Method for synthetizing tungstate/tungsten oxide heterojunction photocatalyst in situ

A photocatalyst, in-situ synthesis technology, applied in the direction of protection device against harmful chemicals, etc., can solve the problems of limited practical application, complicated preparation route, increased catalyst preparation cost, etc., to widen the light response range, and the preparation process is easy to operate. , the effect of improving the photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

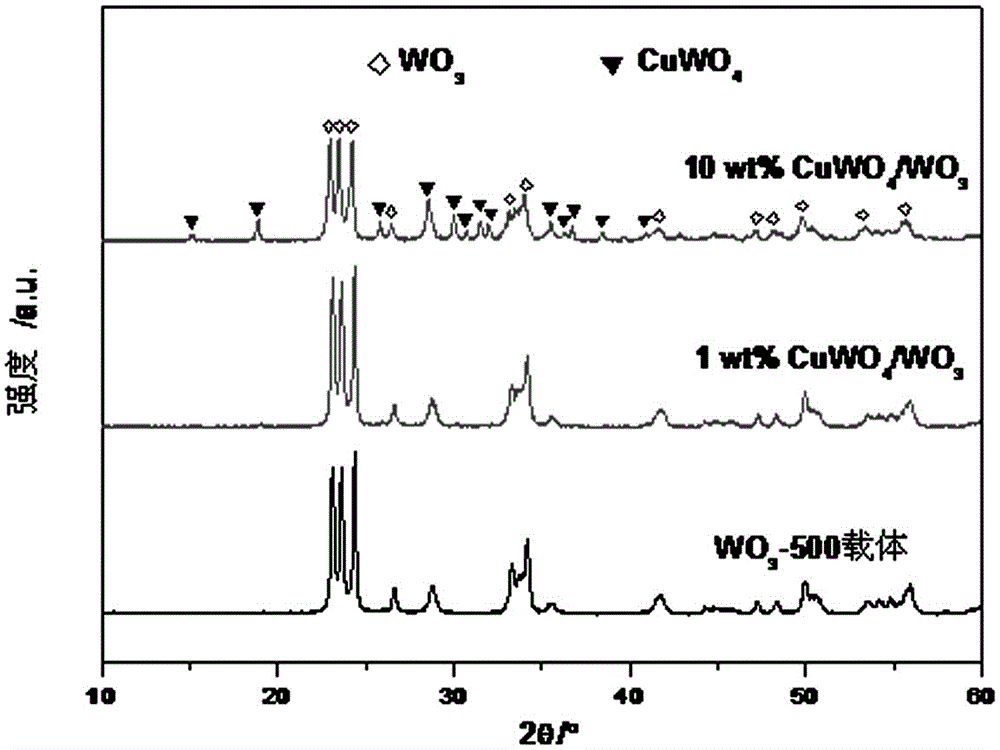

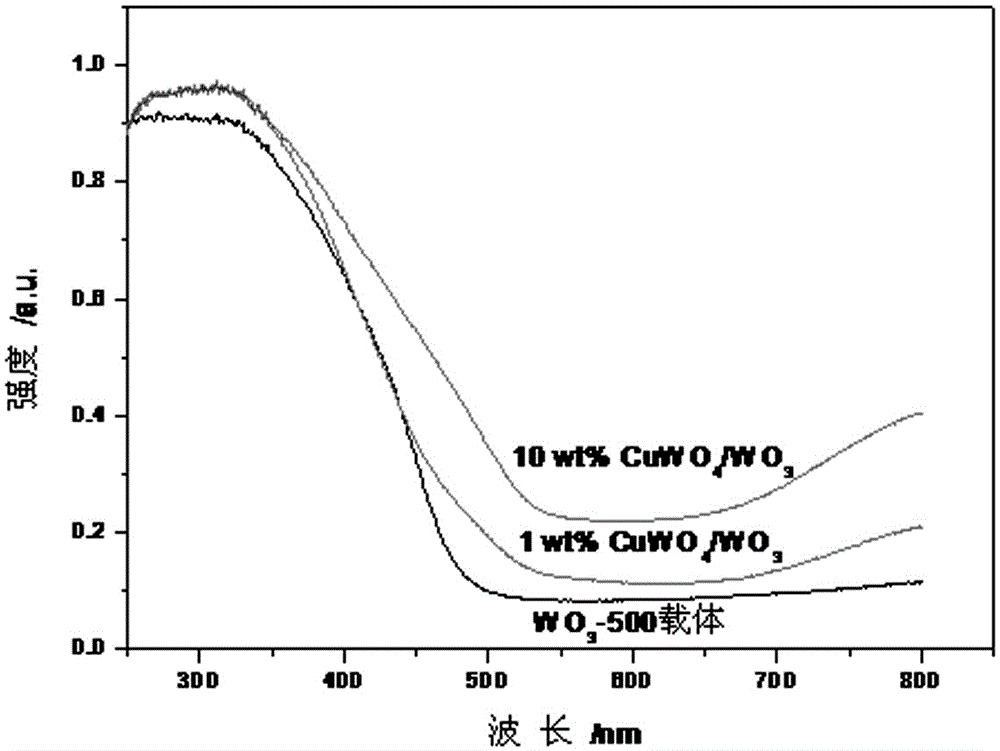

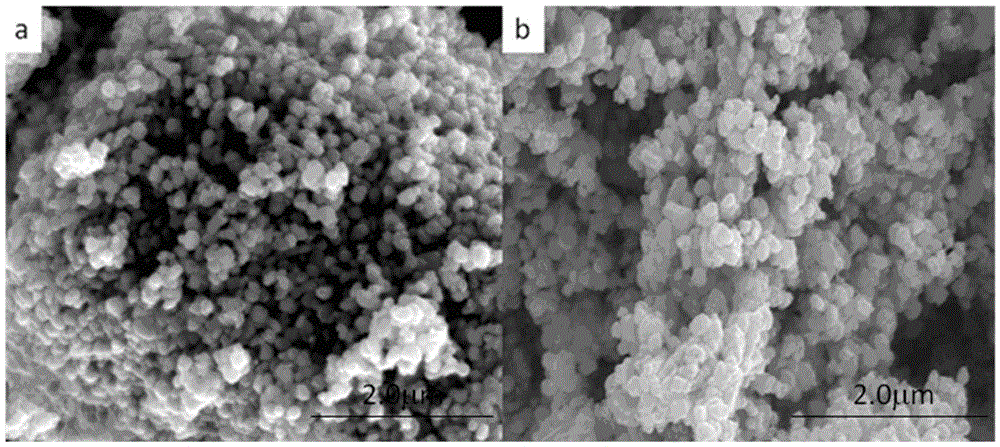

[0035] Preparation and Photocatalytic Activity of Copper Tungstate / Tungsten Oxide Heterojunction Photocatalyst

[0036] 1.1 CuWO 4 / WO 3 The preparation method of heterojunction photocatalyst comprises the following steps:

[0037] (1) Weigh 15g of ammonium tungstate and dissolve it in 150mL of deionized water, heat it in a water bath to dissolve it, and add 3mol·L -1 After adding 250mL of nitric acid, heat in a water bath at 80°C for 1 hour, and age for 12 hours. The precipitate was centrifuged, washed, and dried at 80°C to obtain WO 3 ·H 2 O;

[0038] (2) For the WO obtained in step (1) 3 ·H 2 O, calcined at 500°C for 6h to obtain WO 3 carrier;

[0039] (3) Prepare a series of concentrations of Cu(NO 3 ) 2 solution, respectively, 1.0gWO 3 The support was impregnated with equal volume in Cu(NO 3 ) 2 In the solution (the mass ratio of metal element Cu to W is 0.2%, 0.5%, 1%, 3%, 5%, 7%, 10%), stand still for 24h, stir and dry in a water bath at 90°C. During this...

Embodiment 2

[0051] Preparation and photocatalytic activity of zinc tungstate / tungsten oxide heterojunction photocatalyst

[0052] 2.1 ZnWO 4 / WO 3 The preparation method of heterojunction photocatalyst comprises the following steps:

[0053] wxya 4 / WO 3 The preparation method of the heterojunction photocatalyst is with reference to embodiment 1 (1.1), and the difference is that in step (2), the WO 3 ·H 2 The calcination temperature of O was changed to 600°C, the calcination time was extended to 30h, and in step (3), the Cu(NO 3 ) 2 The solution was changed to Zn(NO 3 ) 2 solution. exist Figure 5 Monoclinic phase WO was observed in 3 At the same time, ZnWO was observed at 2θ=15.4°, 18.8°, 30.4°, 30.6°, 31.1°, 36.3°, 36.6°, 38.3°, 41.2°, 51.7° 4 Diffraction peak, illustrates that the sample that makes in the embodiment 2 is ZnWO 4 / WO 3 heterojunction photocatalysts.

[0054] 2.2 ZnWO 4 / WO 3 Photocatalytic activity of heterojunction photocatalysts:

[0055] For ZnWO in ...

Embodiment 3

[0057] Preparation and photocatalytic activity of manganese tungstate / tungsten oxide heterojunction photocatalyst

[0058] wxya 4 / WO 3 The preparation method of heterojunction photocatalyst is with reference to embodiment 1 (1.1), difference is that in step (3), Cu(NO 3 ) 2 The solution was changed to Mn(NO 3 ) 2 solution, and in step (4), change the roasting temperature to 600°C and extend the time to 12h. Figure 7 (a) is 10wt% MnWO 4 / WO 3 The XRD spectrum of the sample, in the observed monoclinic phase WO 3At the same time, MnWO was observed at 2θ=15.4°, 18.3°, 29.8°, 30.2°, 31.0°, 35.9°, 37.2°, 40.3°, 40.8°, 51.0° 4 Diffraction peaks, illustrating that the sample obtained in Example 3 is MnWO 4 / WO 3 heterojunction photocatalysts. The photocatalytic degradation experiment followed the method of 1.2 in Example 1. Under the condition of light for 90min, 0.2wt% MnWO 4 / WO 3 The degradation rate of rhodamine B by the heterojunction photocatalyst is 54%, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com