Omega-shaped coal dropping pipe coal conveying system with high-frequency vibration device

A high-frequency vibration and coal conveying system technology, applied in the field of coal conveying pipeline system, can solve problems such as difficult dredging, large dust, easy blockage, etc., to slow down the impact of falling coal, reduce noise and dust, prevent coal blockage and dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

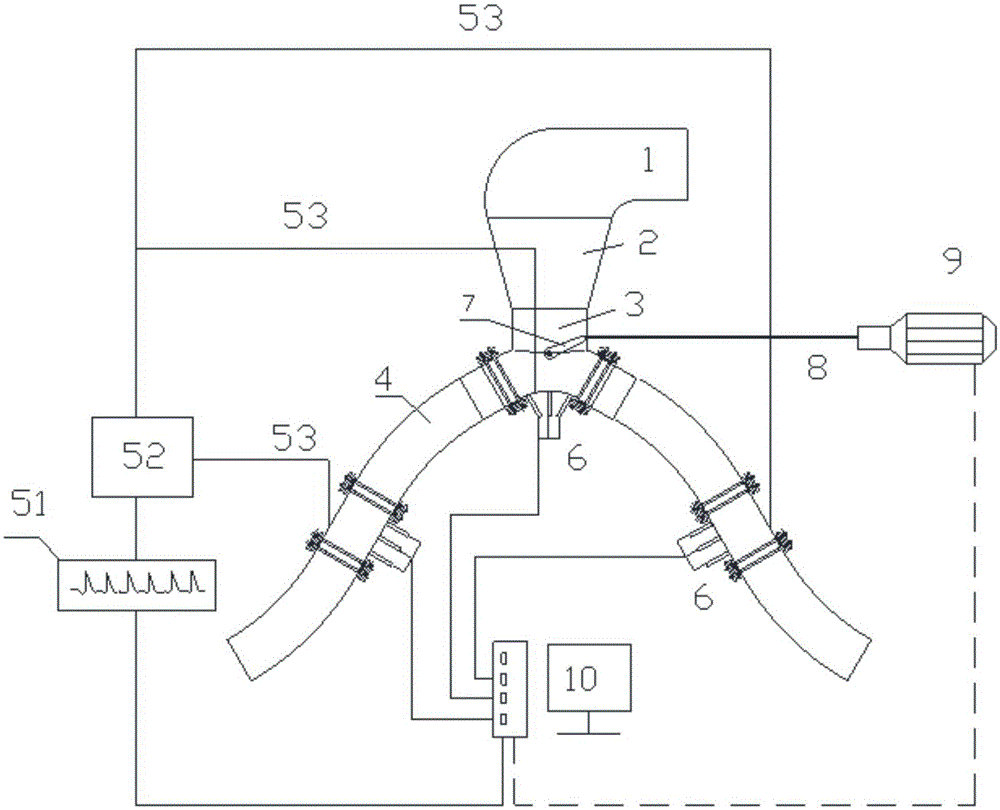

[0042] The Ω briquette transfer mechanical device includes a dust cover 1, a tapered funnel 2, an arc tee 3 and an Ω-shaped double drop pipe. The coal transported from the upstream first enters the dustproof cover 1, the function of the dustproof cover 1 is to prevent the coal dust, and then enters the throat drop coal funnel 2, and the coal in the throat drop coal funnel 2 is simply accumulated and mixed, and then flows into the arc In the shape tee 3, through the material distribution and diversion of the arc tee 3, it enters the two streamlined branch pipes of the Ω-shaped double drop pipe 4 respectively, and finally flows into the downstream conveying device.

[0043] The dust cover 1 does not bear any force, but only plays a dust-proof role. There is no specific requirement for the structure. The material is made of plastic PVC. Funnel 2 is connected.

[0044] Described conical funnel 2 is circular frustum structure, and material selects bimetal composite plate, has the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com