Continuous processing production line and processing method of pan-fired green tea

A processing method and production line technology, which is applied in the continuous processing production line and processing field of fried green tea, can solve the problems of low quality and unstable quality of fried green tea, achieve non-scorched edge bursting point, increase aroma concentration and persistence , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

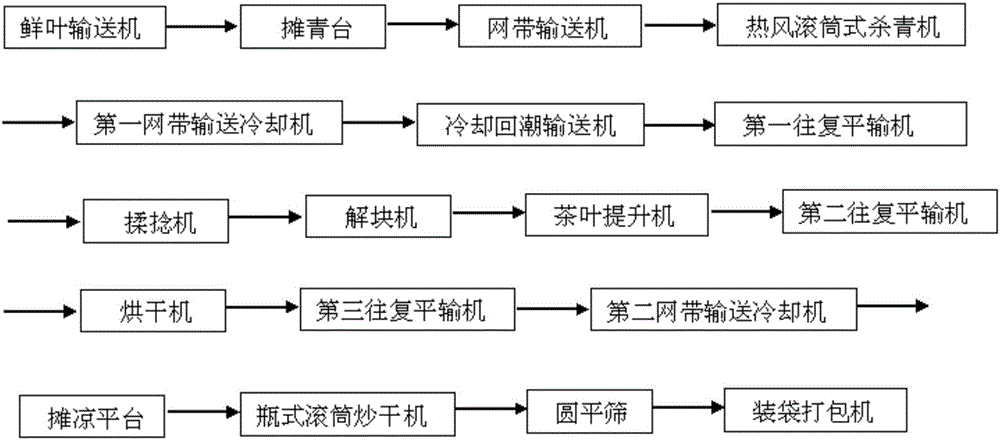

Method used

Image

Examples

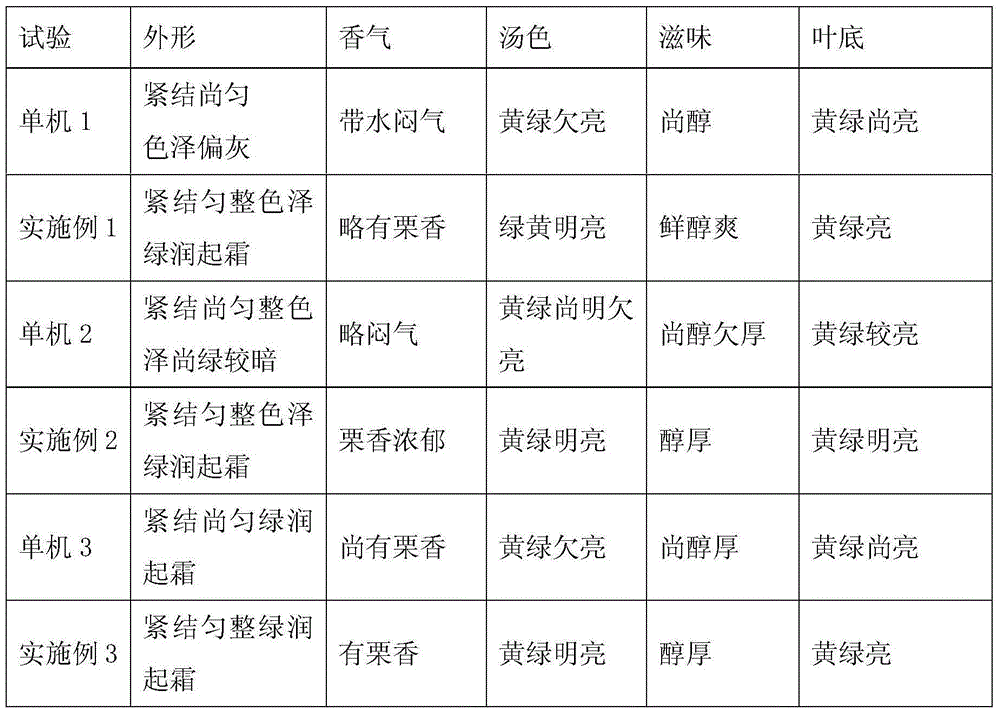

Embodiment 1

[0040] The fresh leaves of Fuyun No. 6 planted by the state-run Fuhu Overseas Chinese Farm Tea Factory in Liucheng County, Liuzhou City, Guangxi are used as fresh leaves, and 1 bud and 2 leaves are picked for continuous processing and direct-fried green tea, and processed according to the following procedures:

[0041] (1) Green stand: spread the picked fresh leaves on the green stand with a thickness of 3-5cm, the relative humidity of the indoor air is 90%, the room temperature is 25±2°C, and the leaf temperature is controlled at 30°C. Below ℃, stand for 4 hours to get green leaves;

[0042](2) Greening: the green leaves are sent to the hot air drum type greening machine through the mesh belt conveyor for greening. The temperature of the hot air is 350 ° C, and the feeding and discharging time is controlled for 70 seconds to obtain green leaves;

[0043] (3) Cooling and resurgence: The green leaves are rapidly cooled by the first mesh belt conveying cooler, the temperature of...

Embodiment 2

[0051] The fresh leaves of Fuding Dahao planted by the state-owned Fuhu Overseas Chinese Farm Tea Factory in Liucheng County, Liuzhou City, Guangxi are used as raw materials, and 1 bud and 2 leaves are picked, and 1 bud and 3 leaves are first developed for continuous processing. The number of leaves accounts for more than 20%, and the number of 1 bud and 3 leaves accounts for more than 70%. It is processed according to the following procedures:

[0052] (1) Green stand: spread the picked fresh leaves on the green stand, the thickness of the stand is 5-8cm, the relative humidity of the indoor air is 85%, the room temperature is 25±2°C, and the leaf temperature is controlled at 30°C. Below ℃, stand for 4 hours to get green leaves;

[0053] (2) Greening: the green leaves are sent to the hot air drum type greening machine through the mesh belt conveyor for greening. The hot air temperature is 400 ° C, and the feeding and discharging time is controlled for 70 seconds to obtain gree...

Embodiment 3

[0062] The fresh leaves of Fuding Dahao planted by the state-run Fuhu Overseas Chinese Farm Tea Factory in Liucheng County, Liuzhou City, Guangxi are used as raw materials, and 1 bud and 3 leaves are picked, and 1 bud and 4 leaves are first developed for continuous processing. Directly fried green tea, of which 1 bud 3 The number of leaves accounts for more than 70%, and the number of 1 bud with 4 leaves accounts for more than 20%. It is processed according to the following procedures:

[0063] (1) Green stand: spread the picked fresh leaves on the green stand with a thickness of 8-10cm, the relative humidity of the indoor air is 90%, the room temperature is 25±2°C, and the leaf temperature is controlled at 30°C. Below ℃, stand for 3.5 hours to get green leaves;

[0064] (2) Greening: the green leaves are sent to the hot air drum type greening machine through the mesh belt conveyor for greening. The temperature of the hot air is 360 ° C, and the time of feeding and discharging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com