Sulfide solid electrolyte material and preparation method thereof

A technology of solid electrolyte and sulfide, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., and can solve the problems of complicated manufacturing methods, increased costs, and difficulty in industrial scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

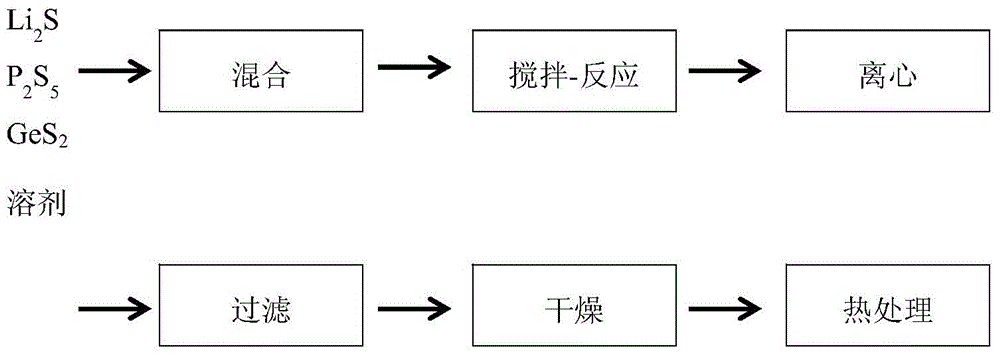

[0038] The present invention also provides a preparation method of the sulfide solid electrolyte material shown in the above formula (I), comprising the following steps:

[0039] A) will Li 2 S, P 2 S 5 , M 2 S n Mix with an organic solvent to obtain a mixed solution; Li 2 S, P 2 S 5 with M 2 S n The molar ratio of x:y:z;

[0040] B) After the mixed solution is stirred-reacted, centrifuged, filtered and dried in sequence, the initial material is obtained;

[0041] C) heat-treating the initial material to obtain a sulfide solid electrolyte material represented by formula (I);

[0042] wxya 2 S·yP 2 S 5 · zM 2 S n (I);

[0043] Wherein, x+y+z=100%; M is one or more of Al, Ge, Ti and La; n is the valence of M. The x, y, and z are the same as those described above, and will not be repeated here.

[0044] The present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0045] In the process of preparing s...

Embodiment 1

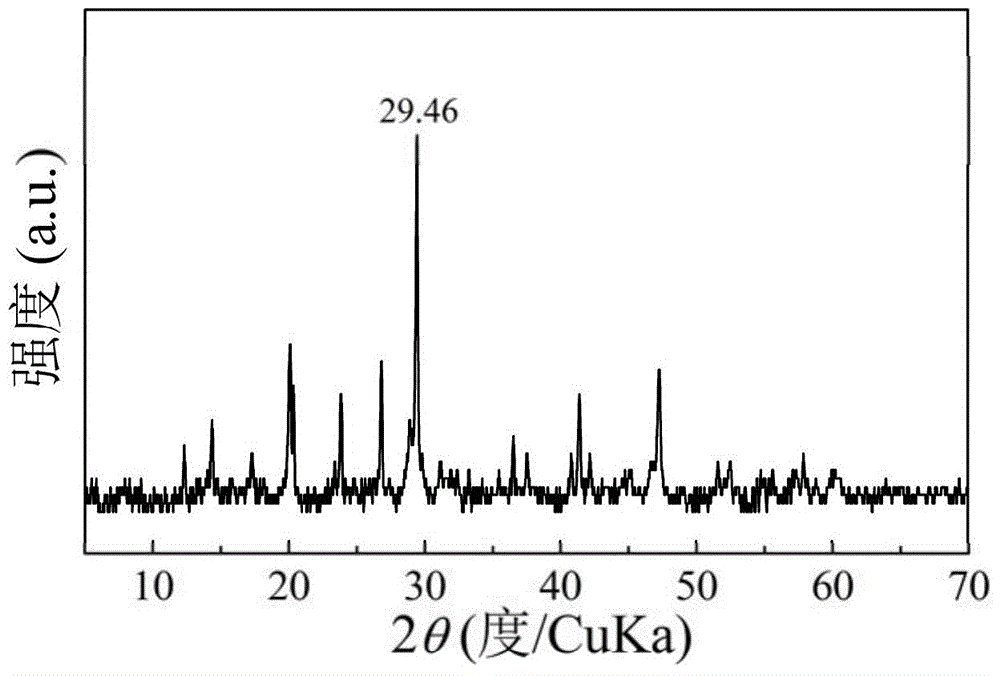

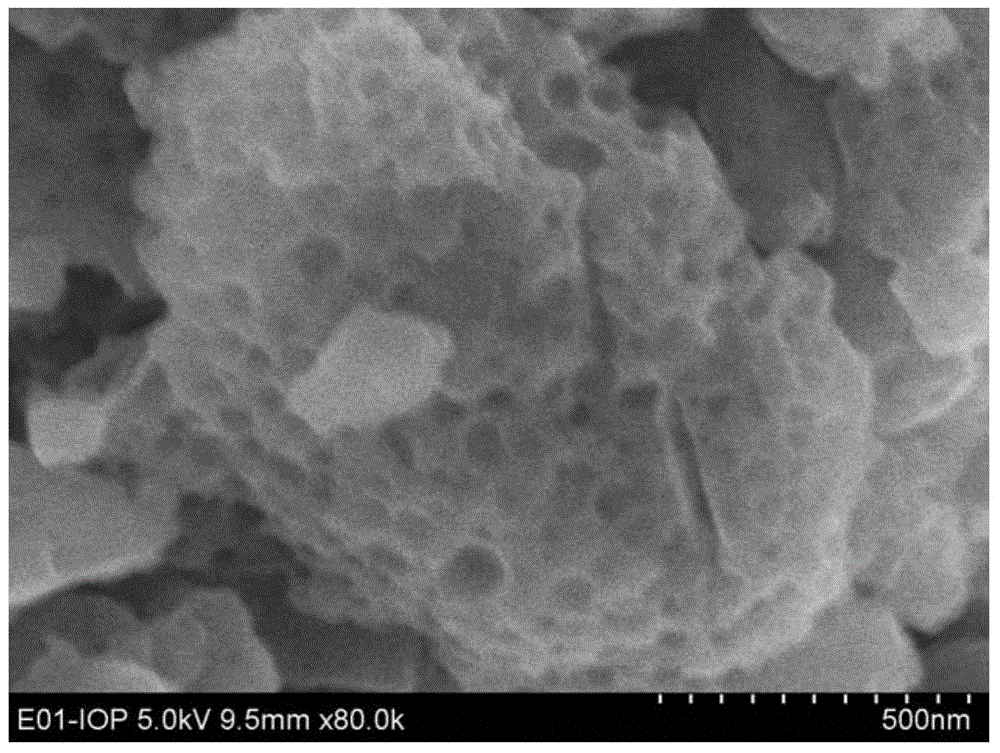

[0057] Under the protection of argon atmosphere and at room temperature, Li with a purity of more than 99% 2 S, P 2 S 5 with GeS 2 After weighing according to the molar ratio of 5:1:1, put it into the reaction vessel under the condition that the water content is less than 100ppm, and then add acetonitrile (AN) according to the mass ratio of 300%. AN needs to be distilled multiple times with a rotary evaporator to make its water content less than 1%. Add AN and mix evenly to obtain the first primary material. After the first primary material is magnetically stirred at room temperature for 24 hours, a suspension with white precipitate is obtained, which is the second primary material; Centrifuge and separate for 10 minutes, then filter and wash at room temperature, repeat this step 3 times to obtain the fourth primary material; put the fourth primary material in an oven, dry at 100°C for 10 hours to obtain a white solid, that is, the fifth primary material; The initial mater...

Embodiment 2

[0065] Under the protection of argon atmosphere and room temperature, Li with a purity of more than 99% 2 S, P 2 S 5 with GeS 2 After weighing according to the molar ratio of 5:1:1, put it into a reaction vessel under the condition that the water content is less than 100ppm, and then add tetrahydrofuran (THF) according to the mass ratio of 300%. THF needs to be distilled multiple times with a rotary evaporator to make its water content less than 1%. After adding the THF solution, the first raw material is obtained, and after magnetically stirring the first raw material at room temperature for 24 hours, a suspension with white precipitate is obtained, which is the second raw material; Centrifuge and separate for 10 minutes, then filter and wash at room temperature, repeat this step 3 times to obtain the fourth primary material; put the fourth primary material in an oven, and dry it at 120°C for 10 hours to obtain a white solid, which is the fifth primary material; Put the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com