Ultrasonic anti-sticking device

An anti-adhesion device and ultrasonic technology, applied in magnesium halide, gas treatment, membrane technology and other directions, can solve the problems of restricting the sustainability and stability of production, increase the effective utilization of equipment, diverse selection, and structural design. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of this patent will be further described in detail below in conjunction with specific implementations. The technical features or connection relationships described in the present invention that are not described in detail are all the existing technologies used.

[0015] The present invention will be further described in detail below in conjunction with the drawings.

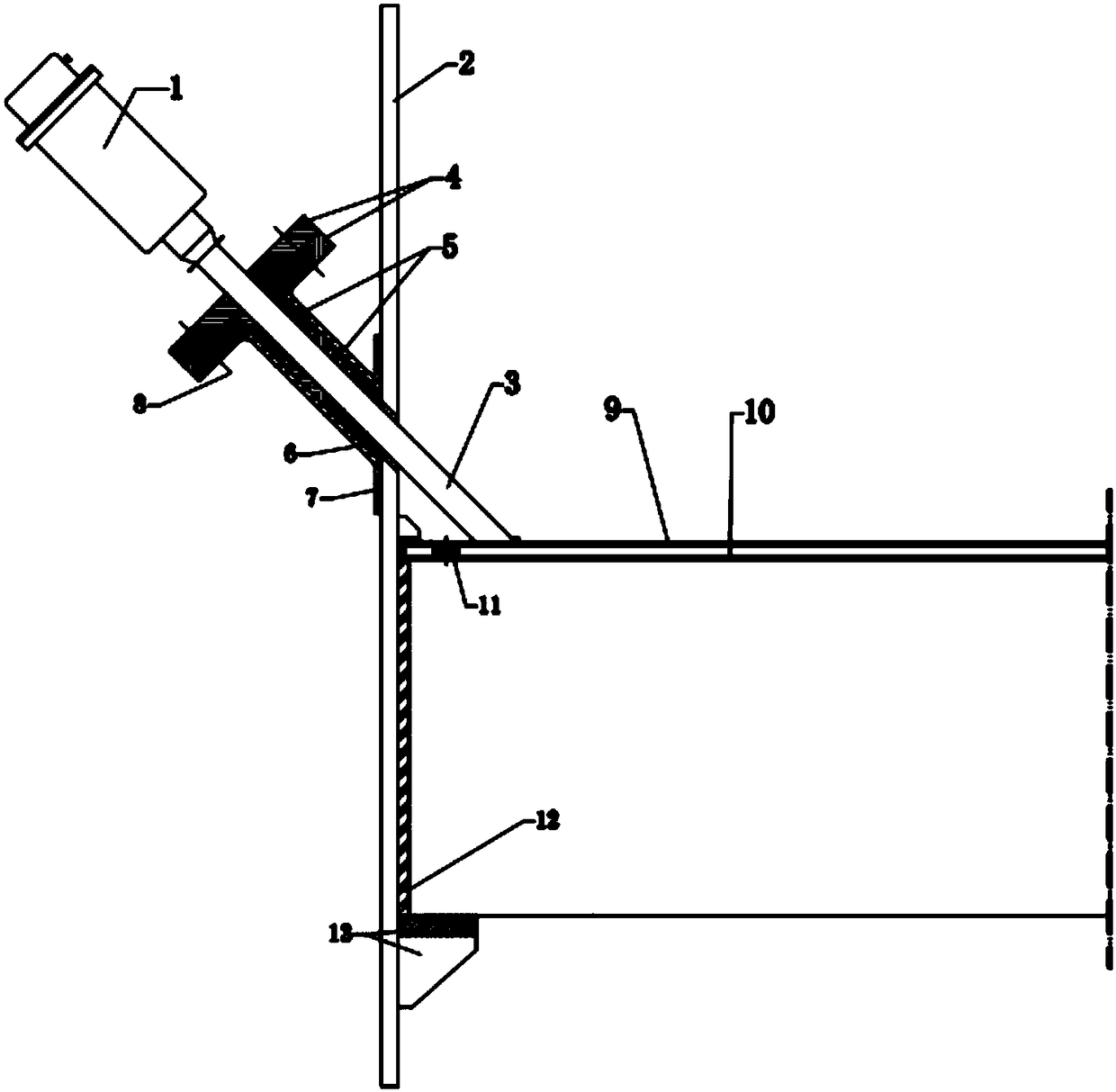

[0016] Such as figure 1 As shown, the ultrasonic anti-adhesion device of the present invention includes a tray support block 11, an ultrasonic generator 1, an ultrasonic guide rod 3, a reinforcing plate 7, and a sealing flange 4. The tray support block 11 is arranged on the upper tower of the drying tower Between the tray 9 and the lower tray 10, a reinforcement plate 7 is provided on the outside of the wall of the drying tower. The reinforcement plate 7 extends diagonally upward to connect with the sealing flange 4, and one end of the ultrasonic guide rod 3 penetrates the sealing flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com