Composition for coating core die

A technology of composition and die, which is applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as complicated operation, low finish, and reduced production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

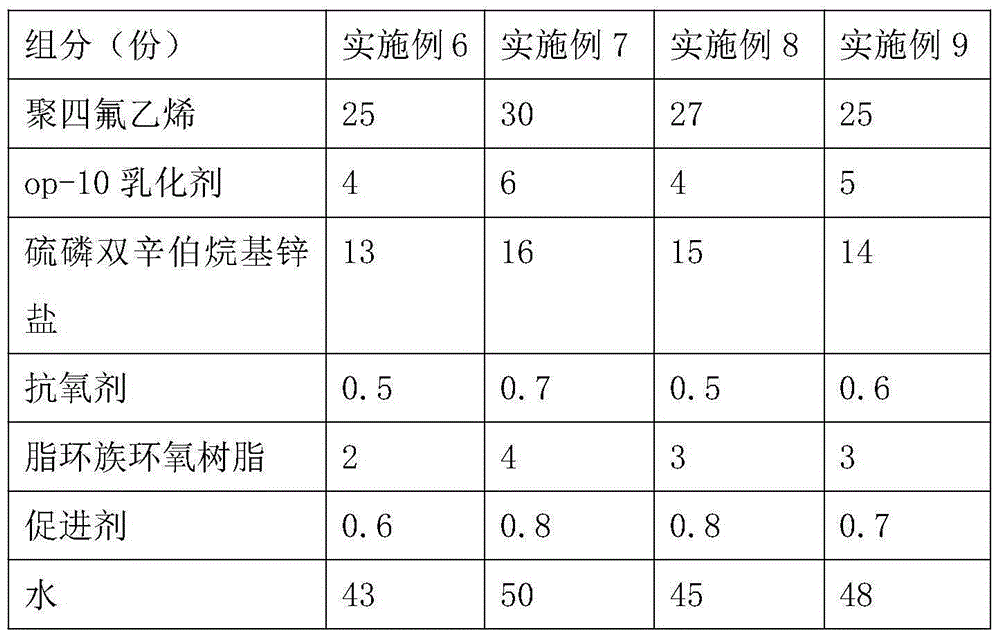

Examples

Embodiment 1

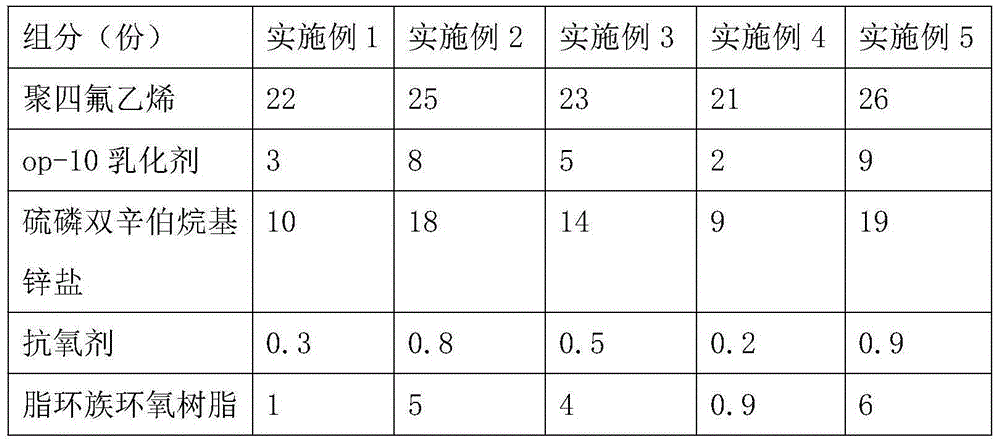

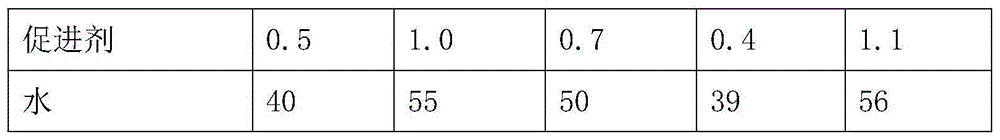

[0017] Step 1, material preparation: it consists of the following components in parts by mass: polytetrafluoroethylene: 22 parts, op-10 emulsifier: 3 parts, phosphobisoctyl zinc salt: 10 parts, antioxidant: 0.3 Parts, cycloaliphatic epoxy resin: 1 part, accelerator: 0.5 parts, water: 40 parts;

[0018] Step 2, pulverizing the polytetrafluoroethylene in step 1 into a particle size of 80 mesh;

[0019] Step 3, the polytetrafluoroethylene obtained in step 2 and the op-10 emulsifier in step 1 are placed in a stirrer and stirred at a stirring speed of 120r / min for 5min, and the mixture A is taken out;

[0020] Step 4. Add the mixture in step 3 to the water in step 1, and heat at 130° C. for 15 minutes to obtain solution B;

[0021] Step 5. Put solution B into an ultrasonic oscillator with an oscillation frequency of 80-120Khz to oscillate and disperse to obtain solution C. The ultrasonic oscillator adopts the ultrasonic oscillator model KQ-300VDE produced by Shanghai Wuxiang Instr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com