Method for detecting content of substitutional carbon and interstitial oxygen in monocrystalline silicon

A technology for substituting carbon and single crystal silicon, which is used in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of unmeasurable substituted carbon and interstitial oxygen content, and achieves reduction of interference fringes, improvement of measurement accuracy, reduction of Scattering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Taking the measurement of substituent carbon and interstitial oxygen content of single crystal silicon produced by China Shanghai Junhe Electronic Materials Co., Ltd. as an example, the content of the present invention will be described in detail. The thickness of the sample silicon wafer is 100 μm, the silicon wafer is cut into a rectangle, 1.6cm×5cm, the crystal type is , the doping type is n-type, phosphorus doped, and the resistivity is 15Ω·cm silicon wafer, referred to as CZ silicon wafer ; The reference silicon wafer does not contain carbon and oxygen, and its resistivity is 3000Ω·cm. The rest is the same as the sample silicon wafer, referred to as FZ silicon wafer. The flatness is less than 1 / 4 of the wavelength of the incident infrared light to avoid the influence of silicon lattice vibration in the carbon absorption band, and the transmittance at the absorption peak is not lower than 20% to reduce the scattering of infrared light. Application No. 200610097859.4...

Embodiment 2

[0114] The thickness of the sample silicon wafer is 200 μm, the rest of the parameters of the sample silicon wafer and the reference silicon wafer, the detection method and steps are the same as in Example 1, and Table 2 shows the carbon and oxygen content in the 200 μm silicon wafer measured by the MTR-IR method.

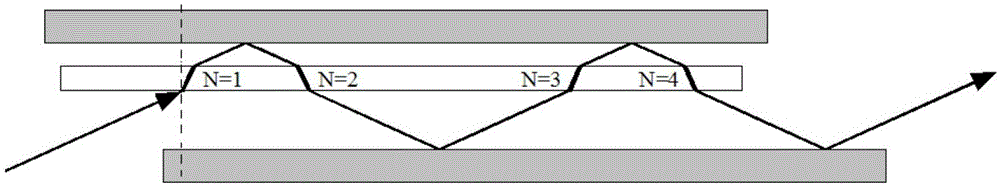

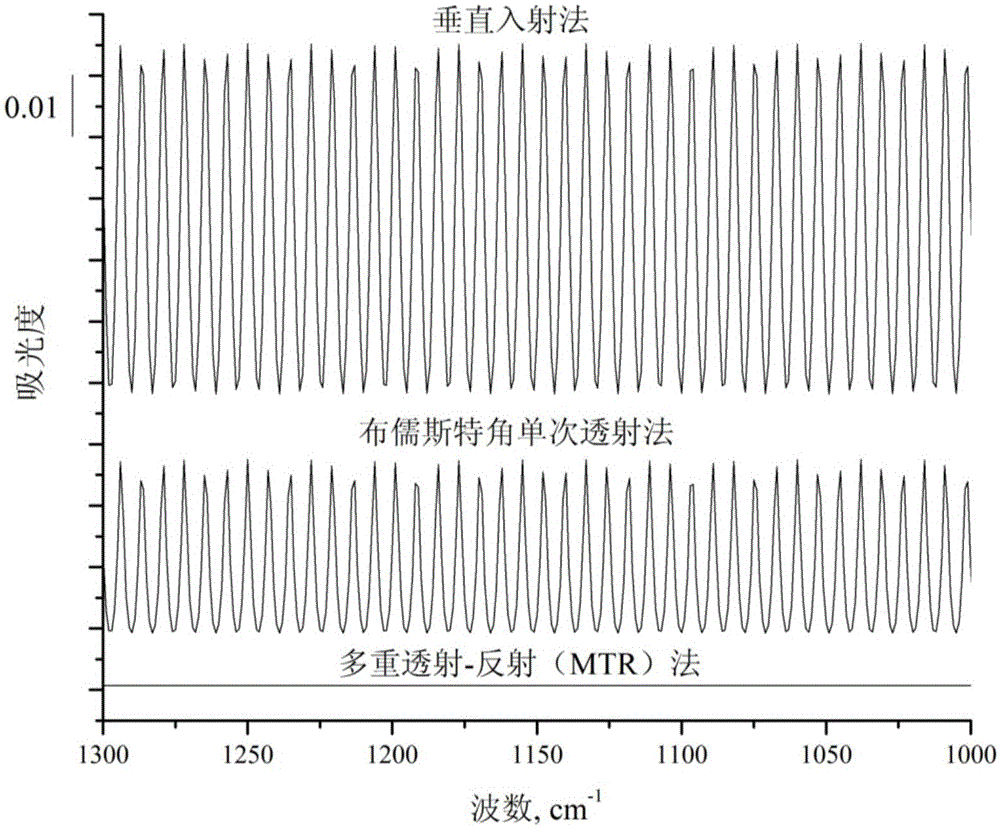

[0115] Interference reduction effect of Brewster's angle

[0116] Figure 11 It is a schematic diagram of the multiple transmission-reflection (MTR) accessory and the infrared light path; figure 1 is a schematic diagram of the optical path of P-polarized light transmission and reflection, figure 1 From top to bottom in the figure are the gold mirror, the silicon wafer and the gold mirror. In the lower left corner of the figure, the incident light, that is, the p-polarized light in the figure, is incident on the surface of the silicon wafer at the Brewster angle (ie 74°), and passes through the silicon wafer. It reaches the reflection on the gold mirror at the t...

Embodiment 3

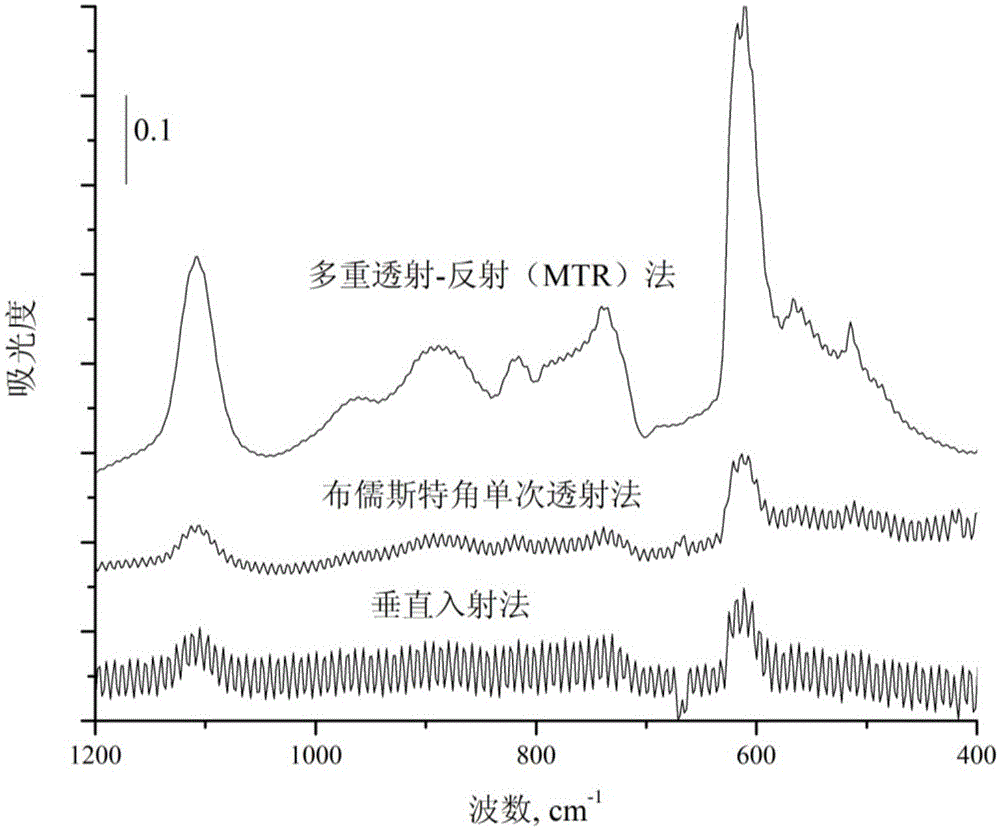

[0125] Except that the thickness of the sample and the reference silicon wafer is 450 μm, other parameters, detection methods and steps are the same as in Example 1. Image 6 Among them, MTR-sample represents the spectrogram of the sample silicon wafer measured by the MTR-IR method; IR-sample represents the spectrogram of the sample silicon wafer measured by the vertical incidence IR method, the sample length is 5cm, n=3.42, N=10, b=0.0450 cm,b B =0.0469cm,b TMR = 0.469 cm, incident angle = 74°. Image 6 The infrared spectra of the MTR-IR method and the vertical incidence IR method of the same silicon wafer are given. By comparison, it can be seen that the sample absorbance of the MTR-IR method is always greater than that of the vertical incidence IR method, especially at the gap oxygen peak 1107cm -1 and substituting carbon peak 605cm -1 , the contrast between the MTR-IR method and the vertical incidence IR method in terms of peak height or peak area is very obvious. In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com