Polyurethane waterproof roll, production equipment and process, composite waterproof layer and practice thereof

A technology of polyurethane waterproofing and waterproofing layer, which is applied in the field of composite waterproofing layer, production equipment and production process of waterproofing membrane, and waterproofing membrane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

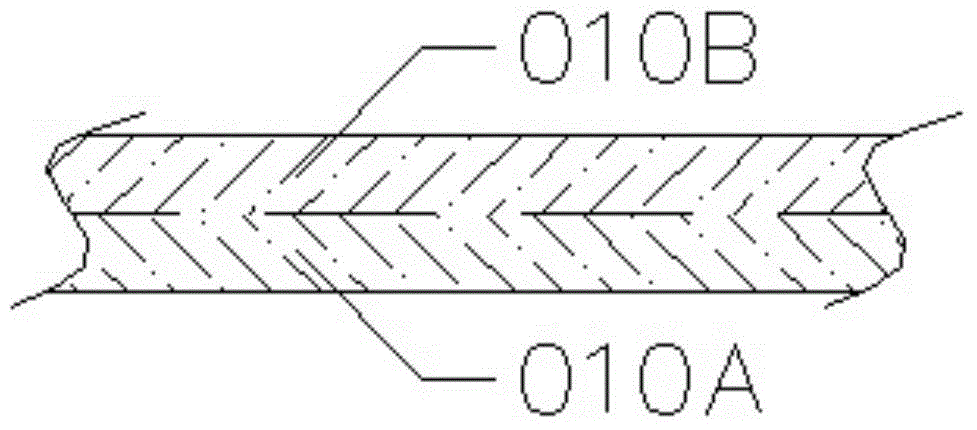

[0144] Example 1-1: As shown in the figure, figure 2 It is the structure diagram of the basic type of polyurethane waterproof coiled material of the present invention; in the figure: 0201-polyurethane waterproof coating.

[0145] A basic type 001 polyurethane waterproof membrane: a single-layer solid polyurethane waterproof membrane; in a specific embodiment, the thickness of the polyurethane waterproof membrane is 0.4mm, 0.5mm, 0.6mm, 0.7mm, 0.8mm, 0.9 mm, 1.0mm, 1.1mm, 1.2mm, 1.3mm, 1.4mm, 1.5mm, 1.6mm, 1.7mm, 1.8mm, 1.9mm, 2.0mm, 2.1mm, 2.2mm, 2.3mm, 2.4mm, 2.5mm, 2.6mm, 2.7mm, 2.8mm, 2.9mm, 3.0mm, 3.1mm, 3.2mm, 3.3mm, 3.4mm, 3.5mm, 3.6mm, 3.7mm, 3.8mm, 3.9mm, 4.0mm, 4.1mm, 4.2mm , 4.3mm, 4.4mm. This type can be used for ordinary waterproof and moisture-proof.

Embodiment 1-2

[0146] Embodiment 1-2: A 002 basic type polyurethane waterproof membrane: superposition or gluing of two or more layers of solid polyurethane waterproof membrane.

Embodiment 1-3

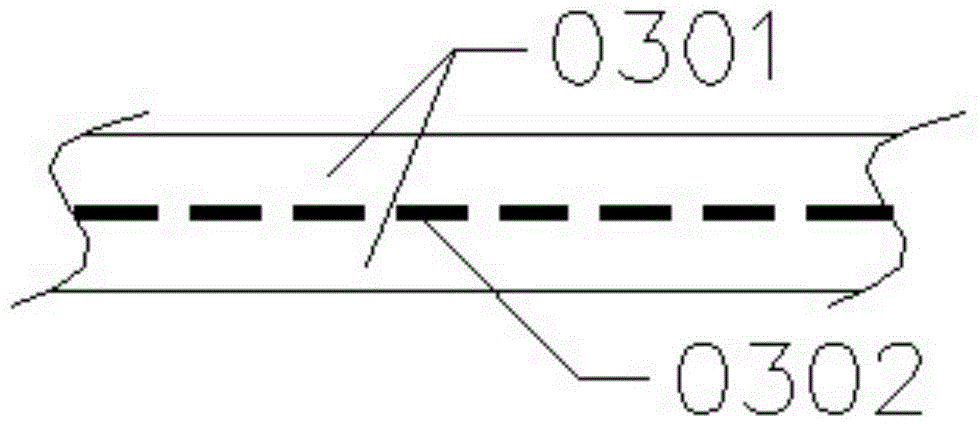

[0147] Embodiment 1-3: As shown in the figure, image 3 It is the extended type one of the polyurethane waterproof membrane referred to in the patent of the present invention. In the figure: 0301-solid polyurethane waterproof material layer; 0302-carcass reinforcement material (chemical fiber non-woven fabric, chemical fiber mesh cloth, glass fiber mesh cloth and composite materials, etc.).

[0148] A type 003 polyurethane waterproof coiled material: the solid polyurethane waterproof material layer (0301) is embedded or permeated with a carcass reinforcing material (0302) during production, and the carcass reinforcing material is chemical fiber non-woven fabric, chemical fiber grid cloth, glass One or two or more of fiber mesh cloth and other carcass reinforcement materials or composite materials formed by multiple carcass reinforcement materials; the tensile strength, tear strength, impact resistance, and Breakability is improved compared to the basic type.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com