive film 4 on its anode base 3, the conductive film 4 is directly connected to the anode terminal, and after the current flows in from the anode terminal, it directly flows through the conductive film to perform electrolysis in the electrolyzer, and the anode terminal The part connected to the conductive film is arranged outside the electrolytic cell; of course, in this embodiment, the same treatment method as the anode end can also be used on the cathode end.

[0026] like figure 1 As shown, in this embodiment, the anode terminal and the cathode terminal use elastic conductive clips 8, and at the anode end, the ...

Embodiment 2

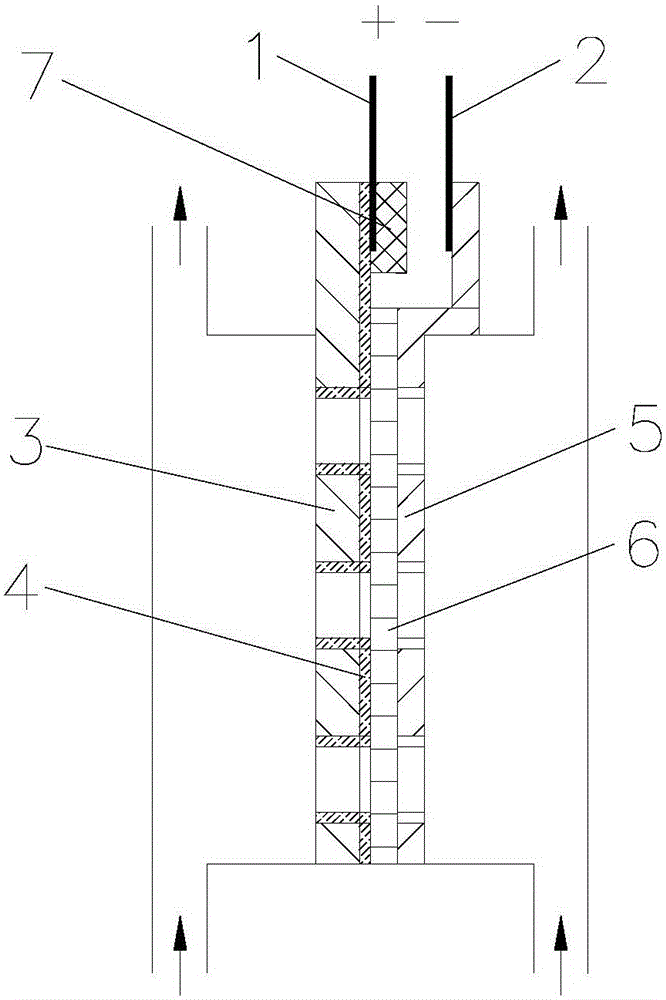

[0033] like figure 2 As shown, the present invention discloses a device for electrolyzing ozone water directly connected to a film-coated electrode. 3 are respectively plated with a layer of conductive film 4, the conductive film 4 is directly connected to the cathode terminal 2 and the anode terminal 1, the current flows in from the anode terminal 1 and directly flows through the conductive film 4 to perform electrolysis in the electrolytic cell, the anode terminal 1 and the part where the cathode terminal 2 is connected to the conductive film 4 are arranged outside the electrolytic cell.

[0034] like figure 2 As shown, the anode terminal 1 and the cathode terminal 2 are connected to the conductive film 4 through the coating electrode adhesive 7, as in Example 1, the current directly flows through the conductive film 4 from the anode terminal (or cathode terminal) to realize electrolysis , in this embodiment, since the conductive layer of the coating electrode is directl...

Embodiment 3

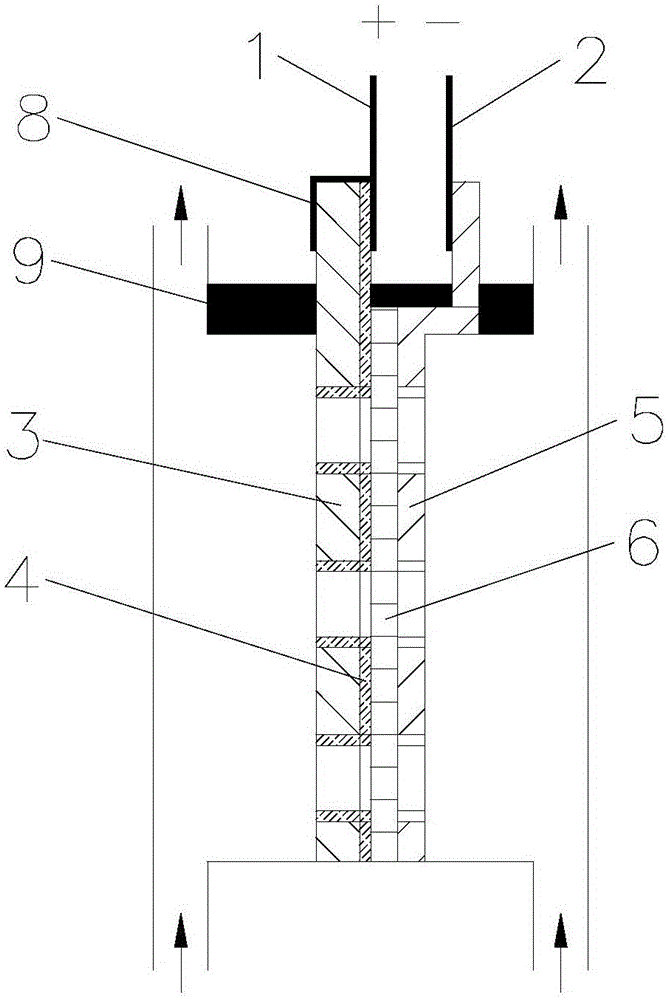

[0037] like image 3 As shown, the structure of this embodiment is the same as that of Embodiment 1 or Embodiment 2, and the main difference is that: the connection between the anode terminal 1 and the cathode terminal 2 and the conductive film 4 is encapsulated by the sealing material 9, thereby overcoming the problem of poor connection and contact. Partial new anodes and cathodes are formed in the gaps to form an oxidation reaction, and a new oxide layer is formed at the contact site, which makes it difficult for the current to pass through, and finally the connection site will be corroded. A proton exchange membrane 6 is provided between the cathode conductive film and the anode conductive film. Certainly, the electrolytic ozone water device in the present embodiment can also not be provided with proton exchange membrane, as Figure 4 As shown, it can also be applied to the technical solution of the present invention.

[0038] At the same time, in this embodiment, the ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com