Method for evaluating sulfur corrosion state of transformer copper coil

A technology of copper coils and transformers, which is applied in the fields of weather resistance/light resistance/corrosion resistance, instruments, scientific instruments, etc., can solve the safety hazards and detection problems of copper coils, achieve fast methods, avoid transformer damage, good economic benefits and safety benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) The sulfur element content in a 110kV transformer oil was detected twice at intervals of 3 years by plasma emission spectroscopy to be 500mg / kg and 400mg / kg;

[0039] (2) The difference between the two detections of sulfur element concentration is 100 mg / kg;

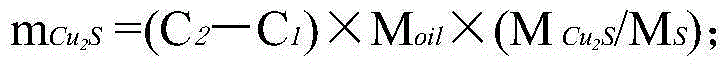

[0040] (3) The oil weight of this transformer is 20 tons, and the mass of cuprous sulfide can be calculated according to the formula to be 10kg;

[0041] (4) The volume of cuprous sulfide is 1.8L, and the total surface area of the coil copper wire obtained from the query data is 264m 2 , the calculated thickness of cuprous sulfide is 6800nm;

[0042] (5) According to the classification of risk level, the transformer is in high risk level A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com