Flash type electrical storage material and preparation method of electrical storage device

A technology for electric storage and devices, which is applied in the field of preparation of Flash-type electric storage materials and electric storage devices, can solve problems such as chip size reduction, and achieve the effects of reduced error rate, low cost, and high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0032] The technical solution of the present invention is not limited to the following specific embodiments, but also includes any combination of the specific embodiments.

specific Embodiment approach 1

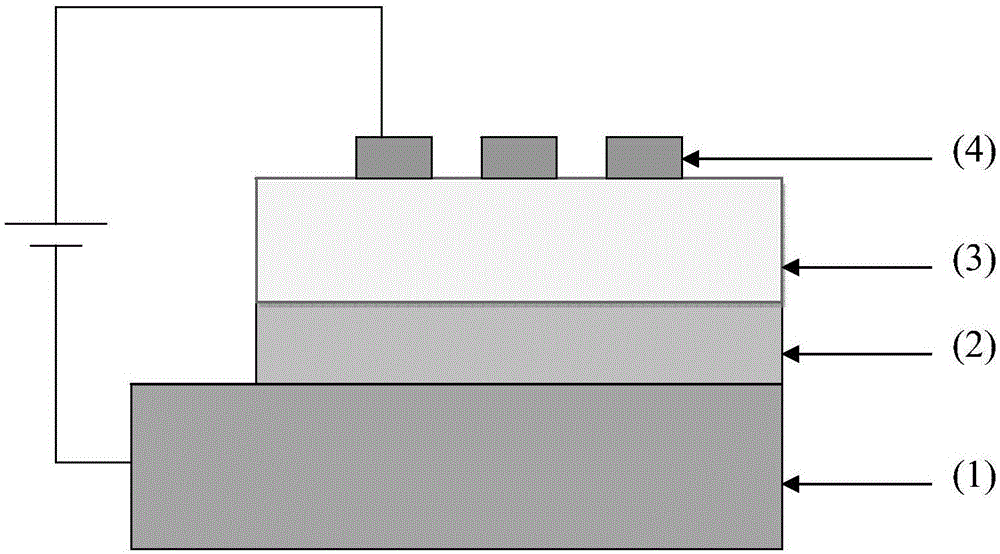

[0033] Specific Embodiment 1: In this embodiment, a method for preparing a memory device based on a fluorene-triphenylamine conjugated polymer is realized in the following steps:

[0034] Step 1, ultrasonically clean the ITO glass in reagent a, and store it in absolute ethanol for later use;

[0035] Step 2, dissolving the fluorene-triphenylamine conjugated polymer or the mixture of the conjugated polymer and the organic small molecule electron acceptor in chlorobenzene, stirring and ultrasonically dispersing (the concentration is 3-15 mg / mL);

[0036] Step 3. Spin-coat the polymer solution evenly on the ITO glass through a homogenizer, and dry in vacuum to remove the solvent; the thickness of the polymer film is 20-100nm;

[0037] Step 4: Cover the surface of the polymer with a copper sheet having holes with uniform size distribution, and plate the top electrode Al on the polymer by evaporation. The thickness of the top electrode Al is 200-400 nanometers; the area of the t...

specific Embodiment approach 2

[0038] Embodiment 2: This embodiment is different from Embodiment 1 in that the organic solvent a in step 1 is deionized water, absolute ethanol, acetone, absolute ethanol, and deionized water. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com