A bubble electrospinning device

A technology of bubble electrospinning and bubble generating device, applied in the field of spinning, can solve the problems of small number of bubbles and difficult control of droplets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

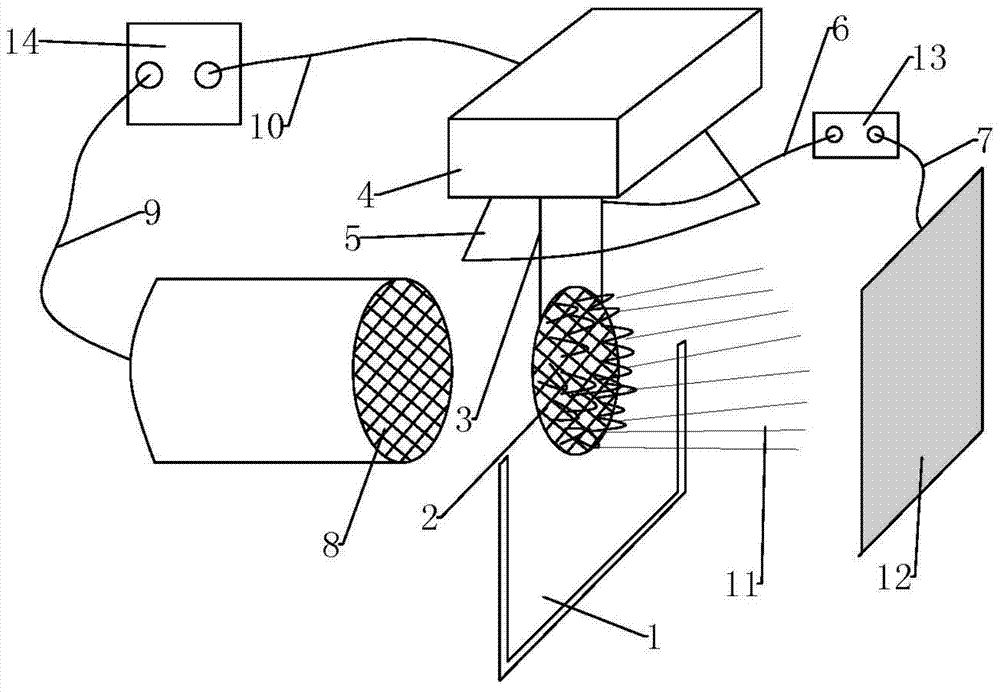

[0031] The invention discloses a bubble electrospinning device, which is used to solve the problems that the number of bubbles in the bubble generating device is small and the droplet is difficult to control in the spinning process. In this bubble electrospinning device, firstly, the bubble generating device is set as a mesh structure, which increases the number of polymer films, thereby increasing the number of bubbles and increasing the output; secondly, the blowing port at the front end of the blowing device is connected The corresponding mesh structure ensures that the polymer film on the mesh of the bubble generating device forms bubble protrusions; moreover, the airflow generated by the blowing device takes away the polymer droplets attached to the bubble generating device, making the receiving plate The fiber morphology is more uniform. The invention has the advantages of simple structure, convenient operation, simple control and short technological process.

[0032] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com