Method for optical loss generated by indium tin oxide/metal electrode to organic laser gain layer

A technology of laser gain and metal electrodes, applied to the structure of the active region, etc., can solve the problems of high current density in the active layer, complex manufacturing process, poor conductivity, etc., to achieve improved interface flatness, simple process, and improved performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

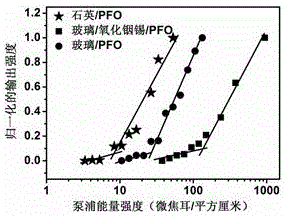

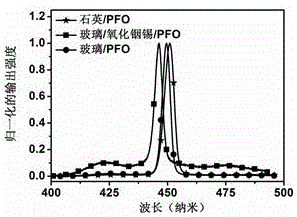

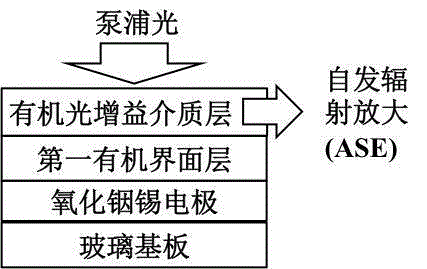

[0028] Combining the commercial material PFO as the gain medium, the influence of different substrates on the amplified spontaneous emission behavior of the gain medium is studied. The results are shown in figure 1 and figure 2 . The comparison shows that the organic laser gain has the lowest threshold on the quartz substrate, while on the indium tin oxide electrode due to the rough surface and relatively high refractive index, resulting in higher light scattering loss and mode leakage loss, corresponding to a higher ASE threshold, Moreover, the corresponding amplified spontaneous emission spectrum is also severely deformed, indicating that the ITO electrode has a serious negative impact on the excitation behavior of the gain medium, including threshold and spectrum.

Embodiment 2

[0030] With cellulose acetate (CA), PEDOT:PSS, PFN + Br - 、PPFN + Br - Three kinds of water-soluble organic interface materials were used to prepare the organic interface layer with the same thickness, indium tin oxide electrode was used, and PFO was used as the organic laser gain medium layer. Figure 4 The experimental results show that PFN + Br - and CA for PFO than PEDOT:PSS and PPFN + Br - more effective.

Embodiment 3

[0032] use PFN + Br - As the material for preparing the organic interface layer, organic interface layers with different thicknesses are prepared between the indium tin oxide electrode and the organic laser gain medium layer. The light with a wavelength of 390nm is used as the pumping light, the device is pumped from one side of the organic laser gain medium layer, and the outgoing light is received at the side end of the organic laser gain medium layer. When the thickness is 15-30nm, the amplification threshold of lasing or spontaneous emission drops significantly.

[0033] By changing the thickness of the organic interface layer, the spontaneous emission amplification threshold is reduced. Due to the introduction of the organic interface layer, the electrode and the organic laser gain medium layer are separated, the optical loss caused by direct contact is avoided, the optical loss of the device is reduced, the laser or spontaneous emission threshold is reduced, and the ef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com