Continuous drawing device and sheet nut stamped part manufacturing device and method

A technology for thin-plate nuts and manufacturing equipment, which is applied in the direction of nuts, feeding devices, positioning devices, etc., can solve the problems of difficult machining deviation, high cost, and large thread deviation, and achieve the effect of improving wall thickness uniformity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention is described below in conjunction with accompanying drawing

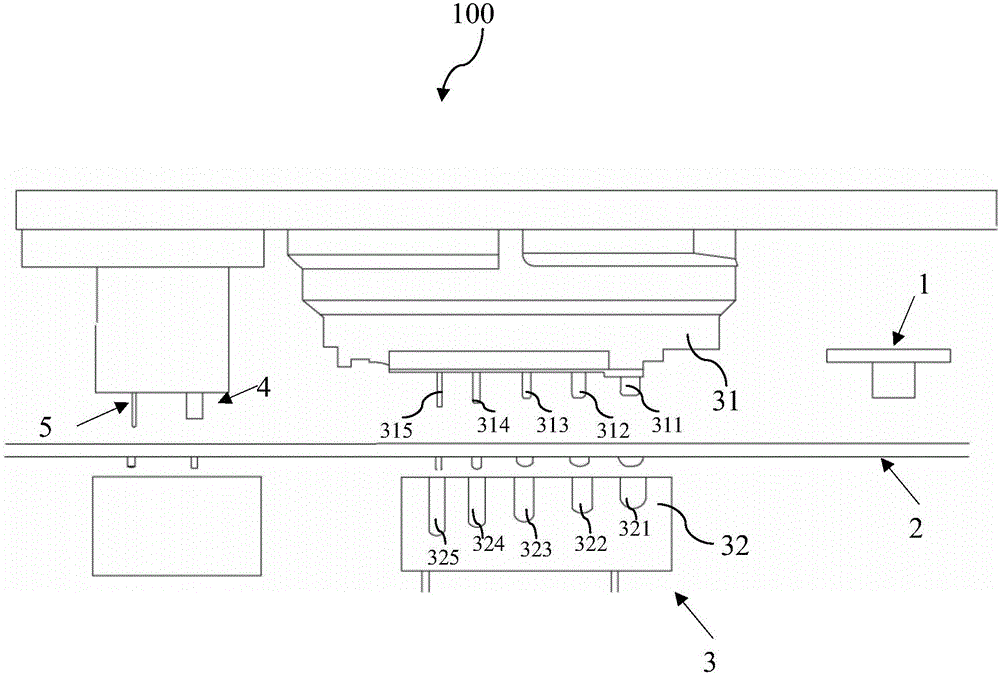

[0028] figure 1 It is a perspective view of the thin plate nut stamping part manufacturing equipment involved in the embodiment of the present invention.

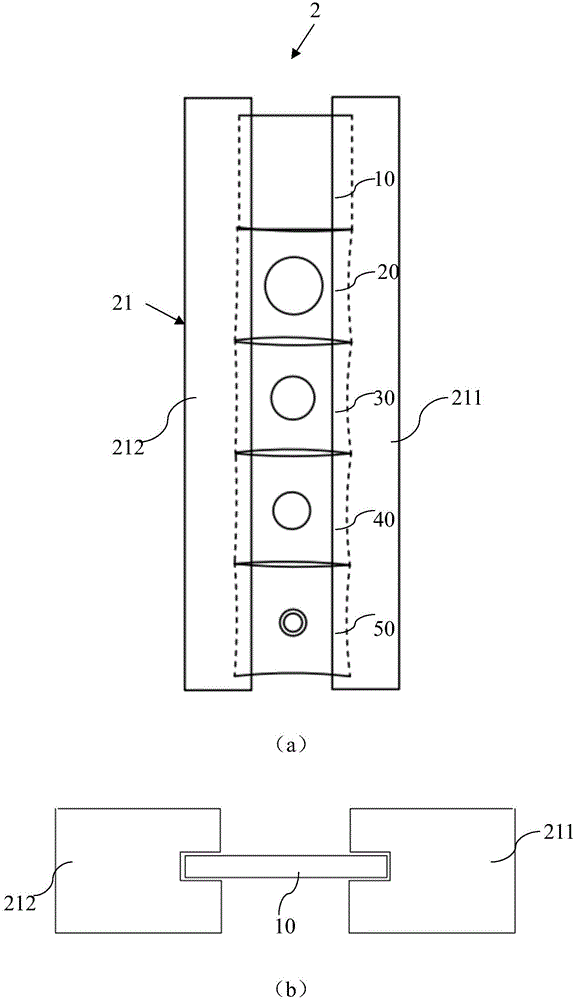

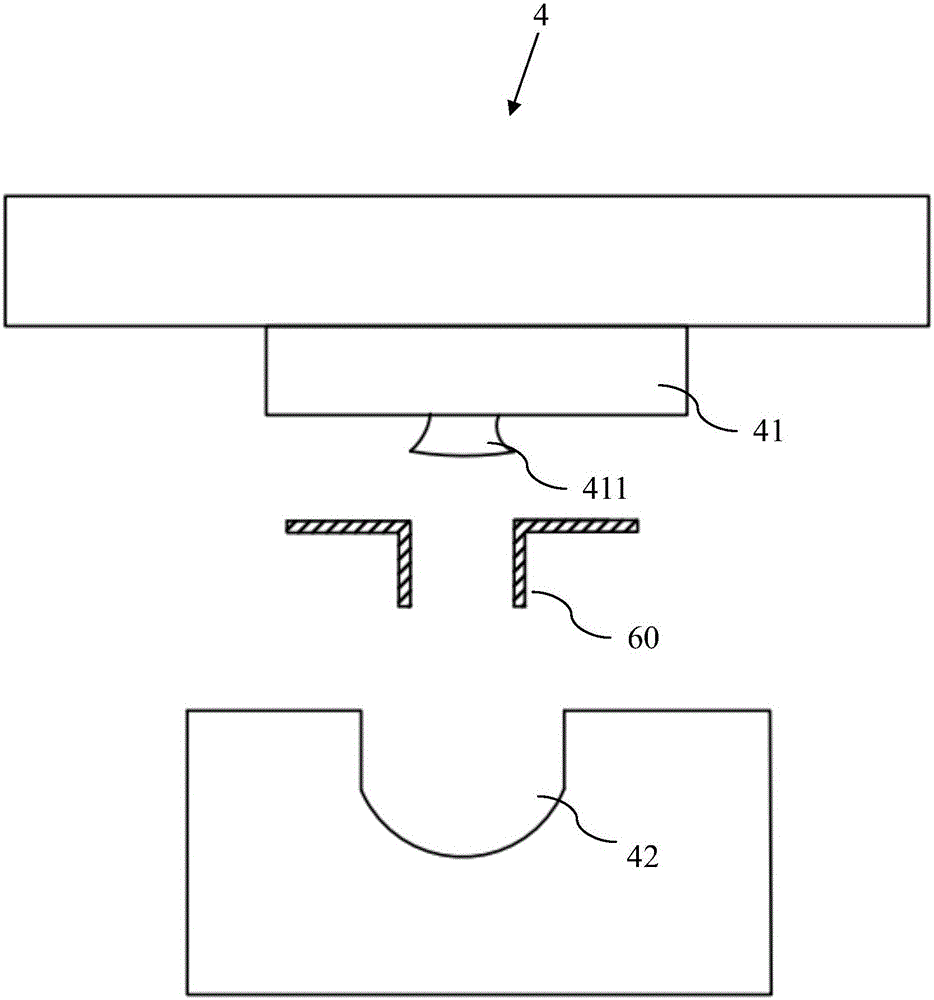

[0029] like figure 1 As shown, the manufacturing equipment 100 for sheet nut stamped parts includes a coil cutting device 1 , a conveying device 2 , a continuous drawing device 3 , an upsetting and leveling device 4 , a punching device 5 and a control device not shown in the figure.

[0030] The coil cutting device 1 is used to cut the coil material delivered by the upper device into blanks of a certain size; the conveying device 2 is used to transport the blanks along the conveying path; the continuous drawing device 3 is used to continuously draw the blanks to form a deep drawing Parts; upsetting and leveling device 4 is used to upset and level the drawn parts to form upsetting parts; punching device 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com