Tennis badminton racket line cutting table

A badminton racket and tangent table technology, applied to rackets, string rackets, sports accessories, etc., can solve problems such as damage to the racket line and racket, large wedge angle, and difficulty in exposing the second line smoothly. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

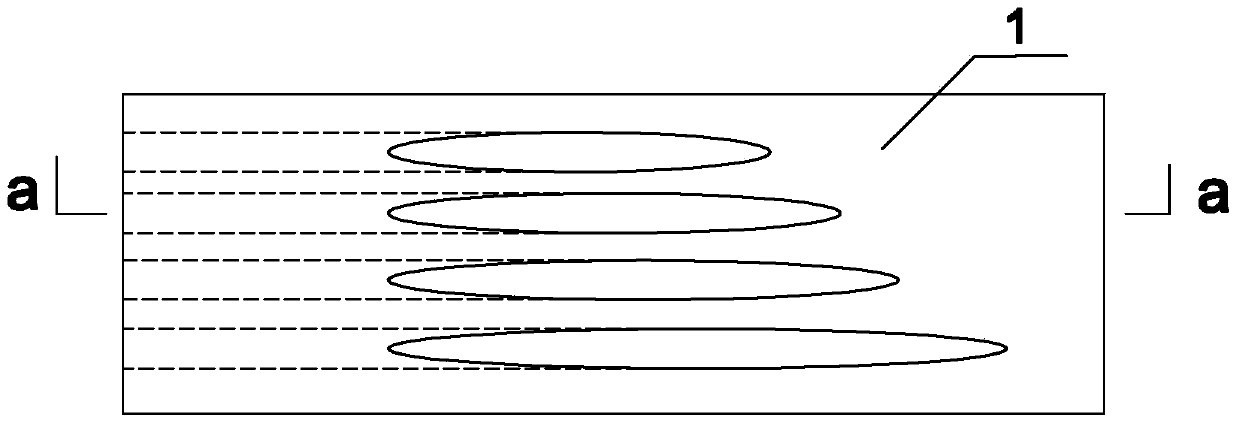

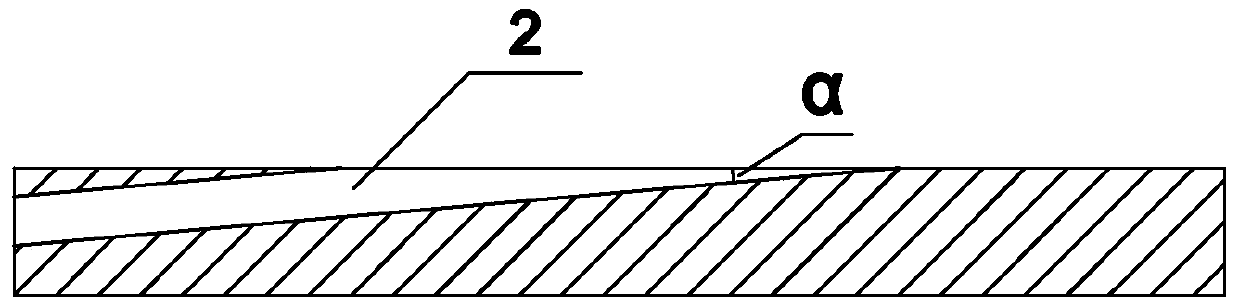

[0014] Example: such as figure 1 As shown, the present invention is a tennis badminton racket thread cutting table, the inside of the thread cutting table 1 is provided with a plurality of thread holes 2 with different inclination angles, different thread hole 2 ends are exposed on the upper surface of the thread cutting table 1, and the ends of the thread holes are The aperture is slightly larger than the diameter of the racket wire 3 .

[0015] The angle α formed between the wire hole 2 and the upper surface of the wire cutting table 1 is between 3 degrees and 6 degrees.

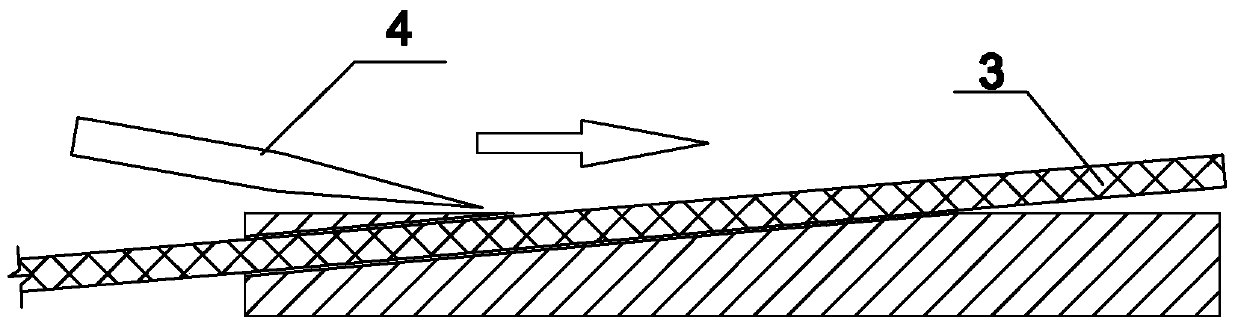

[0016] In the present invention, by using the cooperation of the thread cutting table 1 and the cutter 4, the end of the shooting line 3 can have the same angle as the end of the line hole, making it easier for the shooting line 3 to pass through the line hole 2. Tennis, badminton racket wire cutting table 1 can use metal or similar metal strength material to make.

[0017] When the present invention is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com