High-voltage power device and forming method thereof

A high-voltage power device and device technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as unstable withstand voltage, reduced current capacity of devices, and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

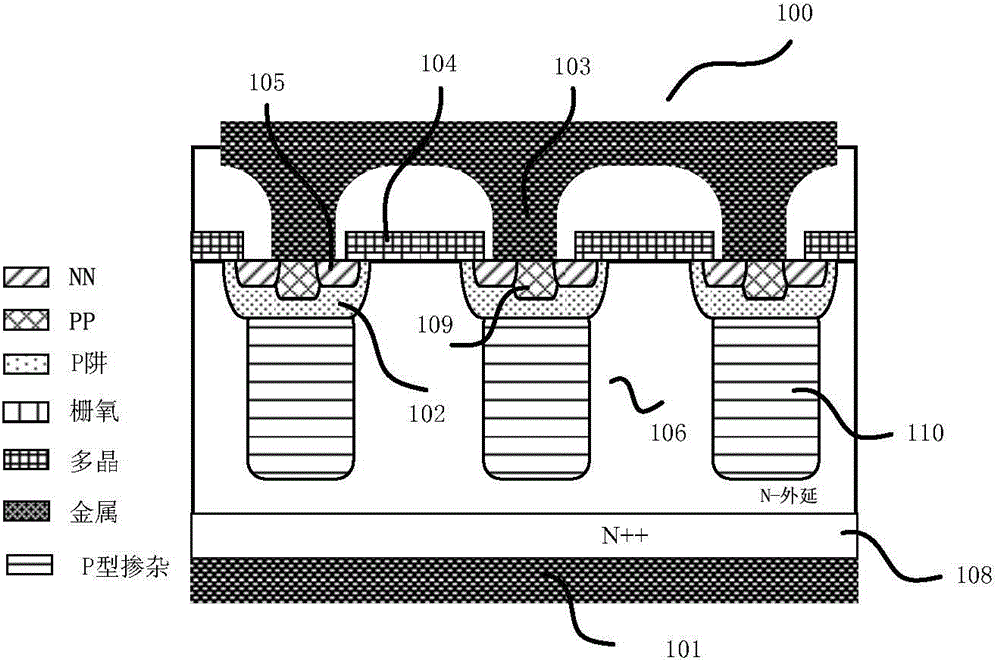

[0129] refer to image 3 , image 3 The shown high-voltage power device 300 is a high-voltage MOS device, which mainly includes: an N-type first doped region 306 located on an N-type doped substrate 308; a first electrode 301 connected to the first doped region via the substrate 308 The impurity region 306 is in electrical contact; a plurality of P-type well regions 302 are arranged laterally in the upper surface of the first doped region 306; the P-type second doped region 310 has one end connected to the well region 302 and the other end Extend vertically into the first doped region 306; the N-type device doped region 305 and the P-type device doped region 309 are formed in the well region 302, and the second doped region 310 is connected to the P-type doped region through the well region 302. The device doping region 309 is in electrical contact; the gate 304 is formed on the upper surface of the first doping region 306; the second electrode 303 is in contact with the N-ty...

no. 2 example

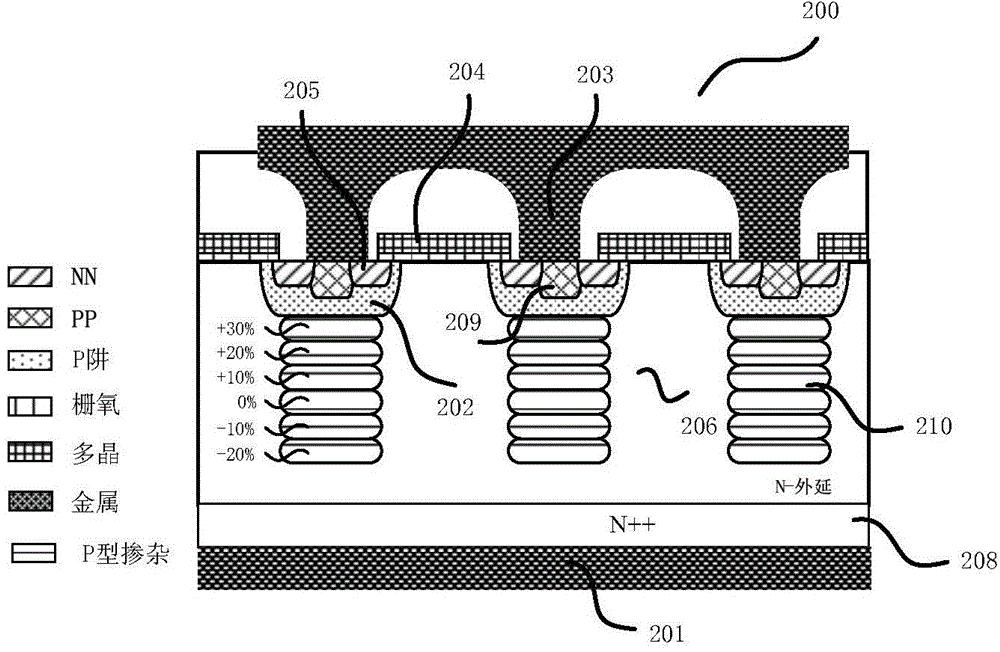

[0136] refer to Figure 4 , Figure 4 The shown high-voltage power device 400 is a high-voltage MOS device, and its structure is the same as image 3 Basically the same, including: an N-type first doped region 406 located on an N-type doped substrate 408; a first electrode 401 electrically contacting the first doped region 406 via the substrate 408; a plurality of P-type The well region 402 is horizontally arranged in the upper surface of the first doped region 406; the P-type second doped region 410 has one end connected to the well region 402, and the other end extends vertically into the first doped region 406; The N-type device doping region 405 and the P-type device doping region 409 are formed in the well region 402, and the second doping region 410 is in electrical contact with the P-type device doping region 409 via the well region 402; the gate 404 is formed on the upper surface of the first doped region 406 ; the second electrode 403 is in electrical contact with t...

no. 3 example

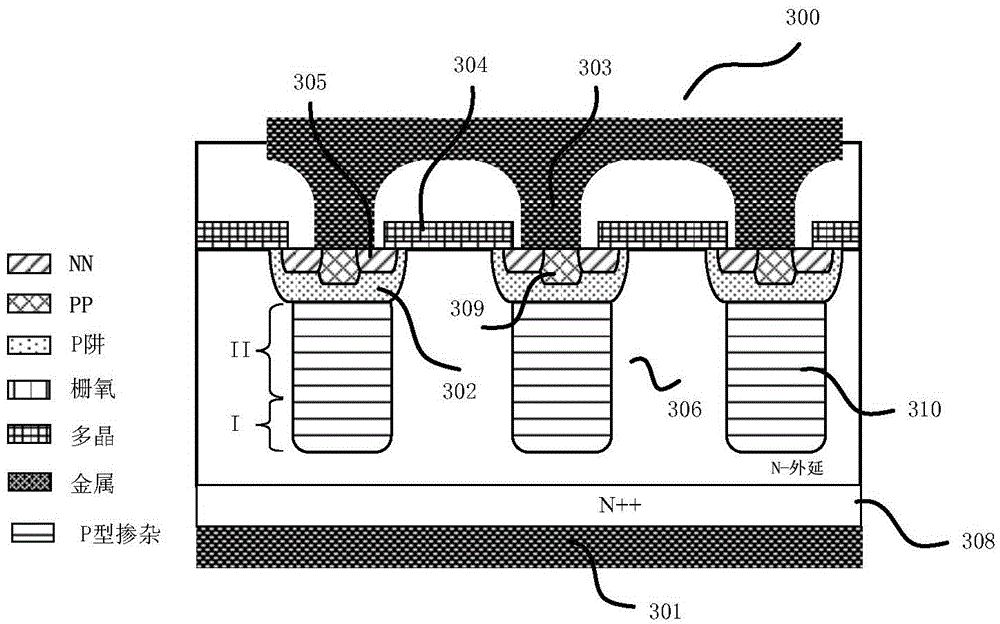

[0154] refer to Figure 12 , Figure 12 The shown high-voltage power device 800 is a high-voltage MOS device, and its structure is the same as image 3 Basically the same, including: an N-type first doped region 806 located on an N-type doped substrate 808; a first electrode 801 electrically contacting the lower surface of the first doped region 806 via the substrate 808; a plurality of The P-type well region 802 is horizontally arranged in the upper surface of the first doped region 806; the P-type second doped region 810 is connected to the well region 802 at one end and extends vertically to the first doped region at the other end. 806; the N-type device doping region 805 and the P-type device doping region 809 are formed in the well region 802, and the second doping region 810 is in electrical contact with the P-type device doping region 809 via the well region 802 The gate 804 is formed on the upper surface of the first doped region 806 ; the second electrode 803 is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com