Production method of medicinal rubber plug

A production method and technology for rubber stoppers, which are applied in the production field of medicinal rubber stoppers, can solve the problems of easy infiltration into rubber stoppers, cumbersome manufacturing process, and puncture and chipping due to sealing, and achieve the effect of simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A production method of a medical rubber stopper, the steps are as follows: put the brominated butyl rubber stopper into a vacuum container with a vacuum degree of -0.09Mpa, and conduct heat treatment at 150°C for 50 minutes; The base rubber stopper is first rinsed with an alkaline aqueous solution with a pH value of 10 for 3 minutes, then rinsed with an acidic aqueous solution with a pH value of 3 for 3 minutes, and finally rinsed with purified water for 3 minutes, and the temperature of the rinse water is 50°C; Then 350cst of medical grade simethicone is siliconized and dried at 105°C for 60 minutes to obtain a medical butyl rubber stopper that meets the requirements.

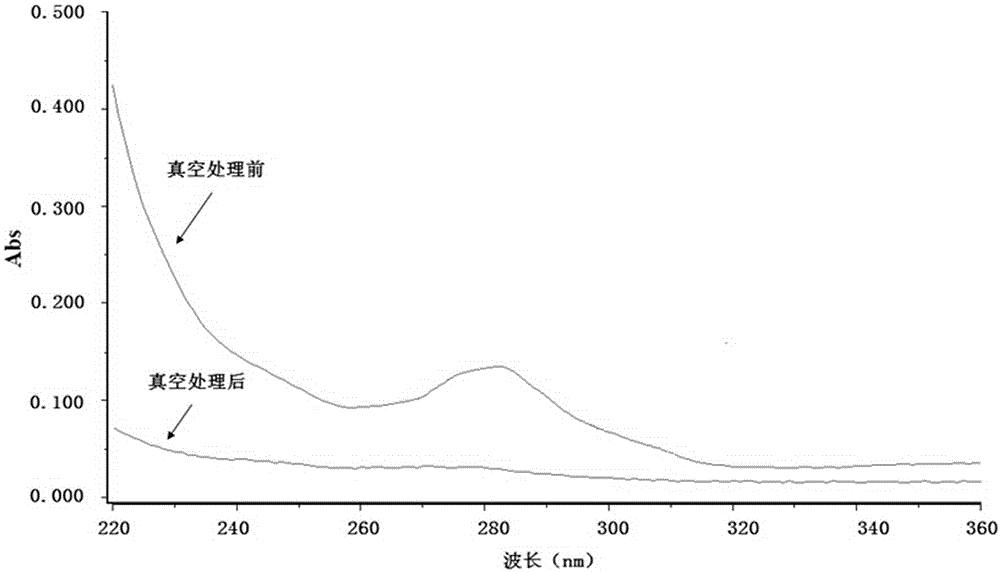

[0023] The basic ultraviolet absorbance of butyl rubber stoppers before and after vacuum heat treatment was tested by ultraviolet spectrophotometer (the extract solution is an alkaline aqueous solution with a pH value of 12), and the reduction of extractables and leachables in butyl rubber stoppers was e...

Embodiment 2

[0025] A production method of a medical rubber stopper, the steps are as follows: put the chlorinated butyl rubber stopper into a vacuum container with a vacuum degree of -0.08Mpa, and conduct heat treatment at 100°C for 100 minutes; The base rubber stopper is first rinsed with an alkaline aqueous solution with a pH value of 9 for 10 minutes, then rinsed with an acidic aqueous solution with a pH value of 2 for 10 minutes, and finally rinsed with purified water for 10 minutes, and the temperature of the rinse water is 100°C; Then 350cst of medical grade simethicone is siliconized and dried at 105°C for 60 minutes to obtain a medical butyl rubber stopper that meets the requirements.

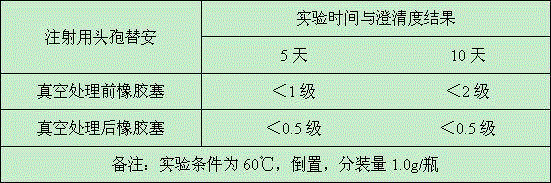

[0026] The results of the compatibility test between the obtained medicinal butyl rubber stopper and cefotiam for injection are shown in Table 1.

[0027] Table 1 Compatibility test results of medicinal butyl rubber stopper and cefotiam for injection

[0028]

Embodiment 3

[0030] A production method of a medical rubber stopper, the steps are as follows: put the chlorinated butyl rubber stopper into a vacuum container with a vacuum degree of -0.09Mpa, and conduct heat treatment at 125°C for 90 minutes; The base rubber stopper is first rinsed with an alkaline aqueous solution with a pH value of 13 for 50 minutes, then rinsed with an acidic aqueous solution with a pH value of 1 for 50 minutes, and finally rinsed with purified water for 50 minutes, and the temperature of the rinse water is 70°C; Then 350cst of medical grade simethicone is siliconized and dried at 105°C for 60 minutes to obtain a medical butyl rubber stopper that meets the requirements.

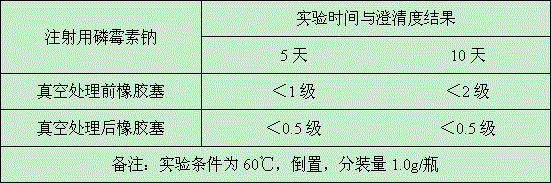

[0031] The results of the compatibility test between the obtained medicinal butyl rubber stopper and fosfomycin sodium for injection are shown in Table 2.

[0032] Table 2 Compatibility test results of medicinal butyl rubber stopper and fosfomycin sodium for injection

[0033]

[0034] As can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com