Low-toxicity oil base microbubble drilling fluid for protecting hydrocarbon reservoir

A technology for oil and gas reservoirs and drilling fluids, which is applied in the field of low-toxicity oil-based microbubble drilling fluids to protect oil and gas reservoirs, and can solve problems such as high base fluid density, limited application, and impact on drilling fluid stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

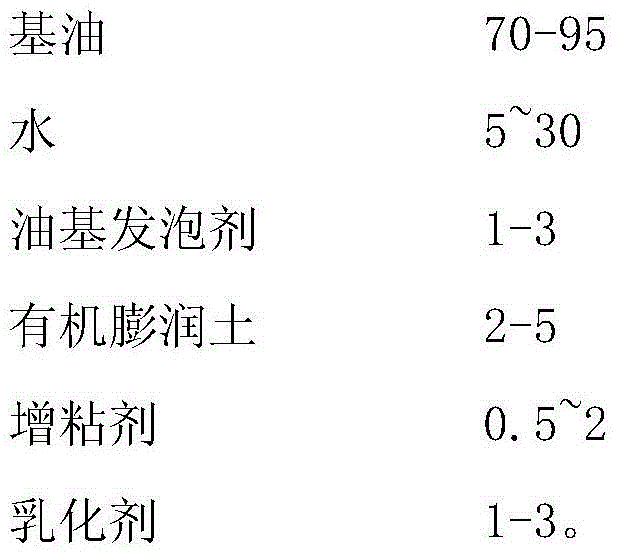

[0093] Get 70 kilograms of white oil and 30 kilograms of distilled water, add 1 kilogram of sorbitan fatty acid ester emulsifier and 5 kilograms by the carbon number of the carbon chain in the long carbon chain alkyl quaternary ammonium salt by montmorillonite type clay mineral to be C12 modification The obtained organic bentonite was stirred for 20-30 minutes to form a base slurry; then 1 kg of oil-based foaming agent was added (mixed according to the long-chain alkyl fat calcium salt: alkyl silicone oil = 1:0.2 molar ratio) The resulting mixture) and 2 kg of butadiene rubber tackifier, fully stirred for 2-3 hours until the system is uniform.

Embodiment 2

[0095] Get 95 kilograms of white oil and 5 kilograms of distilled water, add 3 kilograms of sorbitan fatty acid ester emulsifiers and 2 kilograms by the carbon number of the carbon chain in the long carbon chain alkyl quaternary ammonium salt by montmorillonite clay mineral to be C12 modification The organobentonite that is obtained by mixing is stirred for 20-30 minutes to form a base slurry; then add 3 kg of oil-based foaming agent (mixed according to the long-chain alkyl fat calcium salt: alkyl silicone oil = 1:0.2 molar ratio) The resulting mixture) and 0.5 kg of butadiene rubber tackifier, fully stirred for 2-3 hours until the system is uniform.

Embodiment 3

[0097] Get 80 kilograms of white oil and 20 kilograms of distilled water, add 2 kilograms of sorbitan fatty acid ester emulsifiers and 3.5 kilograms by the carbon number of the carbon chain in the long carbon chain alkyl quaternary ammonium salt by montmorillonite type clay mineral to be C12 modification The organobentonite that is obtained by mixing is stirred for 20-30 minutes to form a base slurry; then add 2 kg of oil-based foaming agent (according to the long-chain alkyl fat calcium salt: alkyl silicone oil = 1:0.2 molar ratio mixed to form The resulting mixture) and 1 kg of butadiene rubber tackifier, fully stirred for 2-3 hours until the system is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com