Method for preparing lithium battery electrode material FeSe2 thin film through magnetron sputtering

A magnetron sputtering and electrode material technology, applied in sputtering plating, metal material coating process, ion implantation plating and other directions, can solve the problems of difficult to prepare large-area thin films, expensive preparation equipment, large energy consumption, etc. Achieve the effects of high magnetron sputtering efficiency, good repeatability and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

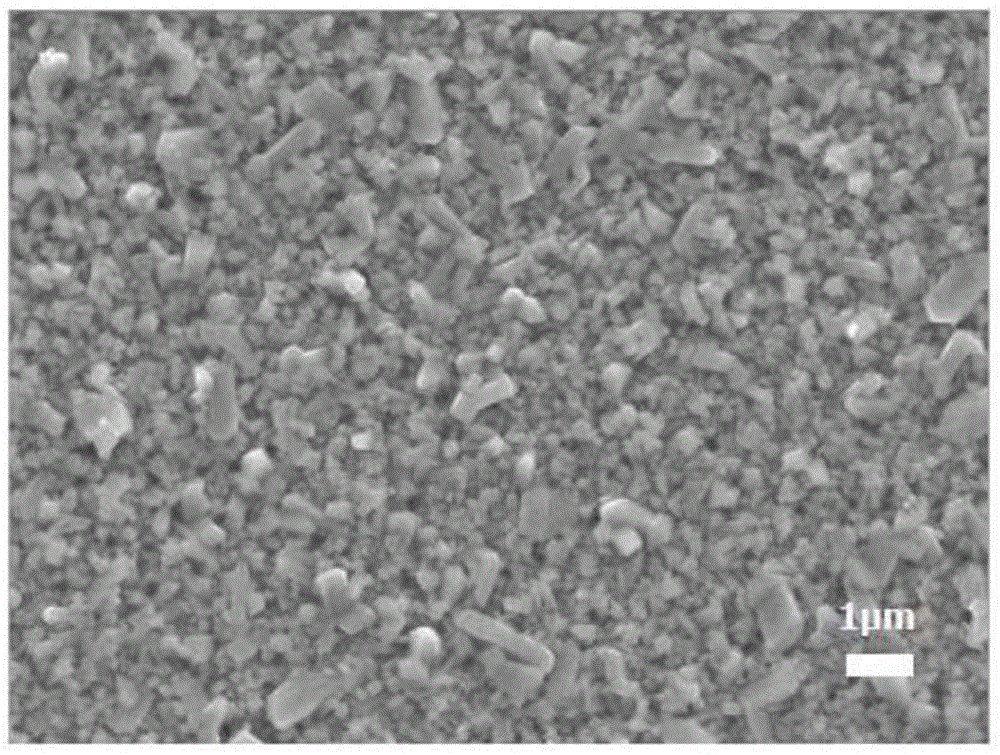

Image

Examples

Embodiment 1

[0028] Preparation of lithium battery electrode material FeSe by magnetron sputtering 2 A thin film method comprising the steps of:

[0029] a, sputtering preparation: select the silicon substrate as the substrate for magnetron sputtering, select the FeSe target material with a purity of 99.99% as the sputtering target material for magnetron sputtering, clean the silicon substrate; The silicon substrate and the FeSe target are installed at corresponding positions in the magnetron sputtering chamber, and the distance from the FeSe target to the silicon substrate is adjusted to 7cm;

[0030] b. Sputtering deposition: evacuate the vacuum chamber to a pressure less than 2×10 -4 Pa, then feed argon with a purity of 99.995% as the working gas, adjust the sputtering pressure to 0.5Pa, the substrate temperature to 600°C, the sputtering power to 60W, and deposit a thin film on the silicon substrate after 0.5h of sputtering;

[0031] c. Post-annealing treatment: the silicon substrate ...

Embodiment 2

[0037] Preparation of lithium battery electrode material FeSe by magnetron sputtering 2 A thin film method comprising the steps of:

[0038] a, sputtering preparation: select the silicon substrate as the substrate for magnetron sputtering, select the FeSe target material with a purity of 99.99% as the sputtering target material for magnetron sputtering, clean the silicon substrate; The silicon substrate and the FeSe target are installed at corresponding positions in the magnetron sputtering chamber, and the distance from the FeSe target to the silicon substrate is adjusted to 5cm;

[0039] b. Sputtering deposition: evacuate the vacuum chamber to a pressure less than 2×10 -4Pa, then feed argon gas with a purity of 99.995% as the working gas, adjust the sputtering pressure to 0.45Pa, the substrate temperature to 500°C, the sputtering power to 80W, and deposit a thin film on the silicon substrate after 1h of sputtering;

[0040] c. Post-annealing treatment: the silicon substrat...

Embodiment 3

[0044] Preparation of lithium battery electrode material FeSe by magnetron sputtering 2 A thin film method comprising the steps of:

[0045] a, sputtering preparation: select the silicon substrate as the substrate for magnetron sputtering, select the FeSe target material with a purity of 99.99% as the sputtering target material for magnetron sputtering, clean the silicon substrate; The silicon substrate and the FeSe target are installed at corresponding positions in the magnetron sputtering chamber, and the distance from the FeSe target to the silicon substrate is adjusted to 6cm;

[0046] b. Sputtering deposition: evacuate the vacuum chamber to a pressure less than 2×10 -4 Pa, then feed argon gas with a purity of 99.995% as the working gas, adjust the sputtering pressure to 0.55Pa, the substrate temperature to 400°C, the sputtering power to 70W, and deposit a thin film on the silicon substrate after 0.7h of sputtering;

[0047] c. Post-annealing treatment: the silicon subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com