Low-alcohol-content alcoholic beverage brewed with dry flowers and preparation process thereof

A preparation process and a technology for dried flowers, which are applied to the field of brewing low-alcohol beverage wine from dried flowers and the preparation thereof, can solve the problems of unfavorable product quality of fermented grains, difficult to control flavor substances, and high production costs, and achieve fresh and pleasant floral fragrance and wine body. Plumping, anti-aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A low-alcohol drinking wine brewed from dried flowers and its preparation process. The main raw materials are malt syrup, white sugar, water and dried chrysanthemum petals, and the white granulated sugar and malt sugar are converted into low-alcohol wine by active dry yeast. During the fermentation process, dry petals are added to participate in the fermentation. After the fermentation is completed, xylitol, citric acid, and sodium citrate are used to prepare the finished product. The ratio of fermentation raw material maltose syrup to white sugar is 3:1, and the amount of dried chrysanthemum petals added It is 2.0g / L.

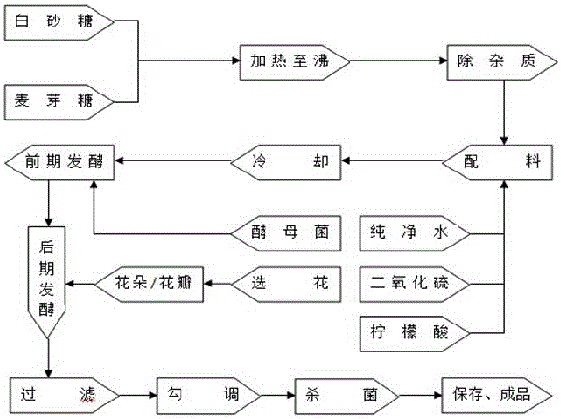

[0023] The manufacture technology of brewing low-alcohol beverage wine from above-mentioned dried flower comprises the following steps:

[0024] 1. Pre-fermentation: First, mix maltose syrup and white sugar in a ratio of 3:1, boil, filter out impurities, and obtain mixed syrup A. Use citric acid and purified water to adjust the pH to 3.0, and adjust th...

Embodiment 2

[0032] The invention discloses a low-alcohol drinking wine brewed from dried flowers and its preparation process. Maltose syrup, white granulated sugar, water and dried rose petals are used as main preparation raw materials, and the white granulated sugar and maltose are converted into low-alcohol wine by active dry yeast. During the fermentation process, dry petals are added to participate in the fermentation. After the fermentation is completed, xylitol, citric acid, and sodium citrate are used to prepare the finished product. The ratio of fermentation raw material maltose syrup to white sugar is 3:1, and the amount of dry rose petals added It is 2.5g / L.

[0033] The manufacture technology of brewing low-alcohol beverage wine from above-mentioned dried flower comprises the following steps:

[0034]1. Pre-fermentation: First, mix maltose syrup and white sugar in a ratio of 3:1, boil, filter out impurities, and obtain mixed syrup A. Use citric acid and purified water to adjus...

Embodiment 3

[0042] A low-alcohol drinking wine brewed from dried flowers and a preparation process thereof. The main preparation raw materials are maltose syrup, white sugar, water and dried osmanthus flower petals, and the white granulated sugar and maltose are converted into low-alcohol wine by active dry yeast. During the fermentation process, dry petals are added to participate in the fermentation. After the fermentation is completed, xylitol, citric acid, and sodium citrate are used to prepare the finished product. The ratio of fermentation raw material maltose syrup to white sugar is 2:1, and the amount of dried osmanthus petals added It is 3.0g / L.

[0043] The manufacture technology of brewing low-alcohol beverage wine from above-mentioned dried flower comprises the following steps:

[0044] 1. Pre-fermentation: First, mix maltose syrup and white sugar in a ratio of 2:1, boil, filter out impurities, and obtain mixed syrup A. Use citric acid and purified water to adjust the pH to 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com