Display panel and display device

A display panel and display device technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of high impedance of signal wires, affecting display, heating of lines, etc., and achieve the effect of increasing current channels, improving yield rate, and preventing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

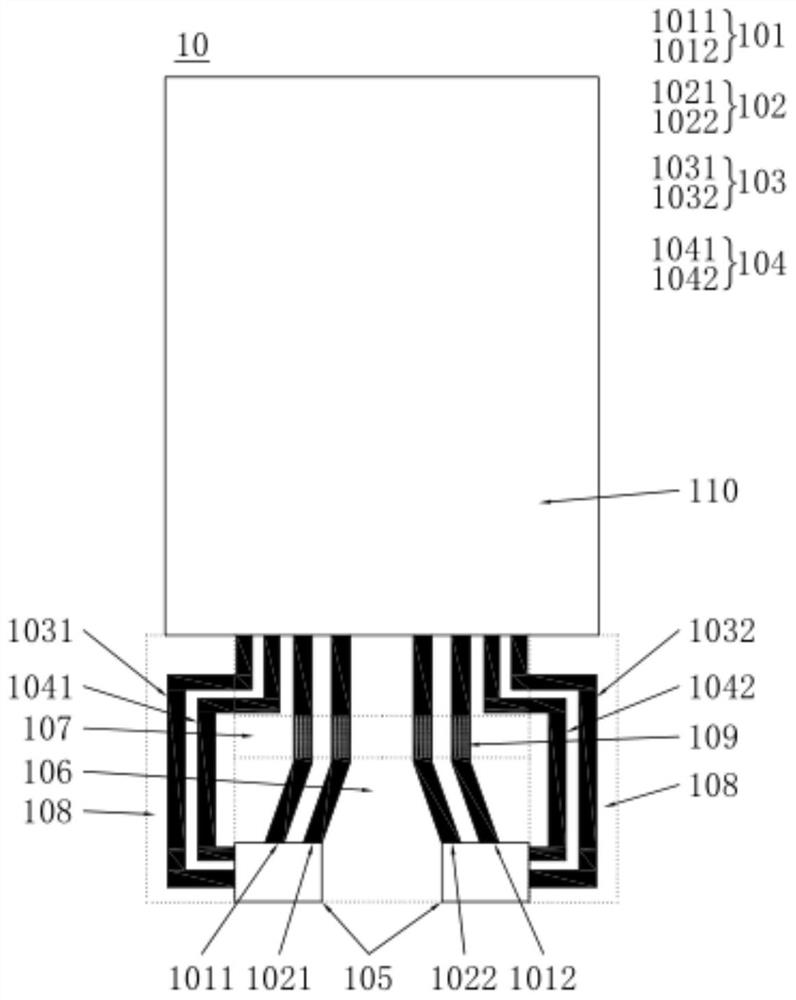

[0069] Please refer to figure 1 As shown, the display panel 10 includes a display area 110 and a non-display area surrounding the display area, the non-display area includes a terminal area 106 disposed on one side of the display area 110, and a terminal area 106 disposed in the terminal area Resection area 108 on both sides of 106 .

[0070] The terminal area 106 is provided with signal wires 101, 102, and the signal wires 101, 102 connect the TFT layer in the display area 110 with the functional circuit in the terminal area 106, which mainly includes the first A VDD trace 1011 , a second VDD trace 1012 , a first VSS trace 1021 and a second VSS trace 1022 .

[0071] The display panel 10 further includes auxiliary wires 103 and 104, and the auxiliary wires 103 and 104 are arranged in the cutout area 108, extend into the terminal area 106, and are connected in parallel with the signal wires 101 and 102. It mainly includes a first VDD auxiliary line 1031 corresponding to the f...

Embodiment 2

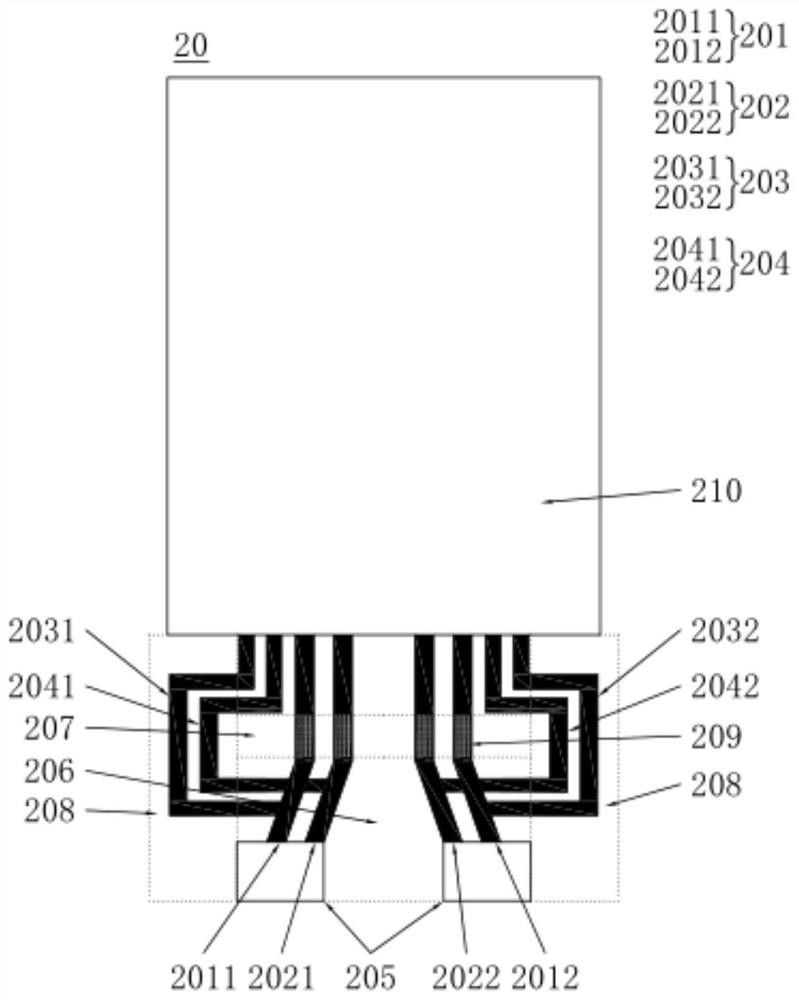

[0077] Please refer to figure 2 As shown, the display panel 20 includes a display area 210 and a non-display area surrounding the display area 210, the non-display area includes a terminal area 206 disposed on one side of the display area 210, and a terminal area 206 disposed on the terminal Cutout regions 208 on either side of region 206 .

[0078] The terminal area 206 is provided with signal wires 201 and 202, and the signal wires 201 and 202 connect the TFT layer in the display area 210 with the functional circuits in the terminal area 206, which mainly include the first A VDD trace 2011 , a second VDD trace 2012 , a first VSS trace 2021 and a second VSS trace 2022 .

[0079] The display panel 20 further includes auxiliary wires 203, 204, and the auxiliary wires 203, 204 are disposed in the cutout area 208, extend into the terminal area 206, and are connected in parallel with the signal wires 201, 202, It mainly includes a first VDD auxiliary line 2031 corresponding to ...

Embodiment 3

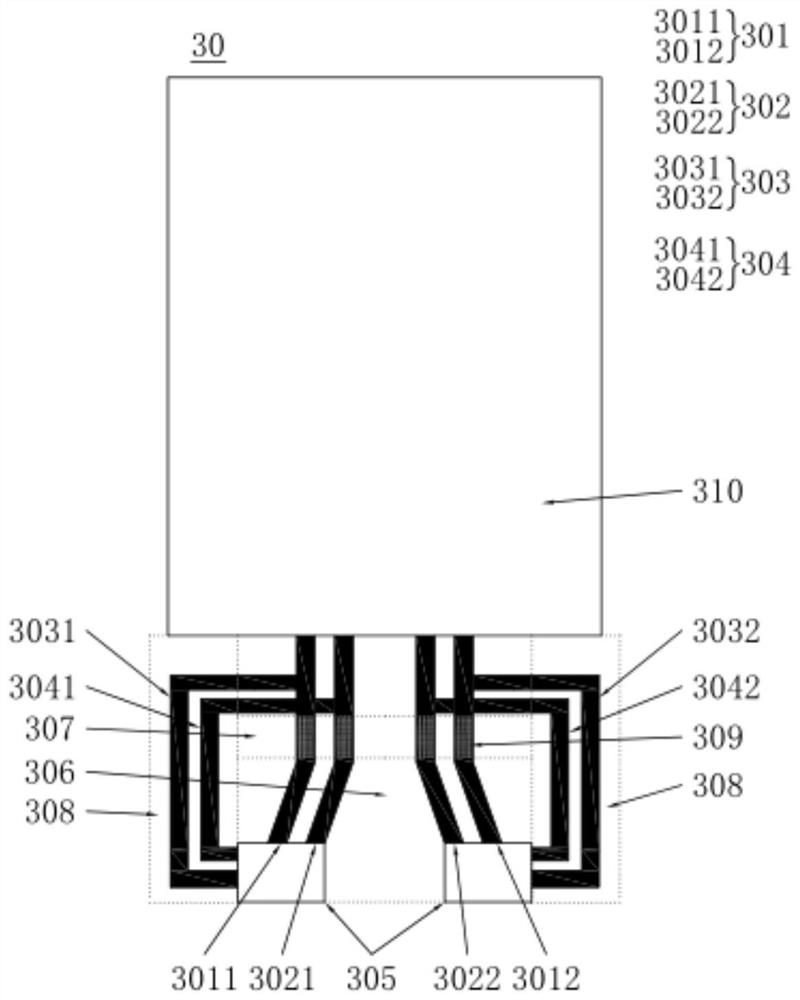

[0086] Please refer to image 3 As shown, the display panel 30 includes a display area 310 and a non-display area surrounding the display area 310, the non-display area includes a terminal area 306 disposed on one side of the display area 310, and a terminal area 306 disposed on the terminal Cutout regions 308 on either side of region 306 .

[0087] The terminal area 306 is provided with signal wires 301, 302, and the signal wires 301, 302 connect the TFT layer in the display area 310 with the functional circuit in the terminal area 306, which mainly includes the first A VDD trace 3011 , a second VDD trace 3012 , a first VSS trace 3021 and a second VSS trace 3022 .

[0088] The display panel 30 further includes auxiliary wires 303, 304, and the auxiliary wires 303, 304 are disposed in the cutout area 308, extend into the terminal area 306, and are connected in parallel with the signal wires 301, 302, It mainly includes a first VDD auxiliary line 3031 corresponding to the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com