Liquid calcium/zinc heat stabilizer, preparing method thereof and device for implementing method

A heat stabilizer and liquid calcium technology, applied in the field of liquid calcium/zinc heat stabilizers, can solve the problems of manual transfer of semi-finished products, great harm to operators, long production time cycle, etc., to reduce unsafe factors and short production cycle , The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

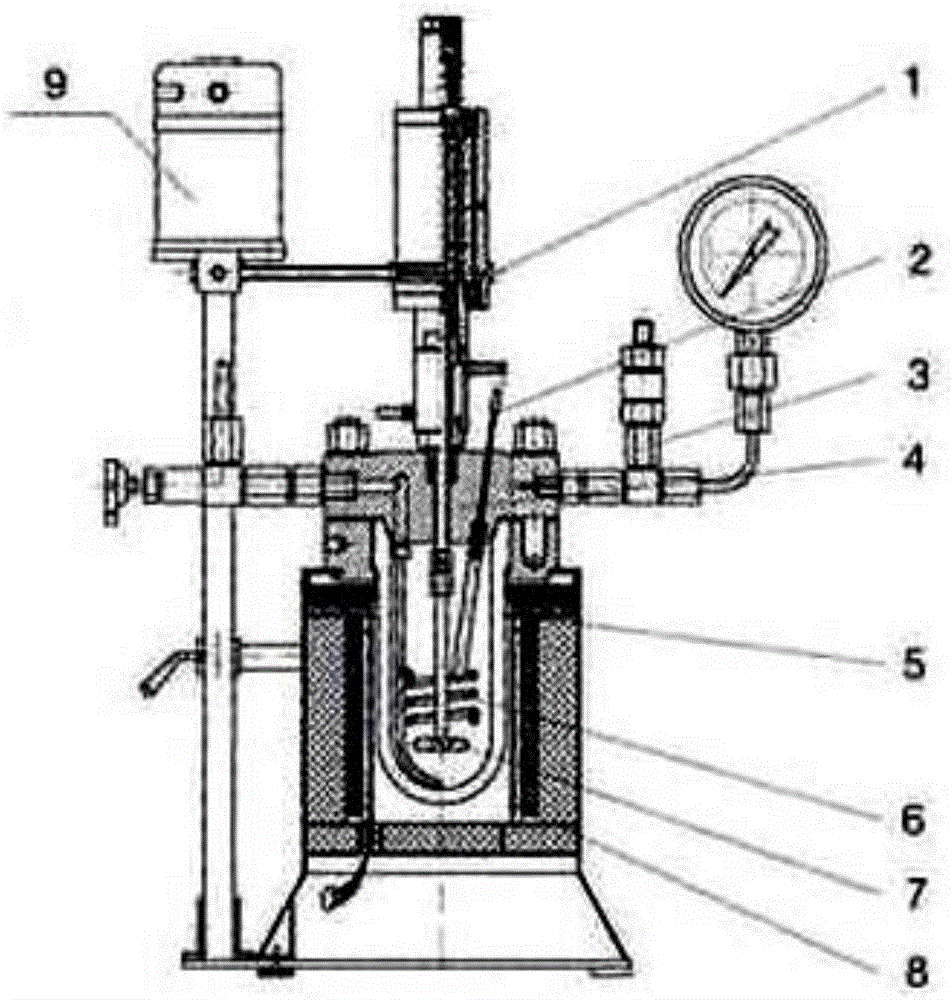

Image

Examples

Embodiment 1

[0054] A liquid calcium / zinc heat stabilizer, comprising the following preparation raw materials in parts by weight: 10 parts of calcium hydroxide, 15 parts of zinc oxide, 36 parts of acid solution, 0.6 parts of catalyst, 1 part of water-carrying agent, and 17 parts of saturated naphthenic solvent , 20 parts of heat-resistant additives;

[0055] Among them, the acid solution is a mixture of 8 parts of isooctanoic acid, 3 parts of octanoic acid, 18 parts of oleic acid, 4 parts of p-tert-butylbenzoic acid and 3 parts of benzoic acid, the catalyst is a mixture of 0.5 parts of acetic acid and 0.1 part of formic acid, and the water carrier It is 1 part of ethylene glycol, the saturated cycloalkane solvent is a mixture of butanone, 7 parts of odorless kerosene and 2 parts of albino oil, and the heat-resistant additive is a mixture of 12 parts of soybean oil and 8 parts of phosphite ester.

[0056] A preparation method of liquid calcium / zinc heat stabilizer, comprising the following ...

Embodiment 2

[0063] A liquid calcium / zinc heat stabilizer, comprising the following preparation raw materials in parts by weight: 15 parts of calcium oxide, 18 parts of zinc oxide, 40 parts of acid solution, 1 part of catalyst, 1 part of water-carrying agent, 12 parts of saturated naphthenic solvent, 14 parts of heat-resistant additive;

[0064] Among them, the acid liquid is a mixture of 20 parts of oleic acid and 20 parts of isooctanoic acid, the catalyst is 1 part of propionic acid, the water-carrying agent is 1 part of ethylene glycol, the saturated naphthenic solvent is 12 parts of deodorized kerosene, and the heat-resistant additive is 1 part A mixture of 1 part SBM and 2 parts DBM, 5 parts soybean oil, 6 parts phosphite.

[0065] A preparation method of liquid calcium / zinc heat stabilizer, comprising the following steps:

[0066] 201. Pre-heat the oil bath temperature of the reactor to 135°C, add 40 parts of acid solution into the reactor, cover the lid of the reactor, start stirri...

Embodiment 3

[0072] A liquid calcium / zinc heat stabilizer, comprising the following preparation raw materials in parts by weight: 15 parts of calcium hydroxide, 20 parts of zinc oxide, 40 parts of acid solution, 1 part of catalyst, 2 parts of water-carrying agent, and 10 parts of saturated naphthenic solvent , 13 parts of heat-resistant additives;

[0073] Among them, the acid liquid is a mixture of 28 parts of isooctanoic acid and 12 parts of p-tert-butylbenzoic acid, the catalyst is a mixture of 0.6 parts of acetic acid, 0 part of formic acid and 0.4 part of propionic acid, and the water carrier is 2 parts of methanol, saturated naphthenic solvent It is a mixture of 0 parts of triethylene glycol and 10 parts of cyclohexanone, and the heat-resistant additive is a mixture of 8 parts of soybean oil, 4 parts of phosphite ester and 1 part of antioxidant.

[0074] A preparation method of liquid calcium / zinc heat stabilizer, comprising the following steps:

[0075] 301. Preset the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com