Synthetic industrial acidic wastewater vapor blocking agent and preparation method thereof

A technology of acidic wastewater and blocking agent, which can be applied in other chemical processes, chemical instruments and methods, etc., and can solve problems such as inability to meet environmental protection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

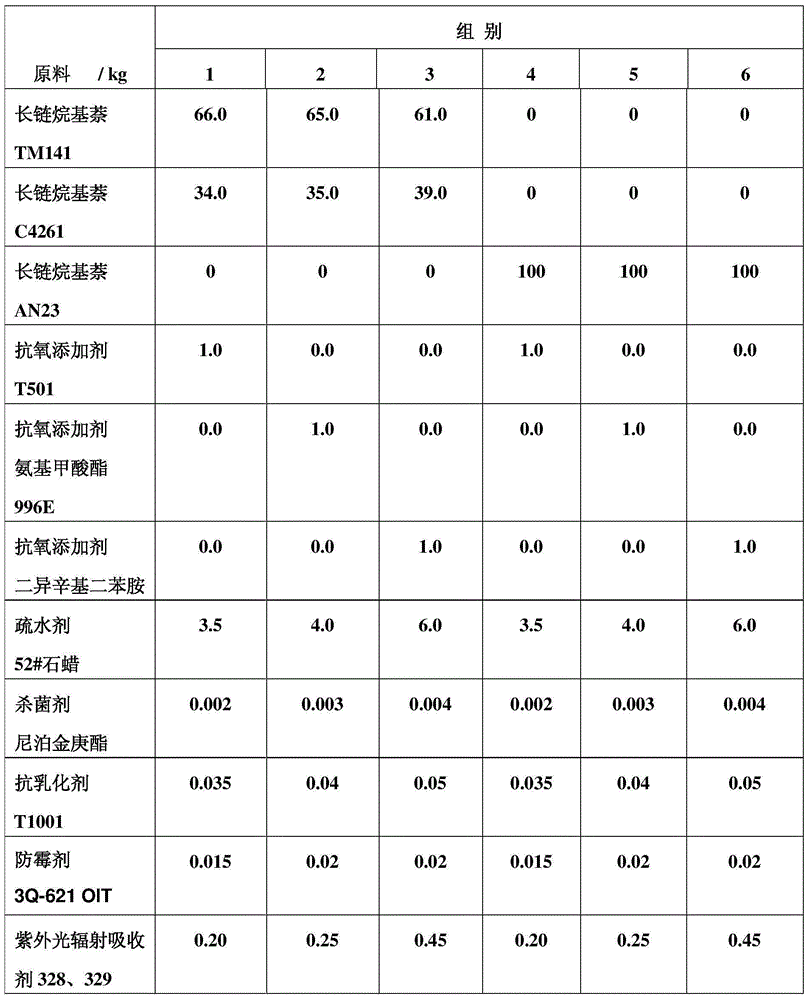

[0038] The raw materials are alkylnaphthalene TM141 and alkylnaphthalene C4261 produced by Shanghai Zejun Trading Co., Ltd., and 37.0kg of long-chain alkylnaphthalene TM141 and 23.0kg of long-chain alkylnaphthalene C4261 are metered and pumped into the normal pressure blending kettle, heated to 40-60°C.

[0039] The remaining 28.0kg of long-chain alkylnaphthalene TM141 and 12.0kg of long-chain alkylnaphthalene C4261 were heated to 80-90°C in a small heating device, and then 1.0kg of antioxidant additive carbamate 996E, 4.0kg of Hydrophobic agent 52# paraffin, 0.02kg of antifungal agent 3Q-621OIT, 0.003kg of fungicide heptylparaben, 0.25kg of ultraviolet radiation absorber 329, 0.04kg of anti-emulsifier T1001 are measured and added to the long chain Alkyl naphthalene TM141 and long-chain alkyl naphthalene C4261 mixed solution, stir evenly to make mother liquor.

[0040] Add the above-prepared mother liquor into the blending tank and stir evenly to obtain the synthetic industri...

Embodiment 2

[0042] The raw material is alkylnaphthalene AN23 from Shanghai Naco Lubrication Technology Co., Ltd., and 60.0kg of long-chain alkylnaphthalene AN23 is metered and pumped into an atmospheric pressure mixing kettle and heated to 40-60°C.

[0043] The remaining 40.0kg of long-chain alkyl naphthalene AN23 is heated to 80-90°C, and then 1.0kg of antioxidant additive carbamate 996E, 4.0kg of hydrophobic agent 52# paraffin, and 0.02kg of antifungal agent 3Q-621OIT , 0.003kg of fungicide heptylparaben, 0.25kg of ultraviolet radiation absorber 329, 0.04kg of anti-emulsifier T1001 metered and sequentially added to the long-chain alkyl naphthalene AN23 solution, stirred evenly to form a mother liquor.

[0044] Add the above-prepared mother liquor into the kettle and stir evenly to obtain the synthetic industrial acidic waste water vapor barrier agent of this embodiment.

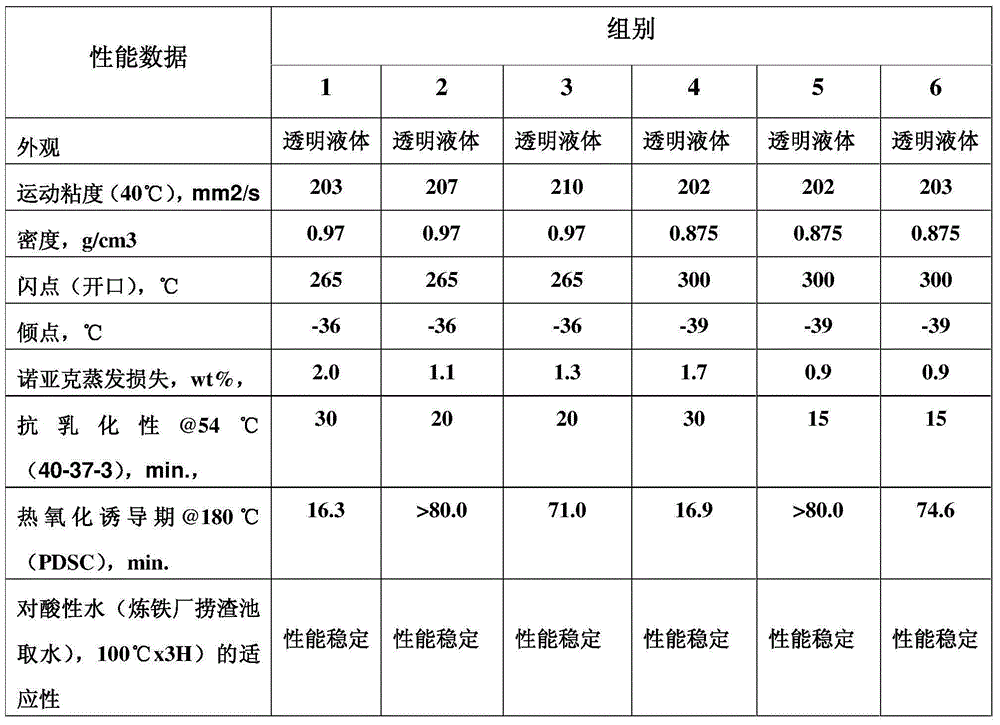

[0045] Use the blend of long-chain alkylnaphthalene TM141 and alkylnaphthalene C4261 or the single compound of alkyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com