Preparation method of anti-microbial star type poly-polypeptide

The technology of polypolypeptide and antibacterial agent is applied in the field of preparation of antibacterial star-shaped polypolypeptide, which can solve the problems of being easily degraded by enzymes, complicated extraction process, difficult industrialization, etc., and achieves less toxic and side effects on human body, improved antibacterial efficiency, and easy synthesis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

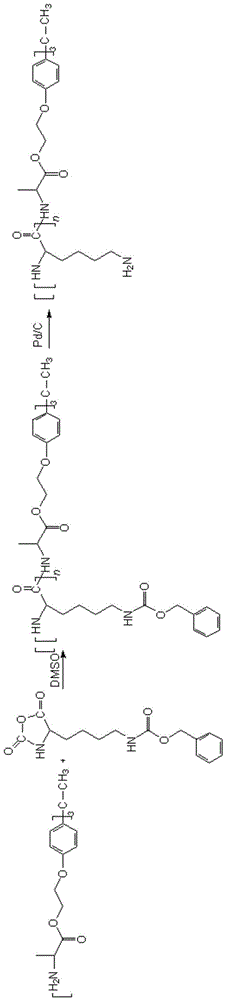

Embodiment 1

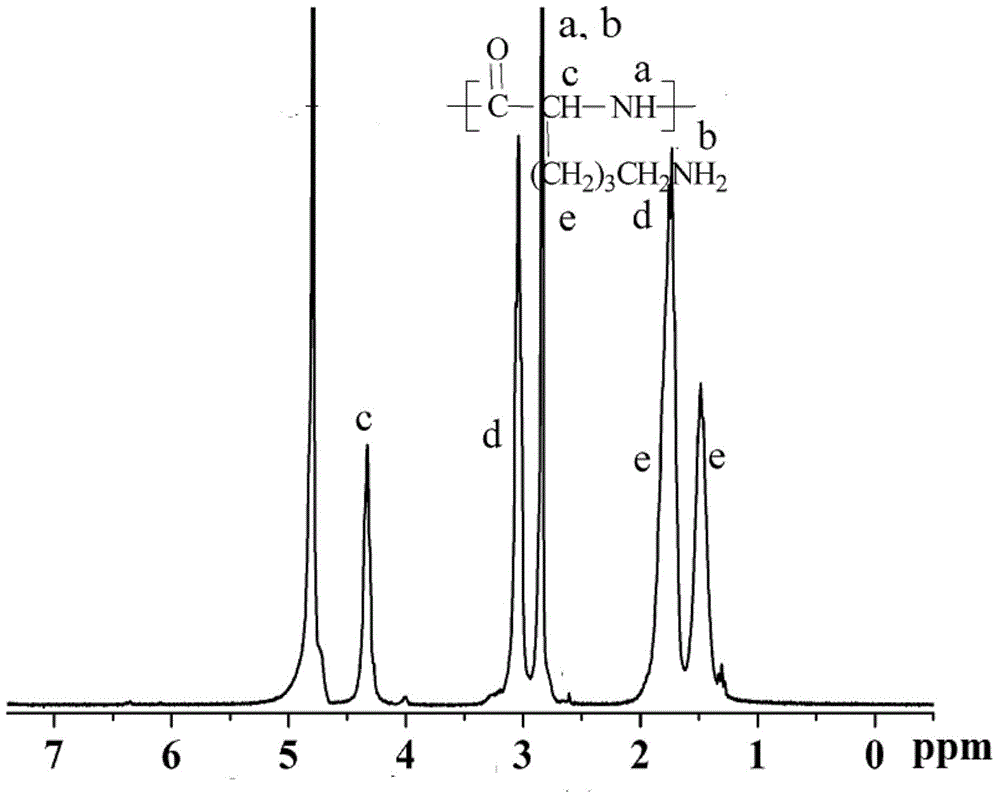

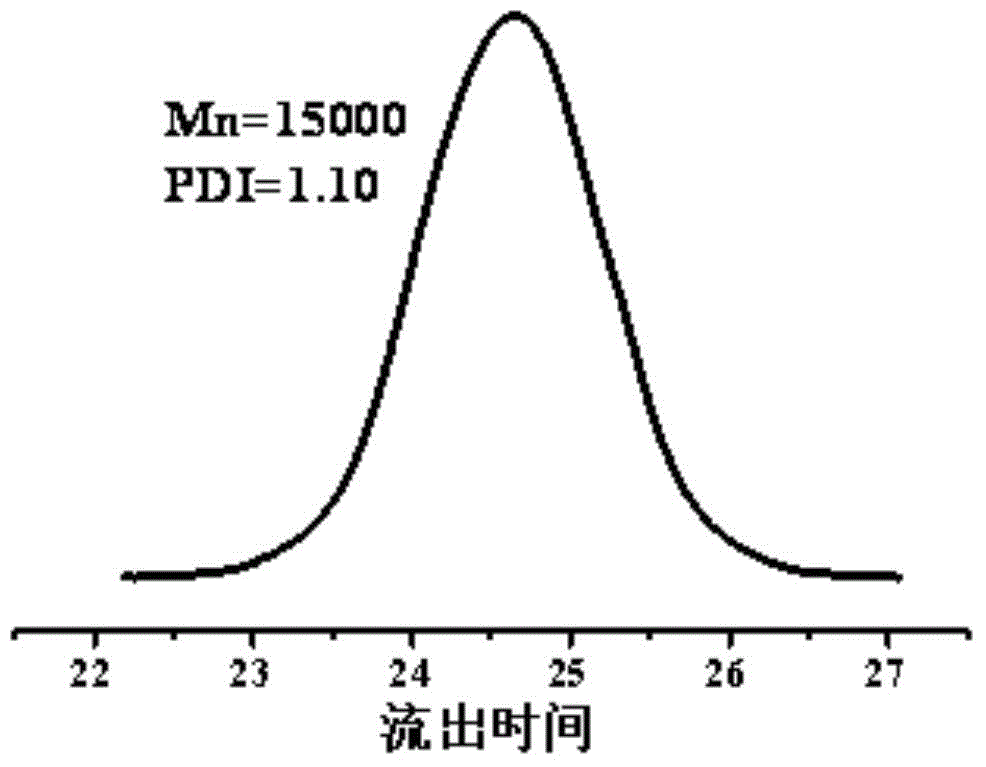

[0058] Add propargylamine: benzyl carbamate-protected N-carboxy-α-lysine anhydride: DMSO = 1:50:50 into a three-necked flask, and react with nitrogen gas for 60-70 hours. Precipitate benzylcarbamate-protected star polypeptides in water, followed by alkyne-terminated linear polypolypeptides: DMF: trifunctional azide core: CuBr: pentamethyldiethylenetriamine = 1 Add the ratio of :150:0.1:0.3:0.3 into a three-necked flask, pass nitrogen gas to react for 2-4 hours, and then precipitate in water, the resulting solid is catalyzed by palladium carbon according to the product: H2=1:3000 for reduction hydrogenation reaction, Dialyze in a 3kDa dialysis bag for one day, remove water under reduced pressure, and vacuum dry overnight to obtain pure star polypeptide, with a yield of 96%.

Embodiment 2

[0060] Add propargylamine: benzyl carbamate-protected N-carboxy-α-lysine anhydride: DMSO = 1:150:150 into a three-necked flask, and react with nitrogen for 60-70 hours. Precipitate benzylcarbamate-protected star polypeptides in water, followed by alkyne-terminated linear polypolypeptides: DMF: trifunctional azide core: CuBr: pentamethyldiethylenetriamine = 1 Add the ratio of :200:0.1:0.3:0.3 into a three-necked flask, and react with nitrogen gas for 2-4 hours, and then precipitate in water, and the resulting solid is catalyzed by palladium carbon according to the product: H2=1:3000. Reductive hydrogenation reaction, Dialyze in a 3kDa dialysis bag for one day, remove water under reduced pressure, and vacuum dry overnight to obtain pure star polypeptide, with a yield of 95%.

Embodiment 3

[0062] Add propargylamine: benzyl carbamate-protected N-carboxy-α-lysine anhydride: DMSO = 1:200:200 into a three-necked flask, and react with nitrogen gas for 60-70 hours. Precipitate benzylcarbamate-protected star polypeptides in water, followed by alkyne-terminated linear polypolypeptides: DMF: trifunctional azide core: CuBr: pentamethyldiethylenetriamine = 1 Add the ratio of :50:0.1:0.3:0.3 into the three-necked flask, pass nitrogen gas to react for 2-4 hours, and then precipitate in water, the resulting solid is catalyzed by palladium carbon according to the product: H2=1:3000 for reduction hydrogenation reaction, Dialyze in a 3kDa dialysis bag for one day, remove water under reduced pressure, and vacuum dry overnight to obtain pure star polypeptide, with a yield of 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com