Labor-saving linkage positioning and locking structure

A positioning locking and locking mechanism technology, applied in the direction of brake actuators, brake parts, brake types, etc., can solve the problems of small locking stroke, small starting force of roller, large operating torque, etc., to prevent ratchet reverse The effect of small rotation, small driving force and small starting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

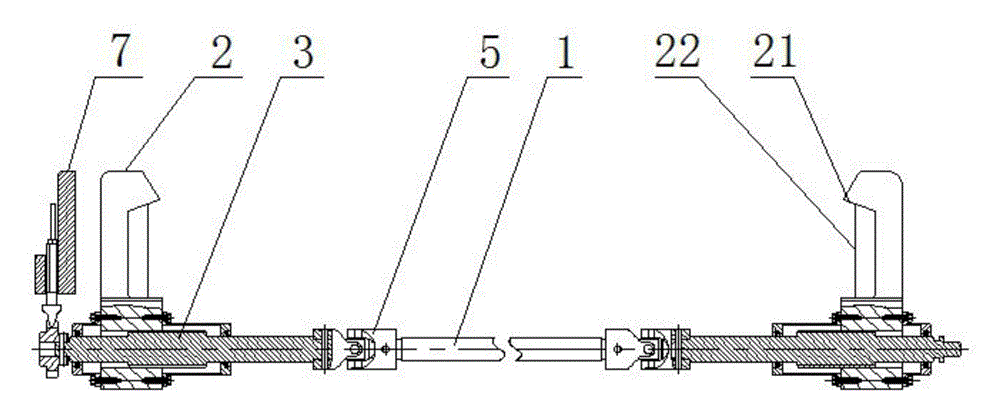

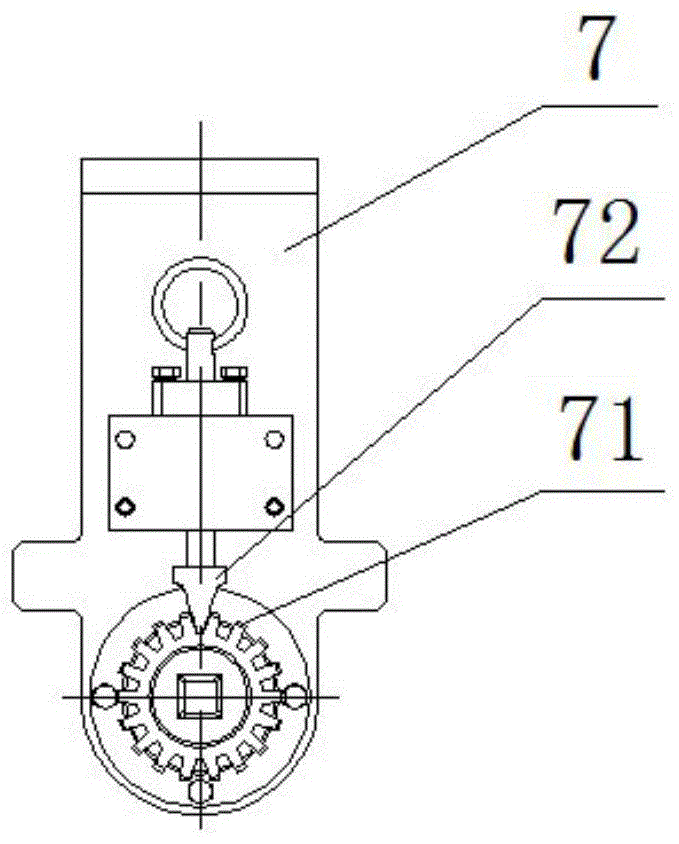

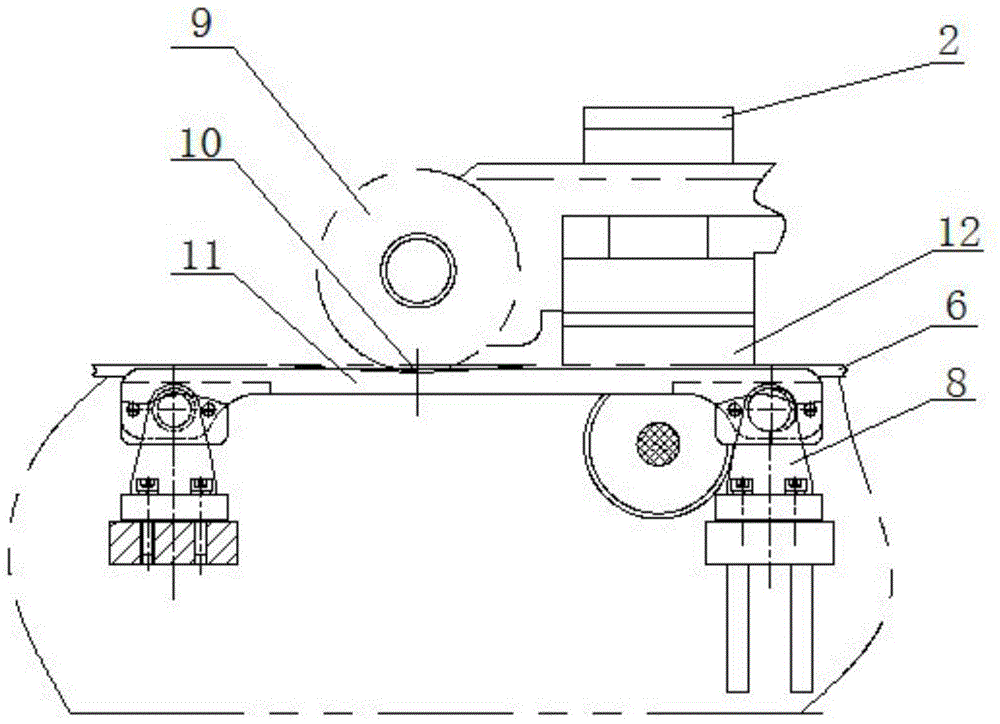

[0021] Such as Figure 1~4 As shown, a labor-saving linkage positioning and locking structure, including connecting rod 1, claw 2, screw rod 3, frame 4, cross universal joint 5, guide rail 6, locking mechanism 7, spring support seat 8, positioning groove 10 and leaf spring 11.

[0022] The guide rail 6 is horizontally installed on the frame 4, and the guide rail 6 is provided with a positioning groove 10, and the positioning groove 10 is a V-shaped groove; the side of the frame is provided with a spring support seat 8, and the spring support seat 8 is provided with a steel plate Spring 11, described leaf spring 11 is juxtaposed parallel with guide rail 6; In order to reduce the horizontal force of leaf spring 11 to spring support seat 8, the connection hole of leaf spring 11 one end is designed as waist-shaped hole.

[0023] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com