A kind of C30 self-compacting micro-expansion steel pipe concrete and its preparation method

A technology of concrete-filled steel pipe and micro-expansion, which is applied in the field of construction materials and can solve problems affecting the service characteristics of steel-filled steel pipe concrete, debonding of steel pipes and core concrete, and large water-binder ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In embodiment 2~5, the preparation method of described viscosity-increasing and plastic-retaining hyperdispersive admixture comprises the following steps:

[0044] 1) Using methallyl alcohol, ammonia water and propylene oxide as raw materials, sodium methallylate or potassium methallylate as a catalyst, under the conditions of a pressure of 0.10-0.40MPaG and a temperature of 50-150°C , reacted for 3 to 7 hours to prepare a mixture of methallyl alcohol polyoxypropylene ether and triisopropanolamine, the molar ratio of the methallyl alcohol, ammonia and propylene oxide was 1:(0.2 to 0.5) : (5.0~78.0), the consumption of catalyst is 0.10~0.60% of methallyl alcohol quality;

[0045] 2) Take the mixture of methallyl alcohol polyoxypropylene ether and triisopropanolamine, sodium acrylate sulfonate, methacrylate and water prepared in step 1) as raw materials, add a reflux condenser, a thermometer and In the three-necked flask with dropping funnel, heat up to 60-90°C, add acry...

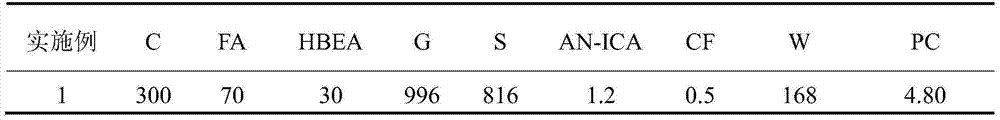

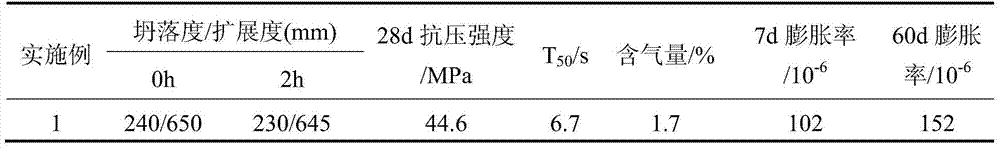

Embodiment 1

[0049] In embodiment 1, the preparation method of thickening and plastic-retaining ultra-dispersion admixture is roughly the same as embodiment 2~5, and difference is: 1) the mol ratio of methallyl alcohol, ammoniacal liquor and propylene oxide is 1:0.4: 20. The amount of catalyst used is 0.4% of the mass of methallyl alcohol, the reaction pressure is 0.30MPaG, the temperature is 105°C, and the time is 5h; 2) the reaction between methallyl alcohol polyoxypropylene ether and triisopropanolamine Mixture 86%, sodium acrylate sulfonate 3%, methacrylate 8%, water 3%; 3) The molar ratio of methacrylic acid and polypropylene glycol monomethyl ether is 1.18:1, dipropylene glycol monobutyl ether and maleic anhydride The molar ratio is 1.5:1, the reaction temperature is 120°C, and the time is 4h; 4) Polypropylene glycol monomethyl ether methacrylate monomer 82%, diethylene glycol dipropylene glycol monobutyl ether monomer 3%, methyl Acrylic acid 8%, dimethylaminoethanol 3%, sodium metha...

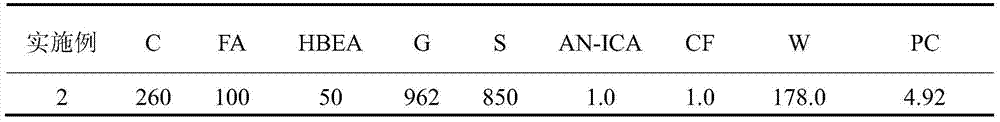

Embodiment 2

[0068] A C30 self-compacting micro-expansion concrete-filled steel tube is applied to prepare upper and lower concrete-filled steel tube chords of a concrete-filled steel tube truss bridge. The preparation method comprises the following steps:

[0069] 1) take each raw material by the proportioning described in table 3;

[0070] 2) The internal curing material is pre-absorbed. Put the internal curing material in water to absorb water at a mass ratio of 1:15. The water absorption time is 2 to 3 hours, and stir evenly;

[0071] 3) Put the weighed ordinary Portland cement, fly ash, composite expansion agent, crushed stone and river sand into the concrete mixer for dry mixing, and in the process of dry mixing, the weighed micron modified absorbent cotton cellulose Add it into the mixer, fully dry mix it evenly (2~5min), and get the dry mix; mix the pre-absorbed internal curing material with the viscosity-enhancing plastic super-dispersion additive and water, and then put it in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com