Water-sweeping, drying and inerting integrated process for natural gas transportation pipeline

A technology for transporting pipelines and natural gas, which is applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., which can solve the problems of waste of equipment fuel, high cost, and multiple ball passes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

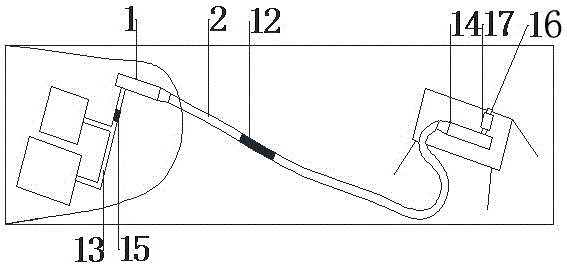

[0023] In this specific embodiment, the integrated process of water sweeping, drying and inerting of the natural gas pipeline provided by the present invention is used in the work of water sweeping, drying and inerting of the submarine natural gas pipeline, and the process flow chart is as follows figure 1 As shown, the implementation process includes the following steps:

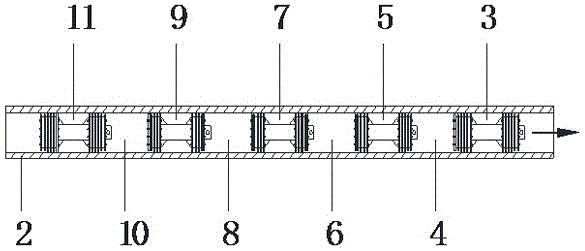

[0024] a. Load the pig train 12 into the submarine natural gas transmission pipeline 2 through the ball tube 1 at the head end of the pipeline. The pig train 12 includes multiple pigs, and also includes a fresh water slug 4 and a water-based gel slug 6 , chemical desiccant slug 8, dry gas slug 10, the fresh water slug 4, water-based gel slug 6, chemical desiccant slug 8, and dry gas slug 10 are arranged alternately with the pig in sequence respectively, The sequence of loading into the submarine natural gas pipeline 2 is: pig one 3, fresh water slug 4, pig two 5, water-based gel slug 6, pig three 7, chemica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com